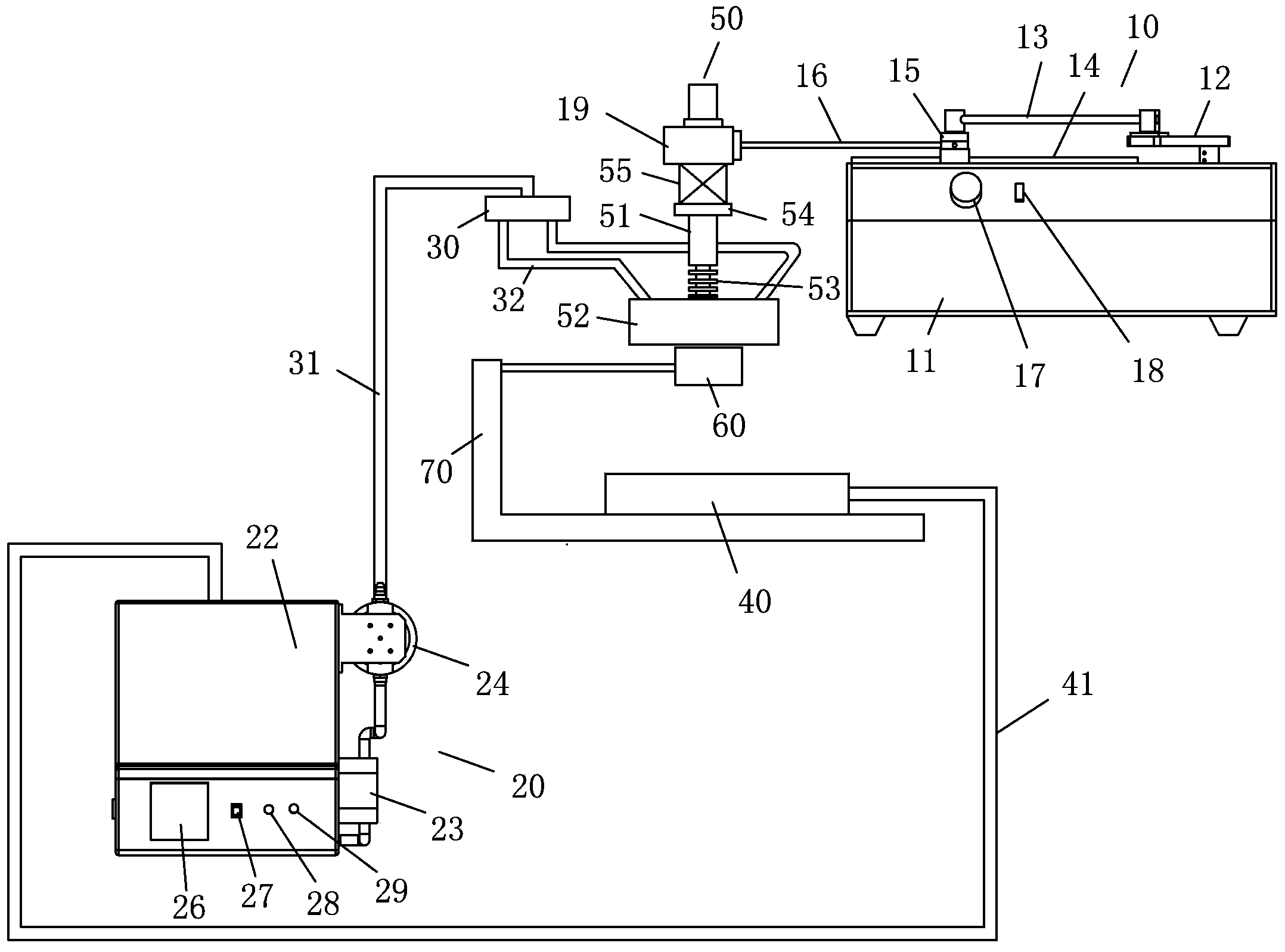

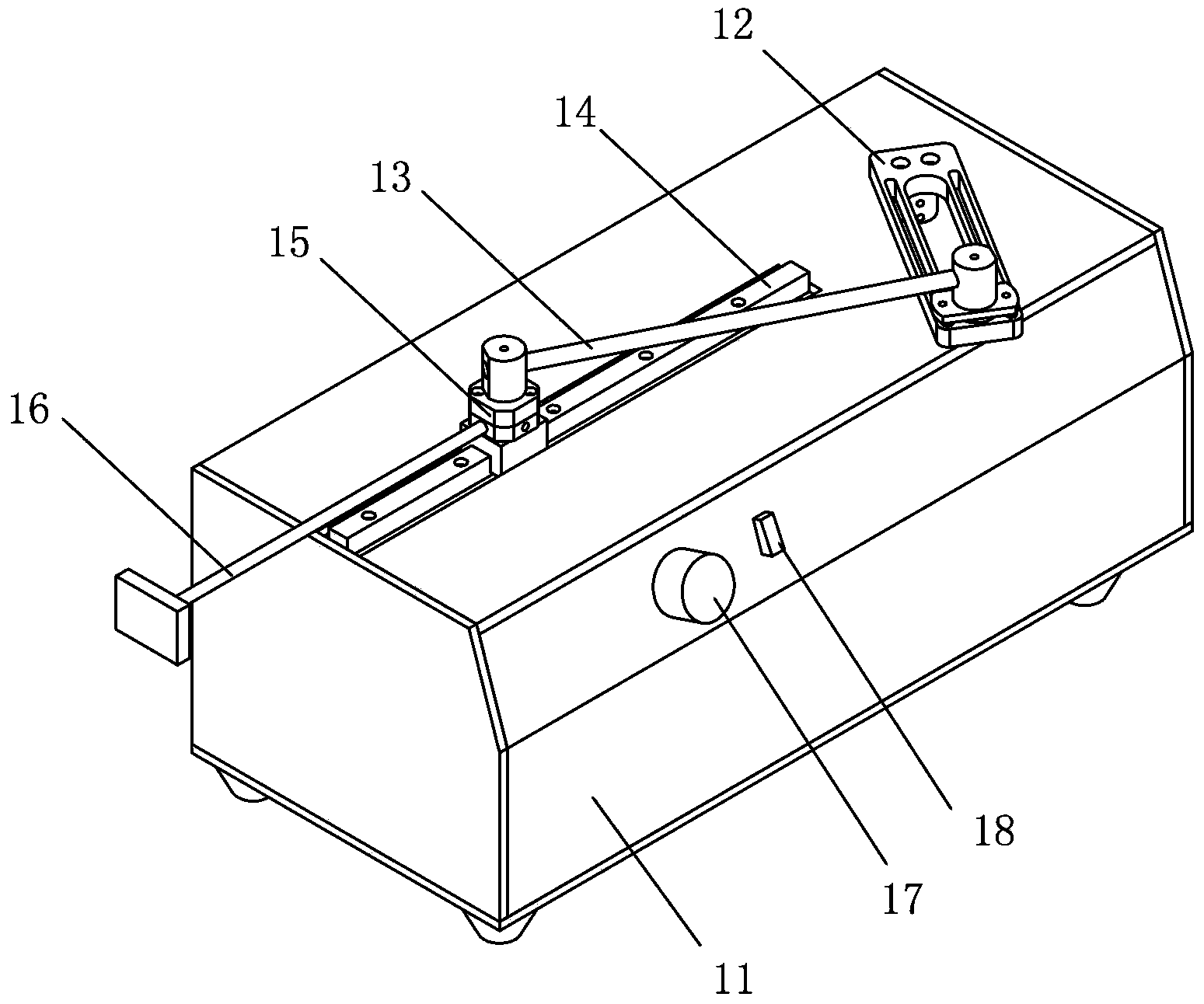

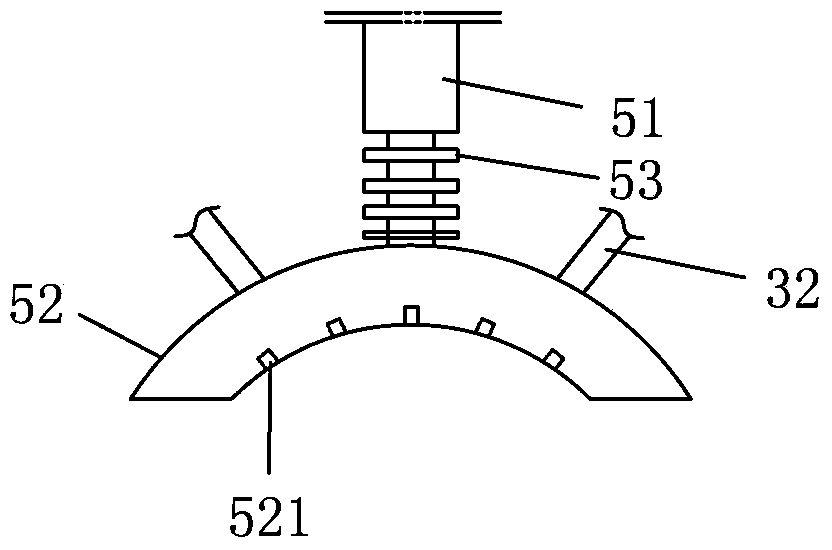

Brush plating device and method for repairing scratches of mechanical parts

A brush plating technology for mechanical parts, applied in the field of brush plating devices, can solve the problems of low quality, low work efficiency, high labor intensity, etc., and achieve strong compactness, good wear resistance and corrosion resistance, The effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056]Take 260g of nickel sulfate, 100g of cobalt sulfate, 15ml of formic acid, 50g of acetic acid, and 20g of hydrochloric acid, dissolve them in distilled water, then add 20g of alumina nanoparticles, disperse them by high-energy mechanochemical method, and dilute to 1L with distilled water.

Embodiment 2

[0058] Take 300g of nickel sulfate, 100g of cobalt sulfate, 20ml of formic acid, 45g of acetic acid, and 10g of hydrochloric acid, dissolve them in distilled water, then add 30g of alumina nanoparticles, disperse them by high-energy mechanochemical method, and dilute to 1L with distilled water.

Embodiment 3

[0060] Take 280g of nickel sulfate, 110g of cobalt sulfate, 15ml of formic acid, 45g of acetic acid, and 15g of hydrochloric acid, dissolve them in distilled water, then add 20g of alumina nanoparticles, disperse them by high-energy mechanochemical method, and dilute to 1L with distilled water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com