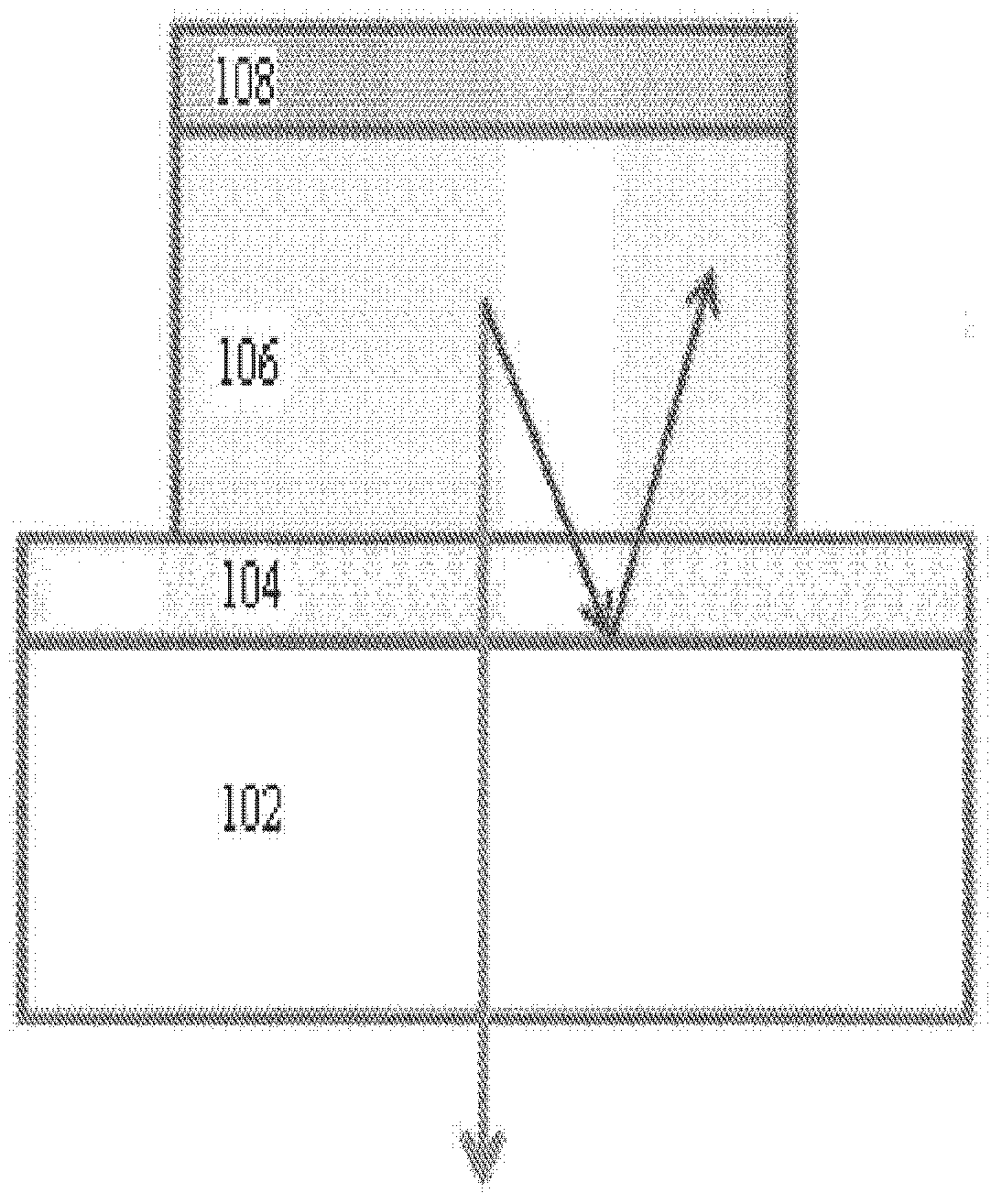

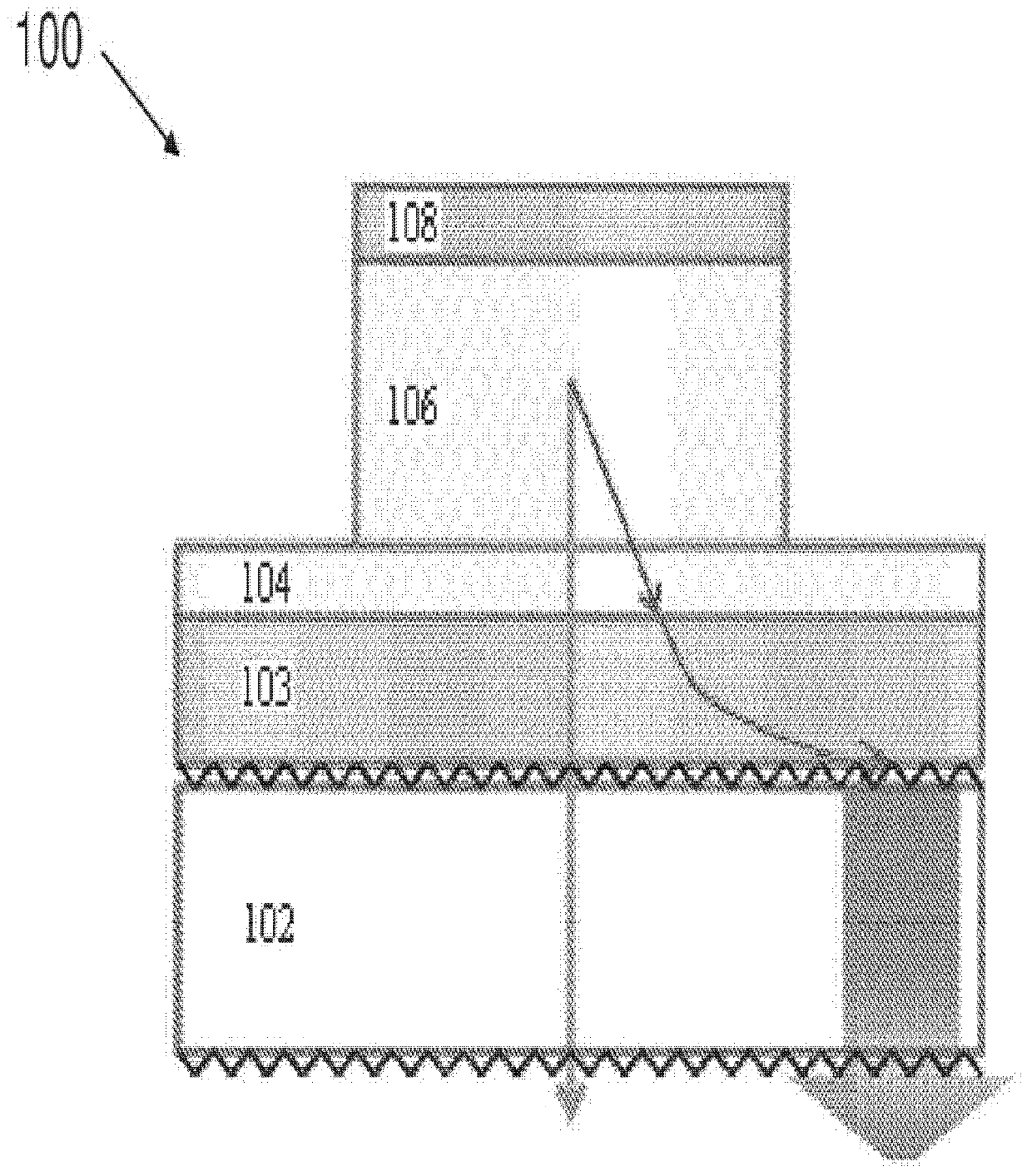

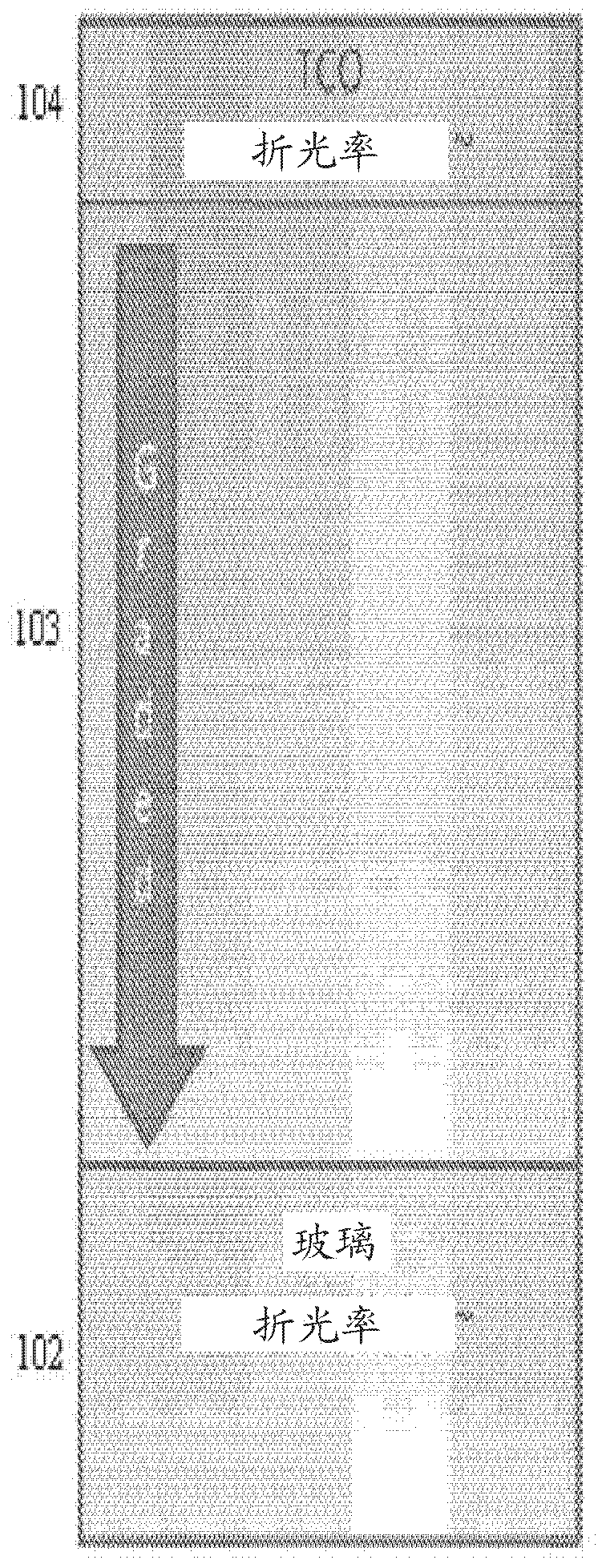

Internal optical extraction layer for OLED devices

A technology of light extraction layer and light-emitting device, which is applied in the manufacture of semiconductor devices, electric solid-state devices, semiconductor/solid-state devices, etc., and can solve the problems of reducing light emission of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Unless otherwise indicated, all experiments were performed in air under ambient conditions.

[0087] TiO 2 Sol-Gel Synthesis

[0088] in TiO 2 In sol-gel synthesis, two types of templates based on ethylene oxide and propylene oxide are used block copolymers. Will F127 block copolymer (755mg, 0.06mmol) or P123 block copolymers (690 mg, 0.12 mmol or 345 mg, 0.06 mmol, each bifunctional block copolymer terminated with a primary hydroxyl group) were dissolved in 7.41 ml of n-butanol. The P123 block copolymer (at both concentrations) dissolved completely, but The F127 block copolymer produced a slightly opaque colloidal solution. Separately, 1.33 ml (16.1 mmol concentration) of HCl was slowly added under vigorous stirring to 1.93 ml (9.2 mmol) of tetraethoxytitanium, Ti(OEt) 4 in order to moderate any temperature increase from this exothermic reaction. Then in the process of 2-3 minutes at room temperature, the corresponding polymer solution was slowly pipetted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com