Bacillus cereus and probiotics powder thereof as well as preparation and application of probiotics powder

A Bacillus cereus and probiotic technology, applied in the field of microorganisms, can solve the problems of increased fermentation cost, lack of bacterial cells, limitations, etc., and achieve the effects of good safety, probiotics, good acid resistance, and good bacteriostatic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A bacillus cereus probiotic powder, its specific preparation steps are:

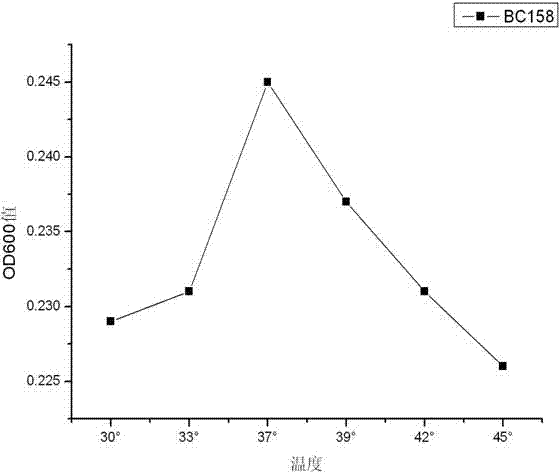

[0047] Step 1, slant solid culture: Bacillus cereus ( Bacillus cereus ) BC158 was inoculated on the solid slant medium, and cultured at 37°C for 24 hours to obtain the strains cultured on the slant solid, and set aside;

[0048] The composition of the solid slant medium is: by mass percentage, the solid slant medium contains 0.3% beef extract, 1% peptone, 0.5% sodium chloride, 1.5% agar powder, and the balance is water;

[0049] Step 2, primary seed culture: take 1 inoculation loop and inoculate the slanted solid cultured bacteria prepared in step 1 into a 500mL Erlenmeyer flask filled with 80 primary seed medium, and then culture it on a shaker at 34°C and 220rpm for 10h to obtain First-grade seed liquid, spare;

[0050] The composition of the primary seed medium is as follows: by mass percentage, the primary seed medium contains 0.3% yeast extract, 0.5% peptone, 0.5% sucrose, 0.3% disodium hyd...

Embodiment 2

[0059] A bacillus cereus probiotic powder, its specific preparation steps are:

[0060] Step 1, slant solid culture: Bacillus cereus ( Bacillus cereus ) BC158 was inoculated on the solid slant medium, and cultured at 37°C for 24 hours to obtain the strains cultured on the slant solid, and set aside;

[0061] The composition of the solid slant medium is: by mass percentage, the solid slant medium contains 0.4% beef extract, 1.2% peptone, 0.5% sodium chloride, 2% agar powder, and the balance is water;

[0062] Step 2, primary seed culture: take the slant solid cultured bacteria prepared in step 1 of the 3-inoculation loop and inoculate it into a 500mL Erlenmeyer flask containing 120mL primary seed medium, and then culture it on a shaker at 37°C and 250rpm for 16h to obtain First-grade seed liquid, spare;

[0063] The composition of the primary seed medium is as follows: by mass percentage, the primary seed medium contains 0.5% yeast extract, 0.7% peptone, 1.0% sucrose, 0.6% diso...

Embodiment 3

[0072] A bacillus cereus probiotic powder, its specific preparation steps are:

[0073] Step 1, slant solid culture: Bacillus cereus ( Bacillus cereus ) BC158 was inoculated on the solid slant medium, and cultured at 37°C for 24 hours to obtain the strains cultured on the slant solid, and set aside;

[0074] The composition of the solid slant medium is: by mass percentage, the solid slant medium contains 0.35% beef extract, 1.1% peptone, 0.5% sodium chloride, 1.8% agar powder, and the balance is water;

[0075] Step 2, primary seed culture: take the slant solid culture strains prepared in step 1 of the 2 inoculation loops and inoculate them into a 500mL Erlenmeyer flask filled with 100mL primary seed medium, and then culture them on a shaker at 36°C and 240rpm for 14h to obtain First-grade seed liquid, spare;

[0076] The composition of the primary seed medium is as follows: by mass percentage, the primary seed medium contains 0.4% yeast extract, 0.6% peptone, 0.8% sucrose, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com