Environment-friendly automatic filling device

An automatic filling and environmental protection technology, applied in packaging, transportation and packaging, packaging types and other directions, can solve the problems of large power consumption and space consumption of conveyor lines, low delivery efficiency, and large human injury, so as to improve delivery efficiency, The effect of high delivery efficiency and enhanced security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

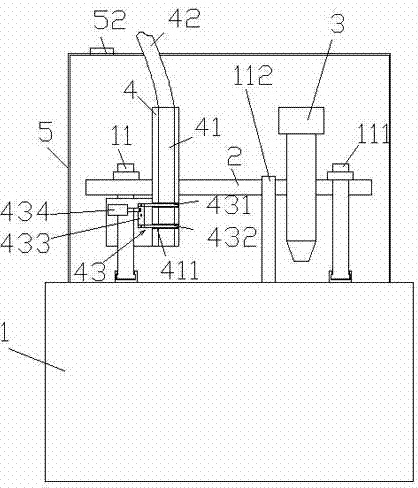

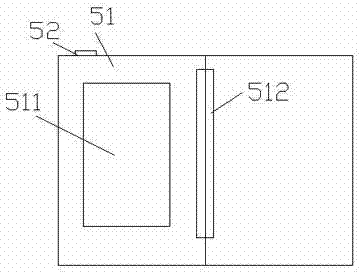

[0026] A kind of environment-friendly automatic filling equipment, see attached figure 1 , 2 ; Including a square platform 1, mounting platform 2, adjusting device 11 is arranged between installing platform 2 and platform 1, adjusting device 11 includes 2 screw rods 111 and two guide rods 112, and installing platform 2 is provided with mounting holes Cooperate with the guide rod 112, the screw rod 111 is screwed on the installation platform 2, and a fixing nut is provided on the screw rod 111 to ensure that the position of the screw rod 111 is fixed after the position is adjusted, and the lower end of the screw rod 111 is provided with a diameter larger than The connecting rod of the screw rod 111 is rotatably installed on the connecting seat of the platform 1. It is restricted by the connecting seat and cannot move up and down. In order to facilitate adjustment, the specification of the fixing nut is M22X0.8; there are two more on the mounting platform 2 The device placement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com