Method and system for controlling liquid crystal diffusion velocity and cell pressing device

A diffusion speed and liquid crystal technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems affecting the viscosity coefficient of liquid crystal, slow diffusion speed, and the influence of liquid crystal panel qualification rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

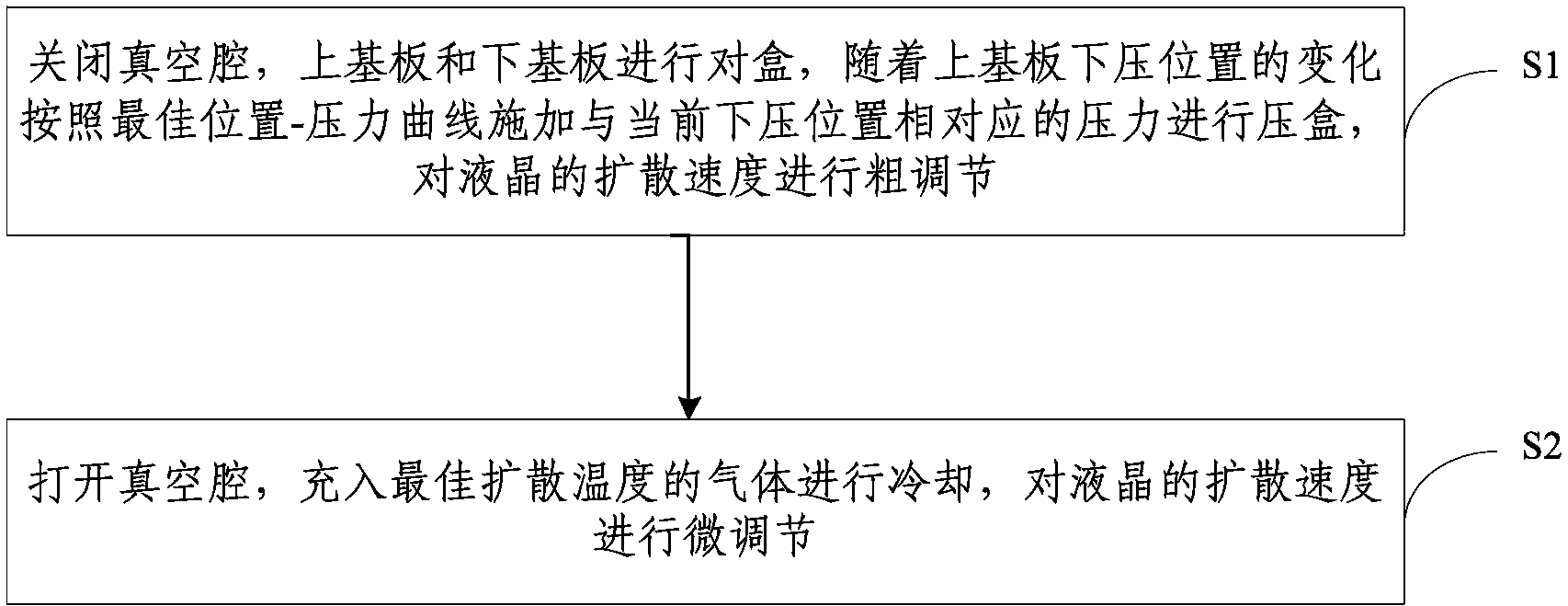

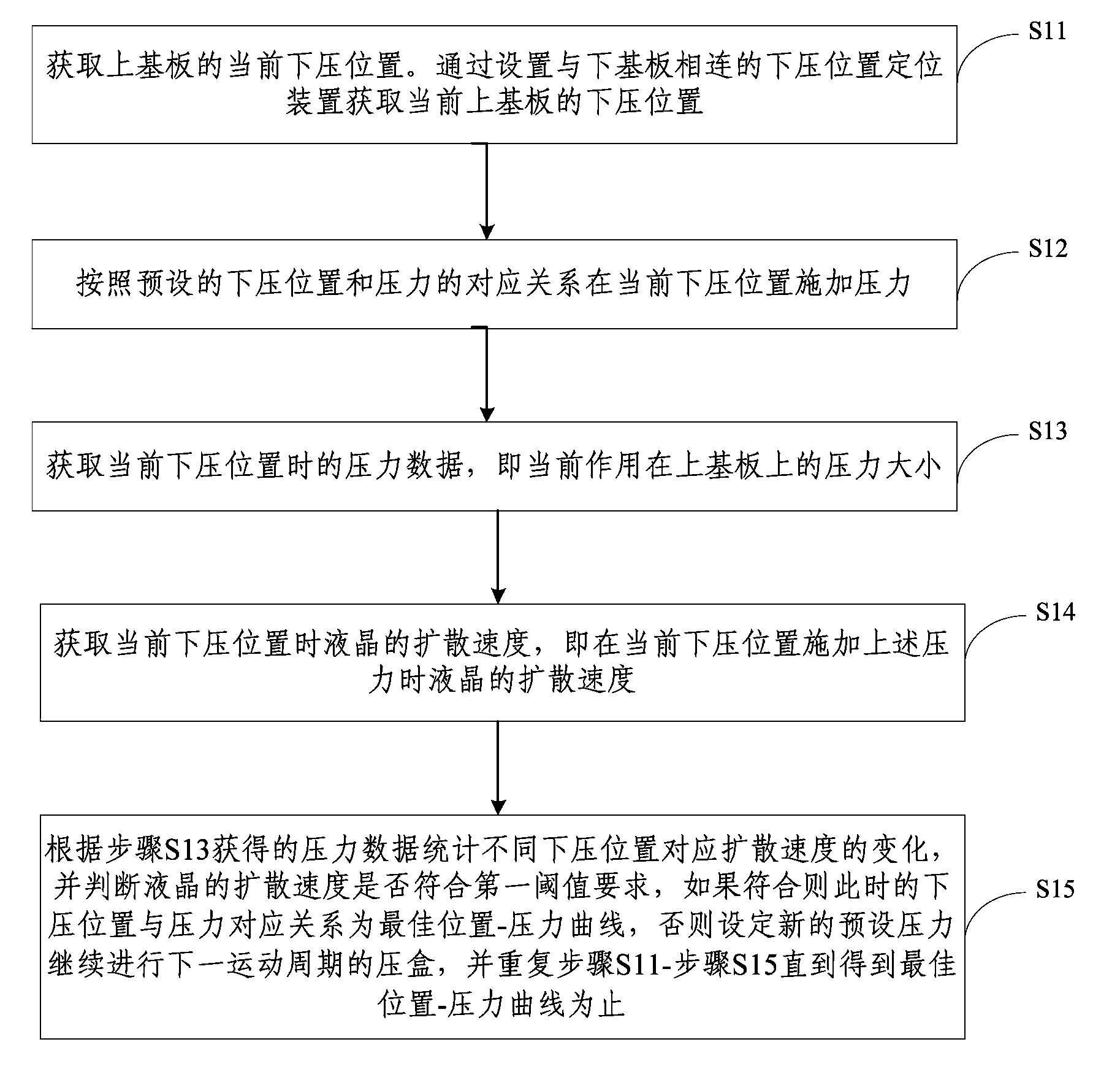

[0048] The embodiment of the present invention provides a method for controlling the diffusion speed of liquid crystal, and the steps are as follows: figure 1 As shown, it specifically includes the following steps:

[0049] Step S1. The vacuum chamber is closed, and the upper substrate and the lower substrate are aligned. As the pressing position of the upper substrate changes, a pressure corresponding to the current pressing position is applied according to the optimal position-pressure curve to press the cell to diffuse the liquid crystal. The speed is adjusted roughly.

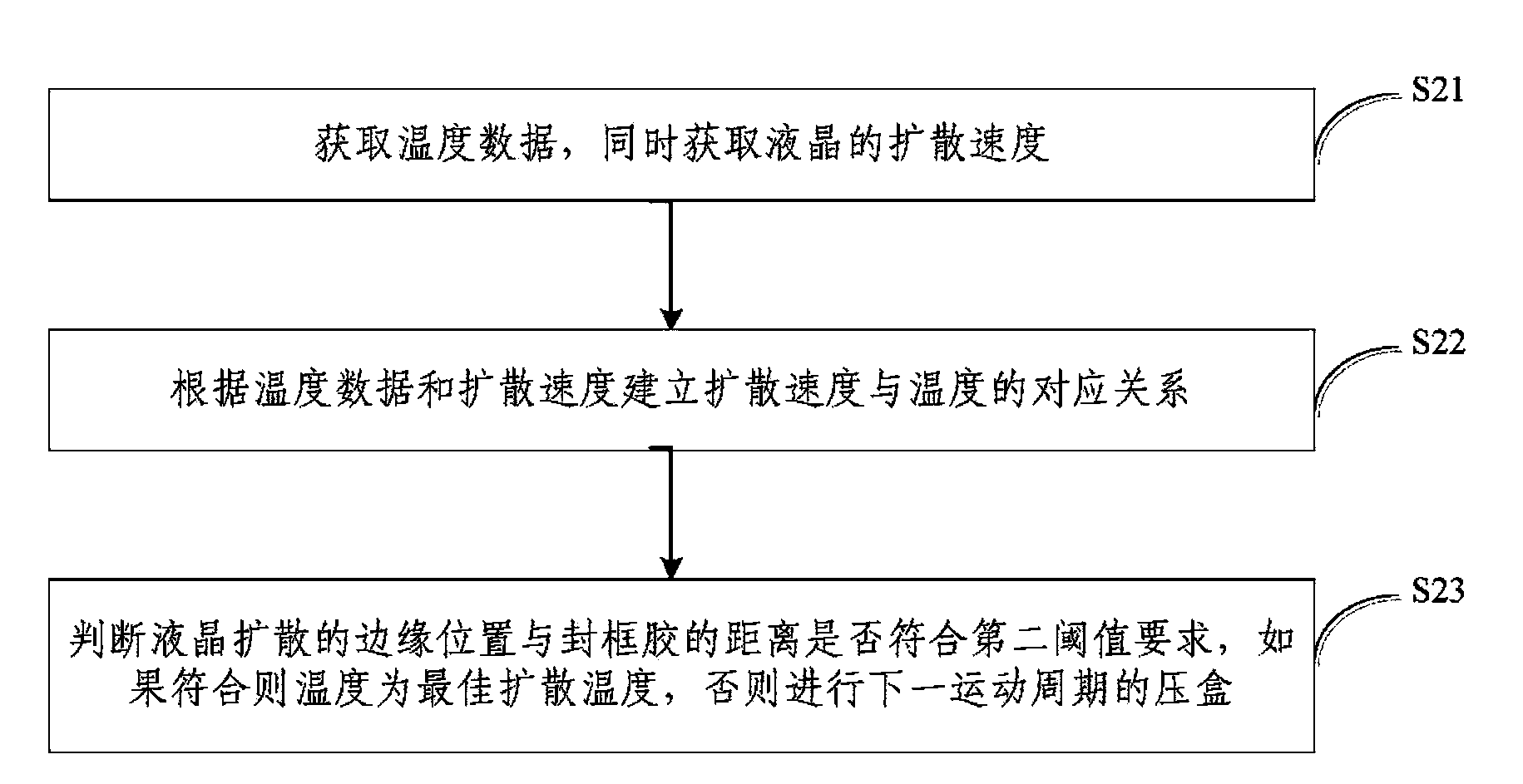

[0050] Step S2: Fill the vacuum chamber with gas with the best diffusion temperature for cooling, and finely adjust the diffusion speed of the liquid crystal.

[0051] The above method of controlling the diffusion speed of liquid crystal is to perform cell alignment when the vacuum chamber is closed. During cell alignment, the pressure is adjusted according to the pressing position of the upper substrate to contro...

Embodiment 2

[0070] In the second embodiment of the present invention, a system for controlling the diffusion speed of liquid crystal is provided. Figure 4 As shown, it includes: a main control device 10, a pressure sensing device 20, and a temperature sensing device 30. The main control device 10 roughly adjusts the diffusion speed of the liquid crystal according to the pressure data obtained by the pressure sensing device 20, and according to the temperature obtained by the temperature sensing device 30 The data fine-tune the diffusion speed of the liquid crystal.

[0071] The main control device 10 in this embodiment is a computer for industrial control, that is, a PLC (Programmable Logic Controller), which receives, processes and processes data collected by the pressure sensing device 20 and the temperature sensing device 30. The pressure sensing device 20 and the temperature sensing device 30 are controlled according to the processing result.

[0072] Further, the pressure sensing device ...

Embodiment 3

[0081] The third embodiment of the present invention provides a box pressing device, the structure diagram is as Figure 7 As shown, it includes an upper platform 01 and a lower platform 02. The upper platform 01 is used to fix the upper substrate, and the lower platform 02 is used to fix the lower substrate. It further includes: pressure sensing equipment, temperature sensing equipment 04, and sensing control equipment And gas pipeline 05, the pressure sensing device is used to sense the pressure of pressing the upper substrate during the pressing process, the temperature sensing device 04 is used to sense temperature changes during the pressing process, and the sensing control device is used to sense the pressure according to the pressure The acquired pressure data roughly adjusts the diffusion speed of the liquid crystal, and finely adjusts the diffusion speed of the liquid crystal according to the temperature data acquired by the temperature sensing device; the gas pipeline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com