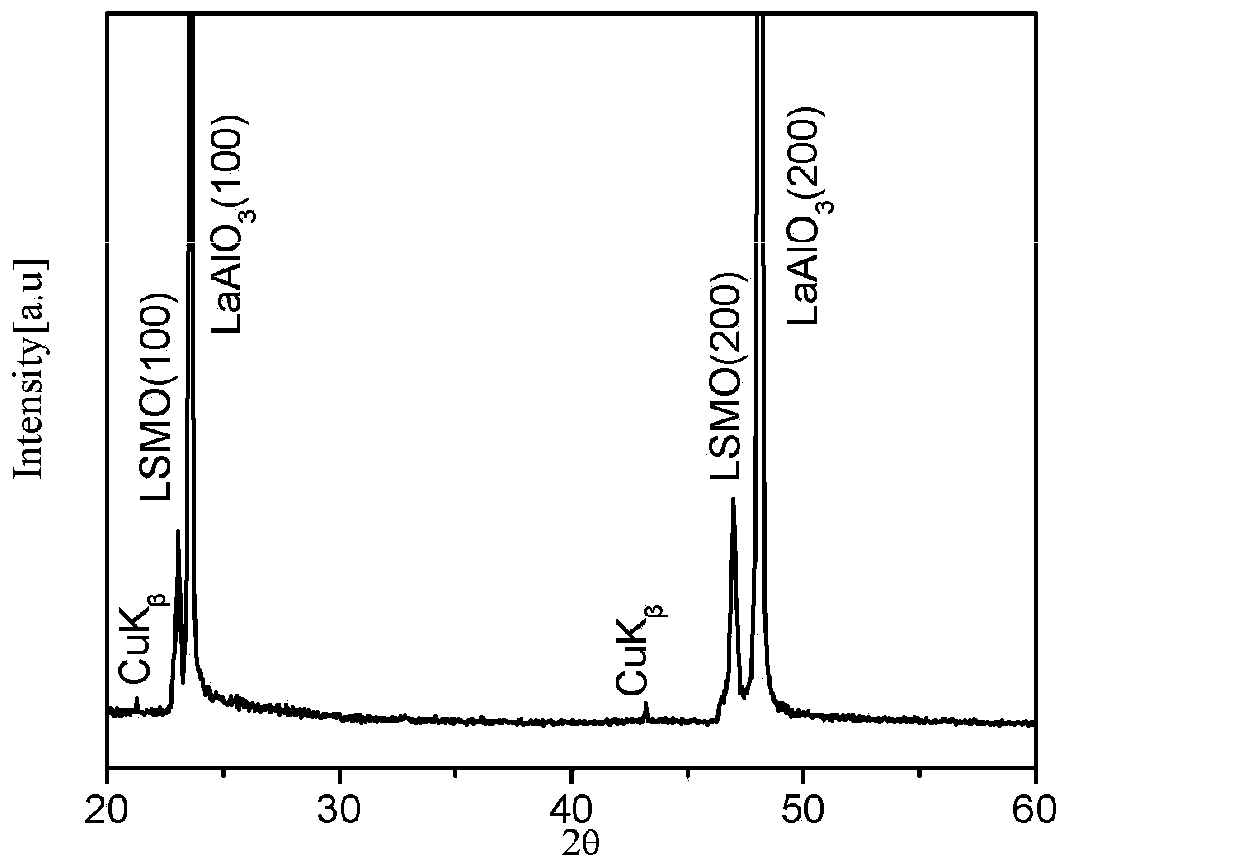

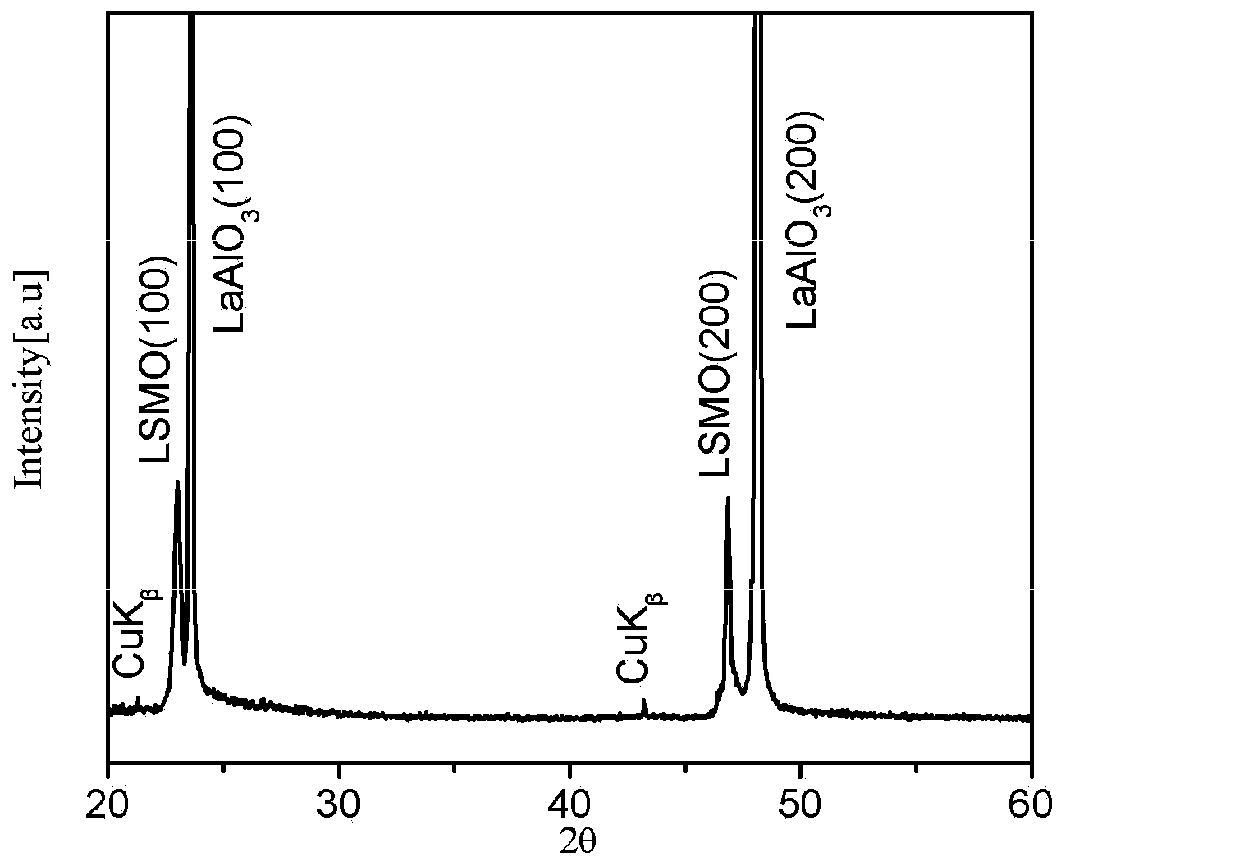

Preparation method of high temperature superconducting coated conductor La0.7Sr0.3MnO3 buffer layer thin film

A technology of coated conductors and high-temperature superconductors, which is applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as strong irritation, expensive metal alkoxides, and high toxicity, so as to increase film formation and avoid Formation of holes and cracks, effect of increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation high temperature superconducting coating conductor La 0.7 Sr 0.3 MnO 3 The method for buffer layer thin film, its step is:

[0036] a. Preparation of anhydrous solution: Dissolve lanthanum nitrate, strontium nitrate and manganese nitrate in N, N-dimethylformamide under ultrasonic conditions with the ratio of lanthanum, strontium and manganese ions being 7:3:10 In, an anhydrous solution is formed; the total concentration of metal ions in the anhydrous solution is 0.1mol / L,

[0037] b. Colloid preparation: Add polyvinylpyrrolidone K30 to the anhydrous solution in step a to form a colloid under ultrasonic conditions; the amount of compound polyvinylpyrrolidone K30 added is 3% of the total mass of the colloid.

[0038] c. Colloid coating and drying: Coat the colloid prepared in step b on the lanthanum aluminate substrate, and then dry it in an infrared drying oven; the specific method of coating the colloid on the substrate is to place the substrate...

Embodiment 2

[0043] A kind of preparation high temperature superconducting coating conductor La 0.7 Sr 0.3 MnO 3 The method for buffer layer thin film, its step is:

[0044] a. Preparation of anhydrous solution: Dissolve lanthanum nitrate, strontium nitrate and manganese nitrate in N, N-dimethylformamide under ultrasonic conditions with the ratio of lanthanum, strontium and manganese ions being 7:3:10 In, an anhydrous solution is formed; the total concentration of metal ions in the anhydrous solution is 0.3mol / L,

[0045] b. Preparation of colloid: Add polyvinylpyrrolidone K30 to the anhydrous solution in step a, and form a colloid under ultrasonic conditions; the amount of compound polyvinylpyrrolidone K30 added is 5% of the total mass of the colloid.

[0046] c. Colloid coating and drying: Coat the colloid prepared in step b on the lanthanum aluminate substrate, and then dry it in an infrared drying oven; the specific method of coating the colloid on the substrate is to place the subs...

Embodiment 3

[0051] A kind of preparation high temperature superconducting coating conductor La 0.7 Sr 0.3 MnO 3 The method for buffer layer thin film, its step is:

[0052] a. Preparation of anhydrous solution: Dissolve lanthanum nitrate, strontium nitrate and manganese nitrate in N, N-dimethylformamide under ultrasonic conditions with the ratio of lanthanum, strontium and manganese ions being 7:3:10 In, an anhydrous solution is formed; the total concentration of metal ions in the anhydrous solution is 0.4mol / L,

[0053] b. Colloid preparation: Add polyvinylpyrrolidone K30 to the anhydrous solution in step a, and form a colloid under ultrasonic conditions; the amount of compound polyvinylpyrrolidone K30 added is 7% of the total mass of the colloid.

[0054] c. Colloid coating and drying: Coat the colloid prepared in step b on the lanthanum aluminate substrate, and then dry it in an infrared drying oven; the specific method of coating the colloid on the substrate is to place the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com