Positive pole material LiFePO4 for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in the field of lithium-ion battery positive electrode materials and their preparation, can solve problems such as complex process operation steps, irreversible capacity loss, and difficult industrialization, so as to achieve high production efficiency and accelerate lithium storage power The effect of learning and crystallization quality is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

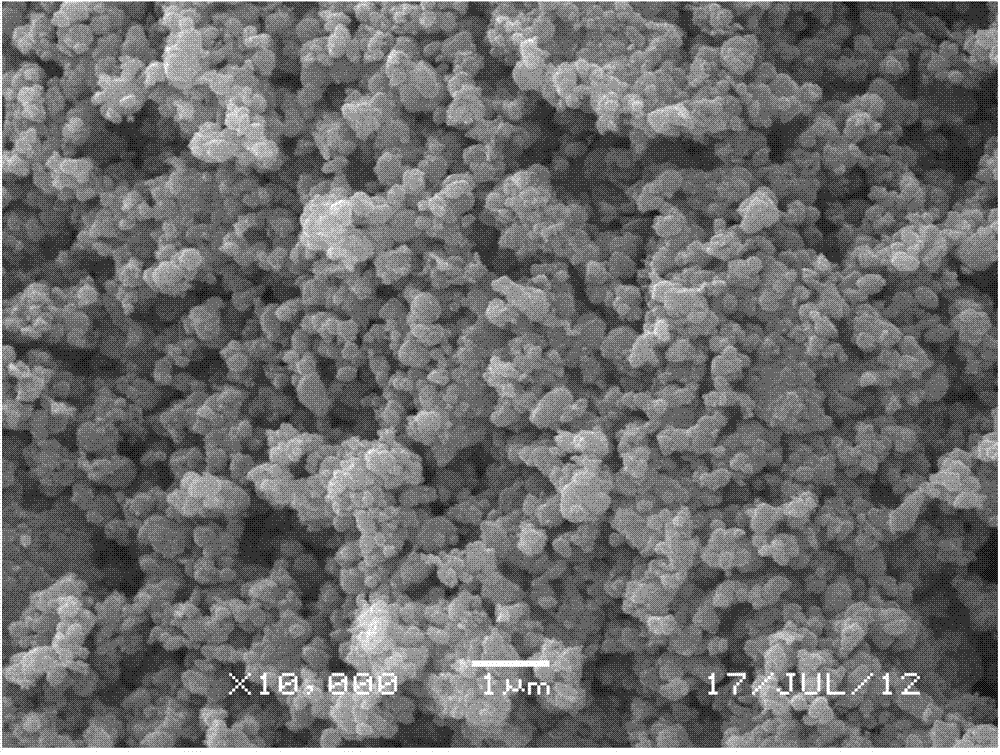

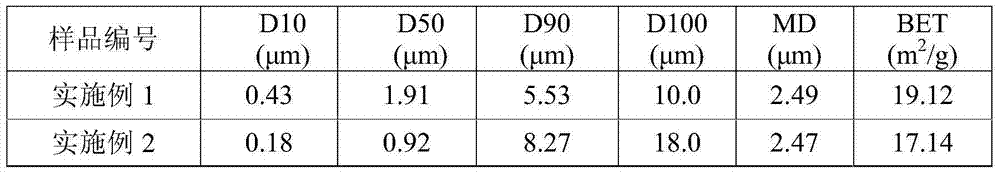

[0035] a kind of like figure 1 Lithium-ion battery cathode material LiFePO shown in the present invention 4 , the lithium-ion battery cathode material LiFePO 4 the D 50 At 1.91μm, specific surface area at 19.12m 2 / g, tap density 1.55g / cm 3 .

[0036] Lithium-ion battery cathode material LiFePO of the present embodiment 4 It is prepared by using ferrous oxalate as the iron source with a nano-ceramic grinding and dispersing machine, and specifically includes the following steps:

[0037] (1) Raw material preparation: prepare as raw materials ferrous oxalate (i.e. iron source), lithium hydroxide, phosphoric acid and compounds containing doped metal elements, the doped metal is Nb; the compound containing doped metal Nb elements refers to niobium oxalate; According to Li 0.95 Nb 0.01 FePO 4 The molecular formula is used for batching; considering the burning loss of the lithium source and the phosphorus source during the sintering process, a small amount of surplus is req...

Embodiment 2

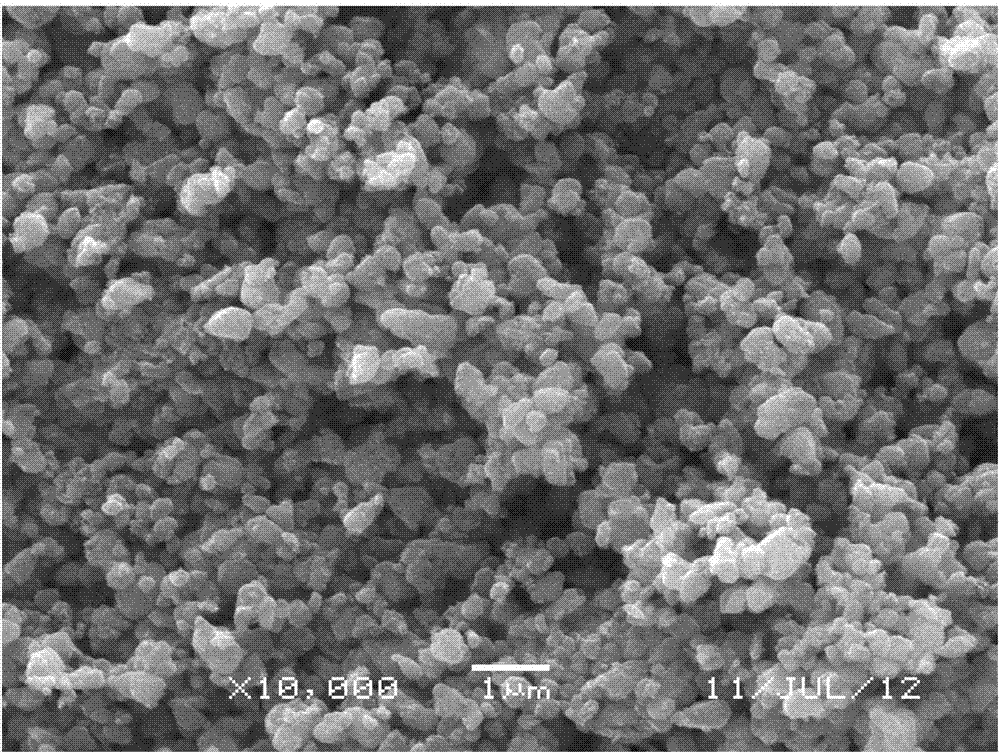

[0044] a kind of like figure 2 Lithium-ion battery cathode material LiFePO shown in the present invention 4 , the lithium-ion battery cathode material LiFePO 4 the D 50 At 0.92μm, specific surface area at 17.14m 2 / g, tap density 1.58g / cm 3 .

[0045] Lithium-ion battery cathode material LiFePO of the present embodiment 4 It is prepared by using ferrous oxalate as the iron source with a nano-ceramic grinding and dispersing machine, and specifically includes the following steps:

[0046] (1) Raw material preparation: Prepare as raw materials ferrous oxalate (i.e. iron source), lithium hydroxide, phosphoric acid and compounds containing doping metal elements. The doping metals are Nb, Mg, Ti, Mn and Zn; containing doping metals The compound of Nb element refers to niobium oxalate; the compound containing doped metal Mg element refers to basic magnesium carbonate; the compound containing doped metal Ti element refers to titanium dioxide; the compound containing doped metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com