In-situ solidification and stabilization treatment system for polluted soil

A technology of stabilization treatment and in-situ solidification, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems such as the inability to quantify the cost of chemicals, insufficient solidification stirring depth, poor stirring uniformity, etc., to improve stirring and solidification. Effect, conducive to smooth sinking, the effect of small movement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

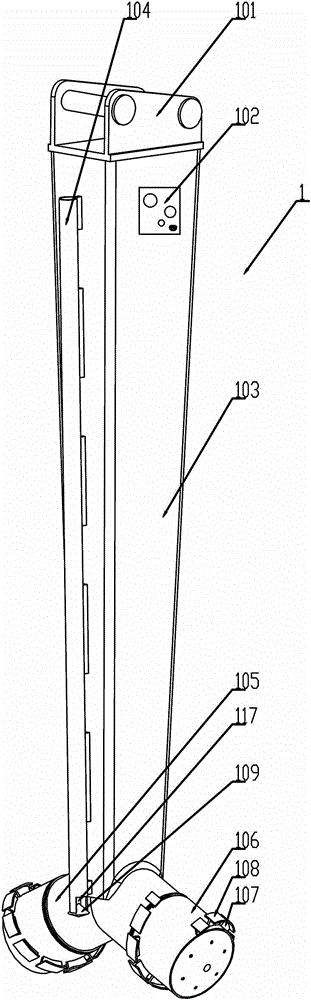

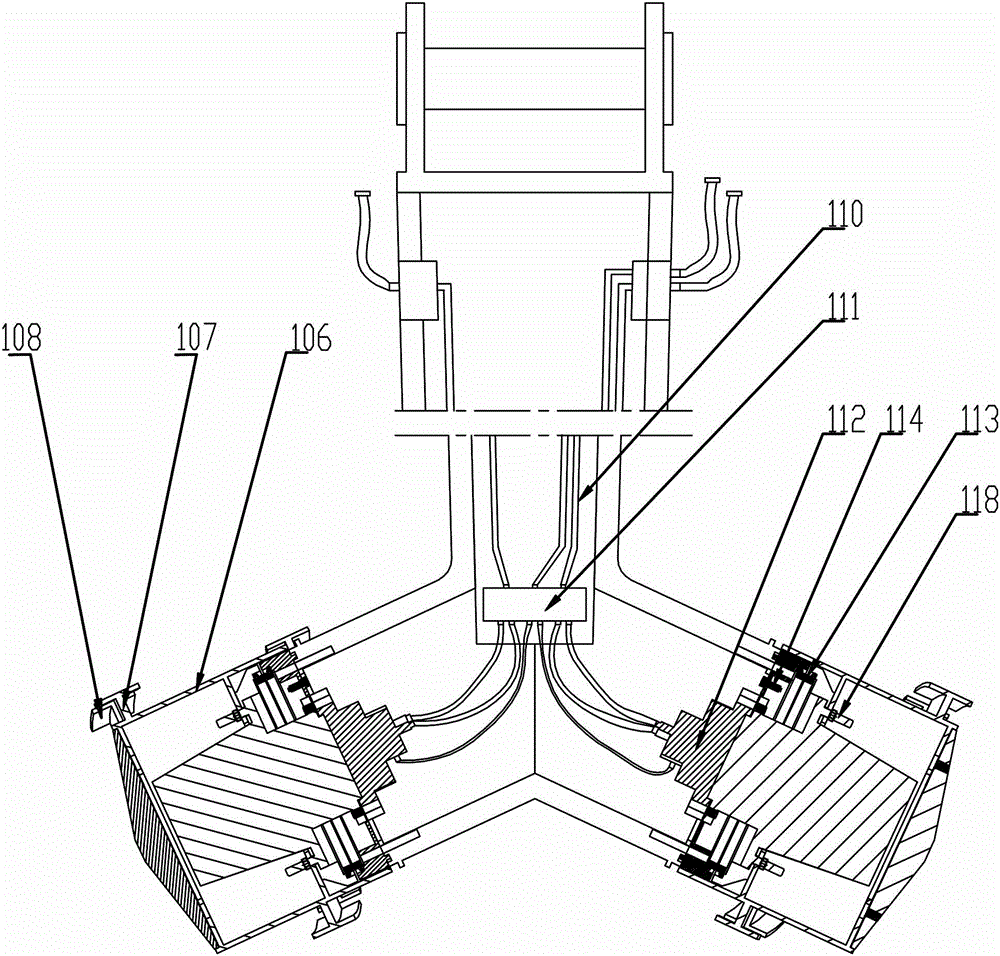

[0029] like figure 2 As shown in , an in-situ solidification and stabilization treatment system for contaminated soil includes a connecting substrate module 101 for connecting a hydraulic excavator 3. The connecting substrate module 101 is arranged on the upper end of the arm structure frame 103 of the homomixing arm 1, and the arm structure The lower end of the frame 103 is symmetrically provided with two fixed cylinders 105 arranged inclined downward. A hydraulic motor 112 is fixed in the fixed cylinder 105. The hydraulic motor 112 is connected with the rotating cylinder 106 through a transmission device. A plurality of stirring blades 108 are provided in a helical arrangement.

[0030] like figure 2 , 3 Among them, the plurality of stirring blade plates 108 are connected with the rotating cylinder 106 through the connecting portion 107, the cross-section of the stirring blade 108 and the connecting portion 107 is in a “T” shape, and the tangent of the outer wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com