Dextromethorphan hydrobromide lyophilized powder and preparation method thereof

A technology of dextromethorphan hydrobromide and freeze-dried powder injection, applied in freeze-dried delivery, powder delivery, pharmaceutical formulations and other directions, can solve problems such as increased product cost, high product safety risk, etc., and achieves less excipients and safe clinical use. High performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

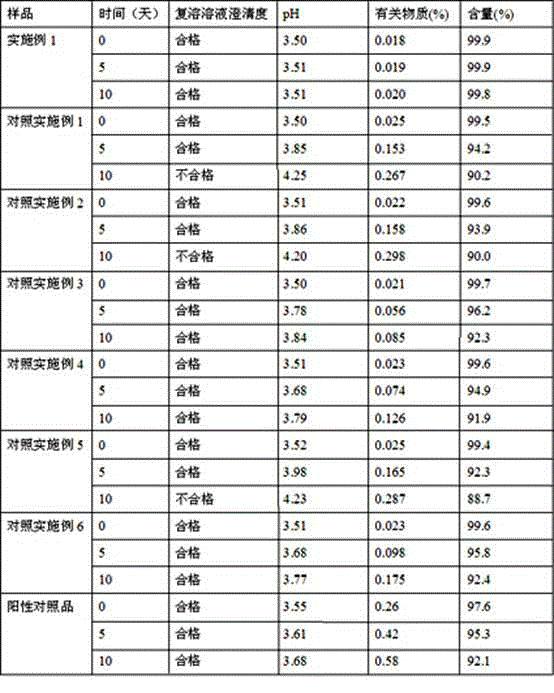

Examples

Embodiment 1

[0020] Dextromethorphan hydrobromide: 16g

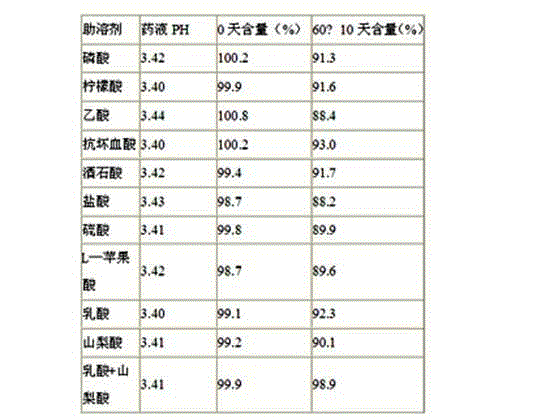

[0021] Lactic acid and sorbic acid: 11g lactic acid + 8g sorbic acid

[0022] Polyethylene glycol 2000: 45g

[0023] PH regulator: appropriate amount

[0024] Water for injection: 2000ml

[0025] Process:

[0026] 1. Take the prescribed amount of lactic acid and sorbic acid, add 50% water for injection, heat to 50-55°C, stir to dissolve, take the prescribed amount of dextromethorphan hydrobromide into the solution, stir to dissolve and continue to stir for 15 minutes .

[0027] 2. Take the prescribed amount of polyethylene glycol 2000, add 40% water for injection, stir for 15 minutes, and adjust the pH to 3.0-3.5 with hydrochloric acid.

[0028] 3. Combine solutions 1 and 2, adjust the pH to 3.3-3.6 with a pH regulator (sodium hydroxide solution), add water for injection to the full amount, add 0.15% activated carbon for needles, stir for 25 minutes, filter for decarburization, intermediate Inspection, after passing the test, u...

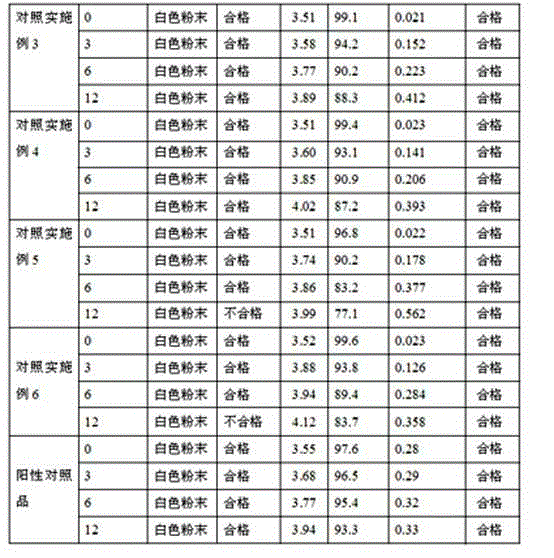

Embodiment 1

[0030] Dextromethorphan hydrobromide: 16g

[0031] Lactic acid and sorbic acid: 11g lactic acid + 8g sorbic acid

[0032] PH regulator: appropriate amount

[0033] Water for injection: 2000ml

[0034] Process:

[0035] 1. Take the prescribed amount of lactic acid and sorbic acid, add 80% water for injection, heat to 50-55°C, stir to dissolve, take the prescribed amount of dextromethorphan hydrobromide into the solution, stir to dissolve and continue to stir for 15 minutes .

[0036] 2. Use a pH regulator (sodium hydroxide solution) to adjust the pH to 3.3-3.6, add water for injection to the full amount, add 0.15% activated carbon for needles, stir for 25 minutes, filter for decarburization, check the intermediate, and use 0.22 μm after passing the test Membrane filter to sterilize, pour the filtrate into vials, and freeze-dry to obtain freeze-dried powder injections, which are packaged after passing the inspection.

Embodiment 2

[0038] Dextromethorphan hydrobromide: 16g

[0039] Polyethylene glycol 2000: 45g

[0040] pH regulator: appropriate amount

[0041] Water for injection: 2000ml

[0042] Process:

[0043] 1. Take the prescribed amount of polyethylene glycol 2000, add 80% water for injection, stir for 15 minutes, and adjust the pH to 3.0-3.5 with hydrochloric acid. Get the prescribed amount of dextromethorphan hydrobromide and add it into the solution, stir and dissolve and continue to stir for 15 minutes.

[0044] 2. Use a pH regulator (sodium hydroxide solution) to adjust the pH to 3.3-3.6, add water for injection to the full amount, add 0.15% activated carbon for needles, stir for 25 minutes, filter for decarburization, check the intermediate, and use 0.22 μm after passing the test Membrane filter to sterilize, pour the filtrate into vials, and freeze-dry to obtain freeze-dried powder injections, which are packaged after passing the inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com