Carbon-carbon composite guide rail and preparation method thereof

A carbon composite material and guide rail technology, applied in metal material coating process, gaseous chemical plating, wheel type, etc., can solve problems such as safety and hidden dangers, eliminate rivet breakage, avoid corrosion, and improve size and distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

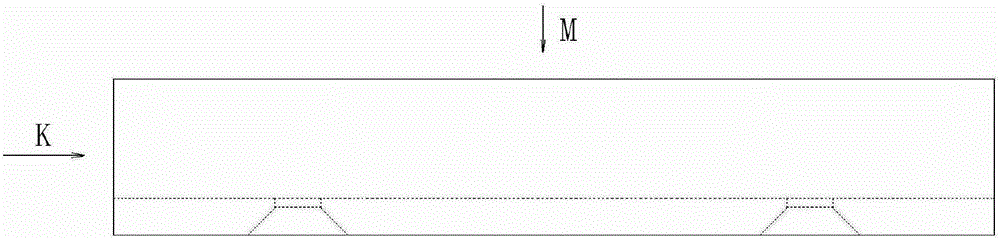

[0039]This embodiment is a guide rail for an aircraft hub. The cross-section of the guide rail is U-shaped or straight-grooved V-shaped or flat-bottomed V-shaped, so that the described guide rail can cooperate with the guide rail platform of the wheel hub.

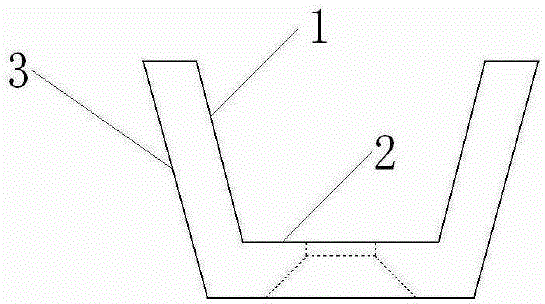

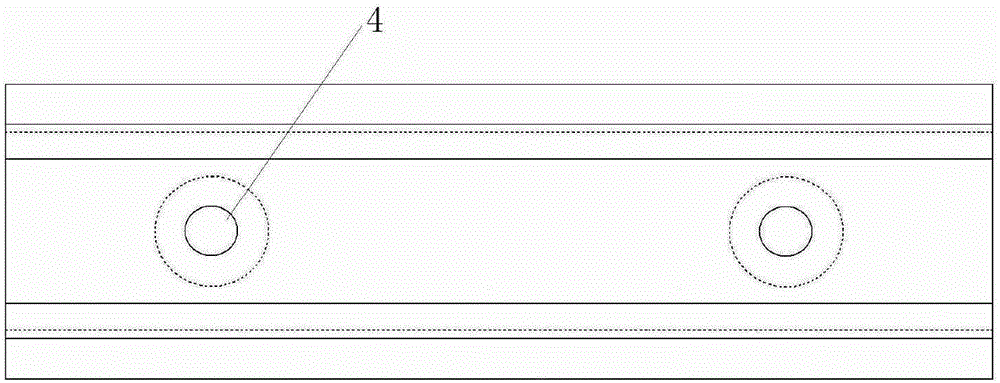

[0040] In this embodiment, the cross section of the guide rail is V-shaped. Made of carbon-carbon composite material. The inner surface 1 and the outer surface 3 on both sides of the guide rail form an angle of 90 to 105° with the bottom surface 2 of the guide rail. The angle between the bottom surfaces 2 is 95°. There are two countersunk holes 4 on the groove bottom surface 2 of the guide rail, and the holes are located on the center line in the length direction of the guide rail. The two counterbores are equidistant from both ends of the guide rail. When assembling, the inner surface 1 and the bottom surface 2 of the guide rail are matched with the hub guide rail platform, and are fastened with screws through the hol...

Embodiment 2

[0058] This embodiment is a guide rail for an aircraft hub. The cross section of the guide rail is U-shaped or straight grooved V-shaped or V.

[0059] In this embodiment, the cross section of the guide rail is U-shaped and made of carbon-carbon composite material. Two countersunk holes 4 are opened on the groove bottom surface 2 of the U-shaped guide rail, and the holes are located on the centerline in the length direction of the guide rail. The two counterbores are equidistant from both ends of the guide rail. When assembling, the inner surface 1 and the bottom surface 2 of the guide rail are matched with the hub guide rail platform, and are fastened with screws through the holes 4. The carbon-carbon composite guide rail is made of polyacrylonitrile-based carbon cloth with a density of 1.70g / cm 3 .

[0060] This embodiment also proposes a method for preparing the above-mentioned guide rail by chemical vapor deposition (CVD), and the specific steps are:

[0061] Step 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com