Concrete faced rockfill dam water stop mortar bed construction trolley

A technology of face rockfill dams and construction trolleys, which is applied in water conservancy projects, sea area projects, infrastructure projects, etc., and can solve the quality requirements that are difficult to meet the flatness of mortar cushions, hidden dangers in the quality of copper waterstops, speed and The size of the cutting material is not easy to control and other problems, so as to achieve the effect of practical, safe and reliable structure, reduce construction safety risk, and simplify the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

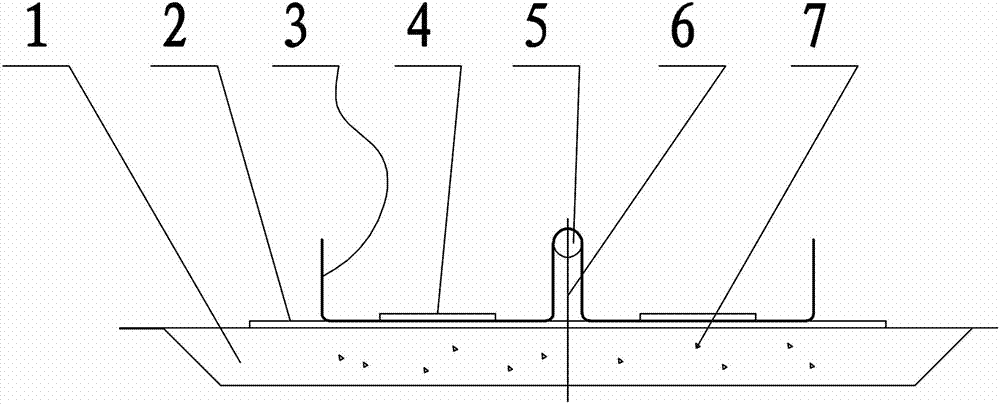

[0026] Such as figure 1 Among them, the overall structure of the mortar cushion layer 7 and the copper water-stop sheet 3 located at the joint of the dam body is as follows: a mortar cushion layer 7 is provided in the mortar cushion layer groove 1, a PVC gasket 2 is arranged on the mortar cushion layer 7, PVC The gasket 2 is provided with a copper waterstop 3, the copper waterstop 3 is provided with a composite waterstop 4, and a rubber rod 5 is provided at the bend of the nose of the copper waterstop 3, and the nose of the copper waterstop 3 The inside is also filled with polyurethane foam filler 6. The installation quality of the copper water stop 3 is closely related to the quality of the mortar cushion 7.

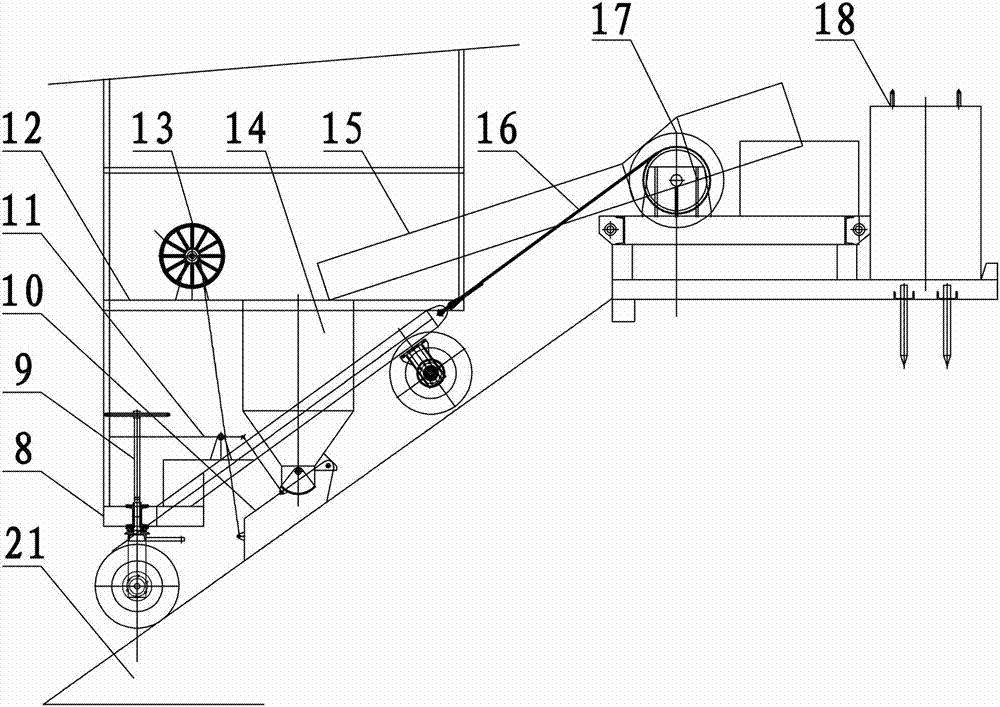

[0027] Such as figure 2 Among them, a construction trolley for the water-stop mortar cushion of a face rockfill dam includes a vehicle frame 8, which is connected to an electric winch 17 installed on the dam crest through a traction wire rope 16, and the center line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com