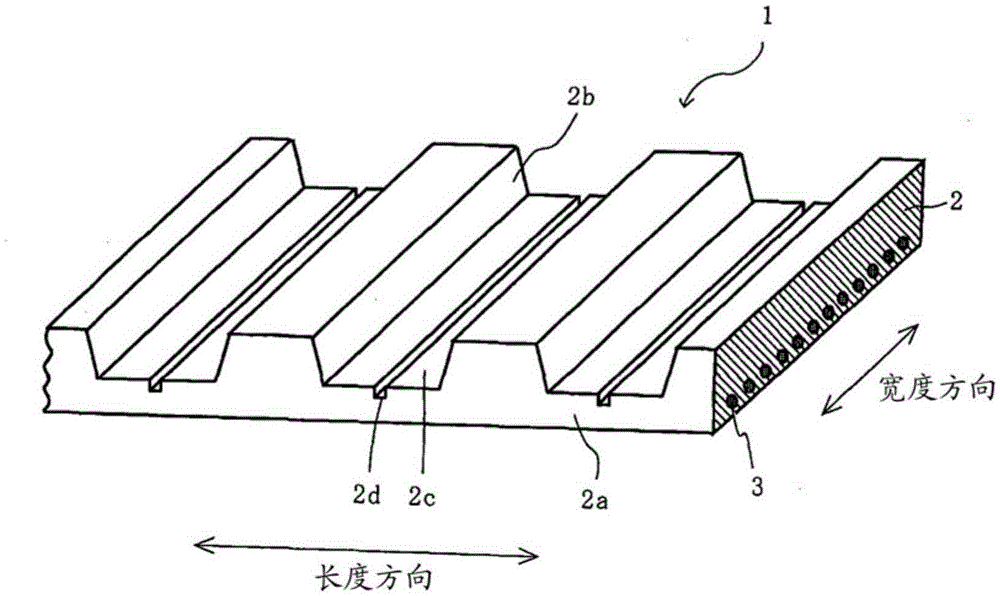

toothed belt

A toothed belt, thermoplastic elastomer technology, applied in transmission belts, belts/chains/gears, mechanical equipment, etc., can solve the problems of insufficient durability, cracks, belt body wear, etc., and achieve excellent durability and wear resistance. Excellent properties and excellent flex fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107]100 parts by weight of TPU-1 and 10 parts by weight of MAH-EPDM were kneaded using a twin-screw extruder (manufactured by Technovel, trade name "KZW20TW-30"). The extruder was set at a cylinder temperature of 200° C. (in which, the feed portion was 160° C.), and the screw rotation speed was set at 300 rpm, the above-mentioned resin was melt-kneaded, and pellets were produced by a pelletizer. The obtained pellets were injection molded using an injection molding machine (manufactured by Nissei Plastic Industry Co., Ltd., trade name "NEX110-18E"), and test pieces [100mm×100mm×thickness 2mm (for abrasion test), 120mm×10mm×thickness 4mm ( Demesia flex test)].

Embodiment 2

[0111] Except having changed the raw material resin into 100 weight part of TPU-2 and 10 weight part of MAH-EPDM, it carried out similarly to Example 1, and produced the pellet and the test piece.

Embodiment 3

[0115] Except having changed the raw material resin into 100 weight part of TPU-3, and 5 weight part of MAH-EPDM, it carried out similarly to Example 1, and produced the pellet and the test piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com