Conductive slurry used for solar cell and method of preparing the same

A solar cell and conductive paste technology, applied in the field of solar cells, can solve the problems of low metal film warpage, large square resistance, and unsatisfactory photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

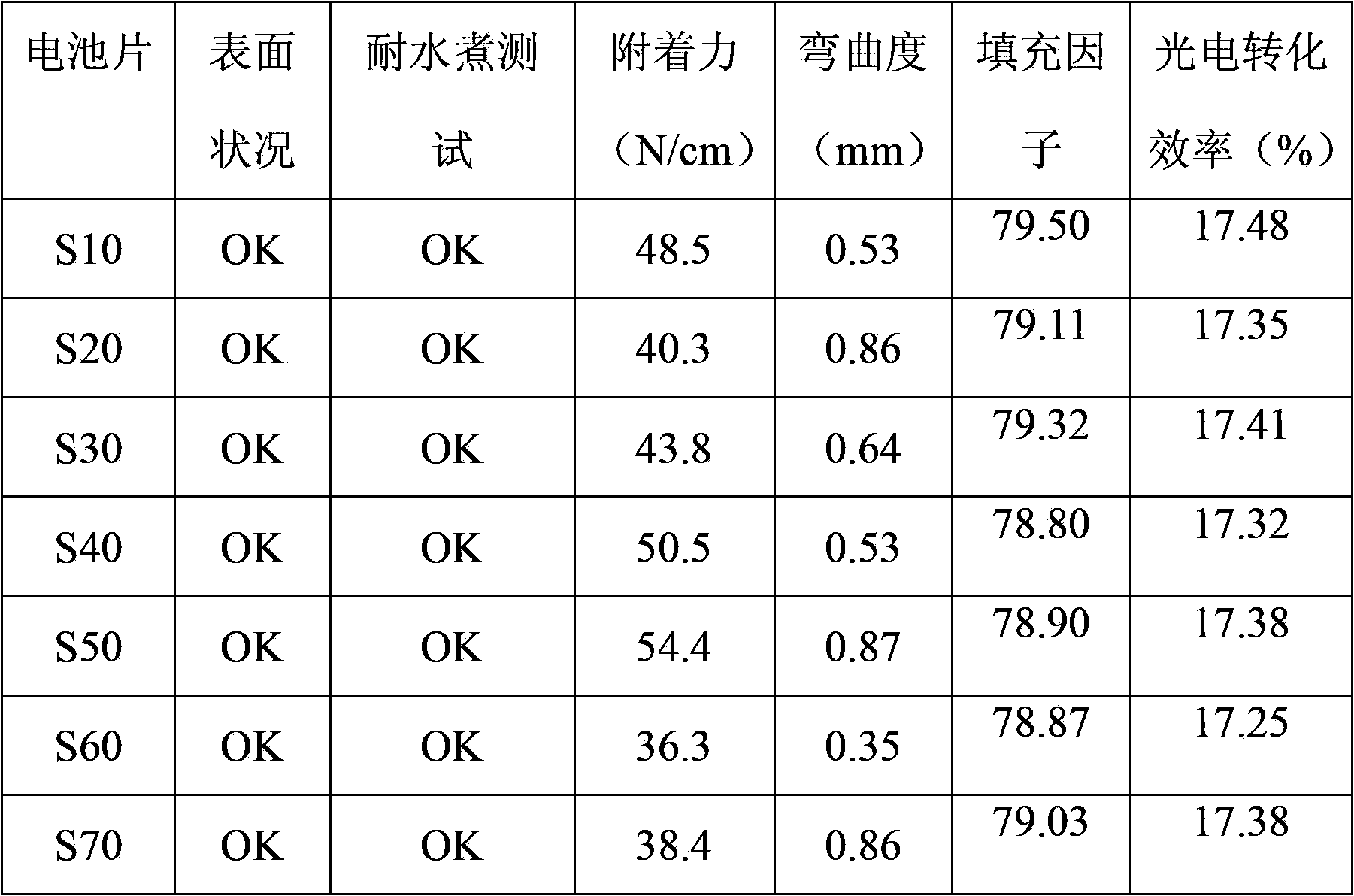

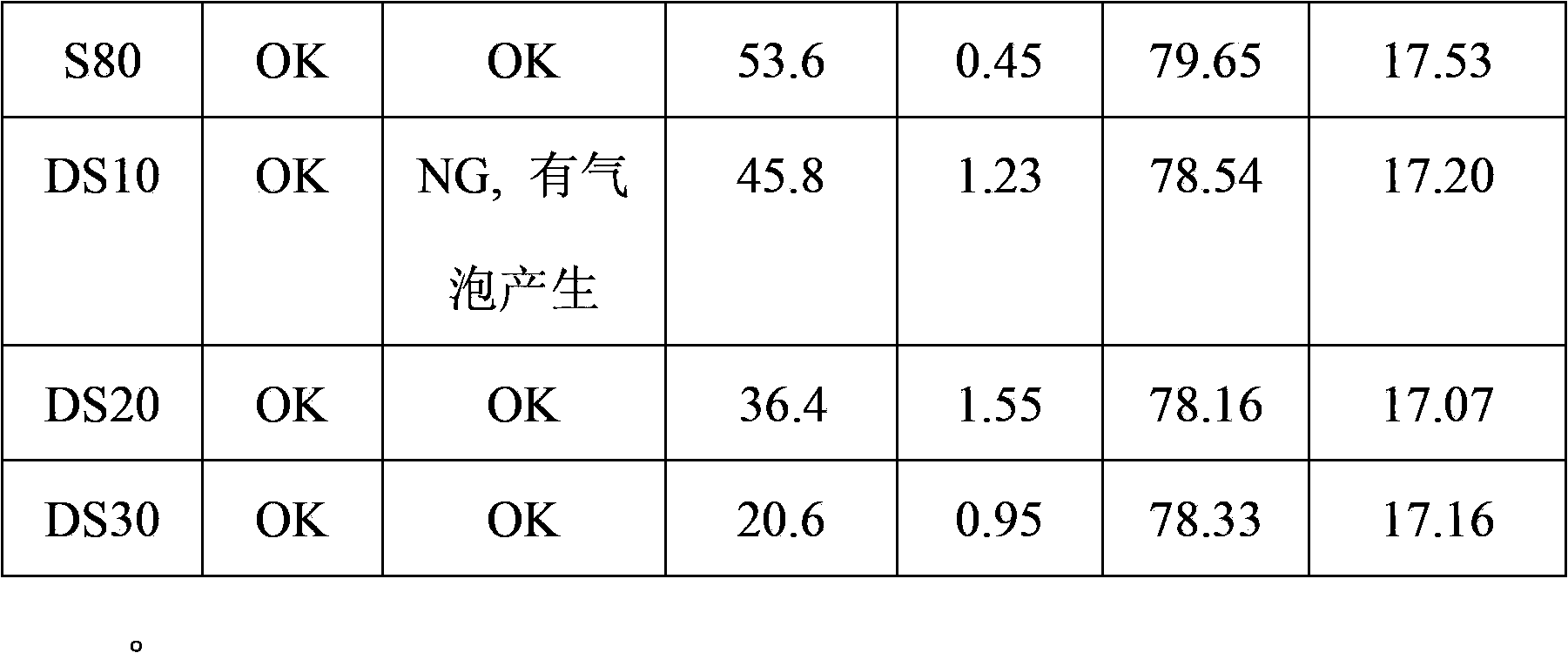

Examples

preparation example Construction

[0020] At the same time, the present invention provides a method for preparing the above-mentioned conductive paste for solar cells. The steps include: dispersing at least two kinds of inorganic glass powder and conductive metal powder in an organic carrier, and grinding to obtain the conductive paste. The method is simple and easy to implement.

[0021] Dispersed in the organic vehicle using various dispersion methods known to those skilled in the art, the conductive metal powder and various glass powders can be added to the organic vehicle for mixing, or all or part of them can be mixed and added to the organic vehicle for mixing. It can be added at one time or in batches. The present invention is not limited. The method of adding and mixing method is not limited in the present invention. When the conductive metal powder is spherical aluminum powder with various particle sizes, it can be specifically Mix the selected glass powders and spherical aluminum powders of various par...

Embodiment 1

[0026] This embodiment is used to prepare aluminum back field conductive paste.

[0027] (1) Preparation of inorganic glass powder

[0028] Take 49wt% Bi 2 o 3 , 25wt% B 2 o 3 , 16wt% SiO 2 , 4wt% Sb 2 o 3 , 2.0wt% BaO, 2.0wt% MgO, 1.0wt% CaO, 1.0wt% Al 2 o 3 , use a V-type mixer to mix evenly, put it into a porcelain crucible, put it into a silicon carbide rod furnace, preheat it to 550°C, keep it warm for 0.5h, then raise it to 1250°C, melt it for 1.0h, and filter it with water to obtain glass Put the beads into the ball milling tank, control the mass ratio, zirconia balls: glass beads: deionized water = 4:1:0.5, tank speed 100 / min, wet ball milling for 7 hours, filter, dry, then dry mill for 2.5 hours, dry When grinding, the mass ratio of zirconia balls to glass beads is 1:2 to obtain inorganic glass powder A11.

[0029] Using a BT-2003 laser particle size distribution analyzer (produced by Liaoning Dandong Baite Company, the same below), using water as the disper...

Embodiment 2

[0037] Aluminum back field conductive paste S2 was prepared by the same method as in Example 1, except that the mass ratio of inorganic glass powder A11 to inorganic glass powder A12 was 1:0.5 to obtain mixed glass powder A2, which was prepared by mixing glass powder A2 Aluminum back field conductive paste S2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Average linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com