A kind of self-flow drying agent and its preparation method and application

A self-flowing, desiccating agent technology, applied in the direction of botany equipment and methods, applications, insecticides, etc., can solve the problems of poor control effect, poor environmental compatibility, damage to wood, etc., to solve xylem vessel embolism , low cost, and enhance the effect of tree vigor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

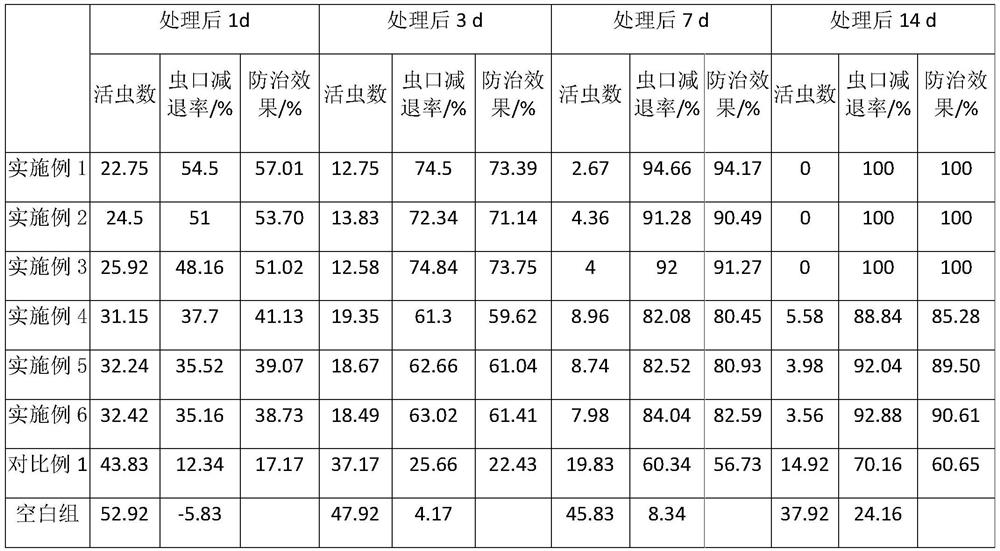

Embodiment 1

[0036] An embodiment of the present invention provides a self-flowing drying agent, which comprises the following components by weight percentage: thickener: 18%, synergist: 3%, fertilizer: 2%, solvent: 10%, surfactant : 20%, insecticide: 6%, antifreeze: 2%, the balance is water;

[0037] Above-mentioned insecticide is that mass ratio is 1:8 thiamethoxam and methylamino abamectin benzoate; Above-mentioned thickener is polyacrylamide; Above-mentioned surfactant is the polyoxyethylene that mass ratio is 1:1 The mixture of octylphenol ether and polyoxyethylene castor oil; the above-mentioned fertilizer is agricultural amino acid; the above-mentioned synergist is sodium nitrophenolate; the above-mentioned solvent is dimethyl sulfoxide; the above-mentioned antifreeze agent is ethylene glycol.

[0038] The preparation method of above-mentioned self-flowing drying agent comprises the following steps:

[0039] Step a, take by weighing each component according to above-mentioned raw m...

Embodiment 2

[0044] An embodiment of the present invention provides a self-flowing drying agent, which comprises the following components by weight percentage: thickener: 0.3%, synergist: 1%, fertilizer: 8%, solvent: 3.7%, surfactant : 5%, insecticide: 2%, antifreeze: 3%, and the balance is water; the insecticides are thiamethoxam and methylaminoavermectin benzoate.

[0045] Above-mentioned insecticide is that mass ratio is 1:10 thiamethoxam and methylamino abamectin benzoate; Above-mentioned thickener is that mass ratio is the mixture of 2:1 polyacrylamide and polyethylene glycol; above-mentioned Surfactant is the mixture of fatty alcohol polyoxyethylene ether and polyoxyethylene castor oil that mass ratio is 1:2; Above-mentioned fertilizer is agricultural amino acid; Above-mentioned synergist is sodium nitrophenolate; Above-mentioned solvent is that mass ratio is 3: 1 of the mixture of dimethyl methanol and octanol; the above-mentioned antifreeze is ethylene glycol.

[0046] The prepara...

Embodiment 3

[0048] An embodiment of the present invention provides a self-flow drying agent, which comprises the following components by weight percentage: thickener: 8%, synergist: 5%, fertilizer: 0.1%, solvent: 19%, surfactant : 38%, insecticide: 4%, antifreeze: 0.2%, and the balance is water; the insecticides are thiamethoxam and methylaminoavermectin benzoate.

[0049]Above-mentioned insecticide is that mass ratio is 1:6 thiamethoxam and methylamino abamectin benzoate; Above-mentioned thickener is polyethylene glycol; Above-mentioned surfactant is that mass ratio is 1:2:1 The mixture of polyoxyethylene octyl phenol ether, fatty alcohol polyoxyethylene ether and polyoxyethylene castor oil; Above-mentioned fertilizer is agricultural amino acid; Above-mentioned synergist is sodium nitrophenolate; Above-mentioned solvent is the dinitrophenolate that mass ratio is 1:1. A mixture of methyl sulfoxide and octanol; the above antifreeze is ethylene glycol.

[0050] The preparation method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com