Method for production of L-4-hydroxyproline by using recombinant escherichia coli fermentation

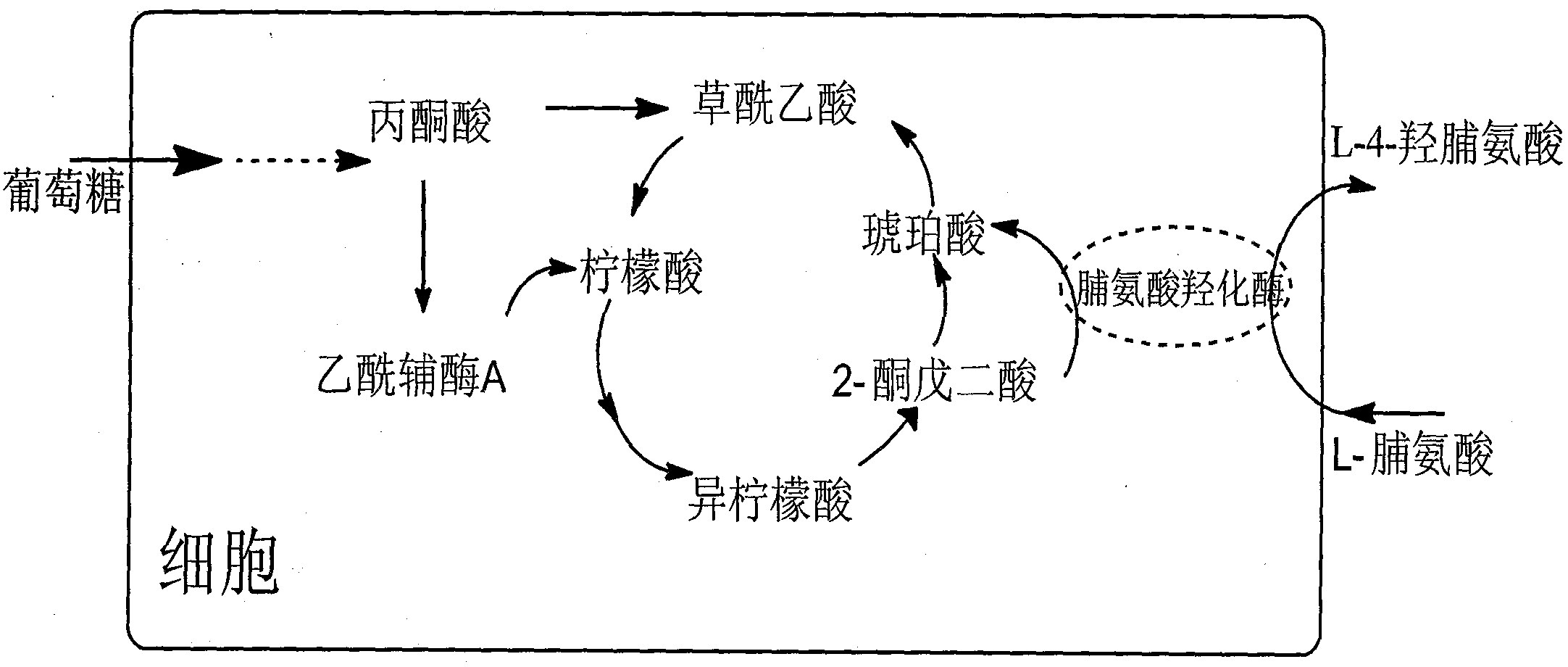

A technology for recombining Escherichia coli and hydroxyproline, applied in the field of microbial genetic engineering, can solve the problems of high cost, low extraction rate, and large pollution of L-4-hydroxyproline, and achieve good industrial development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

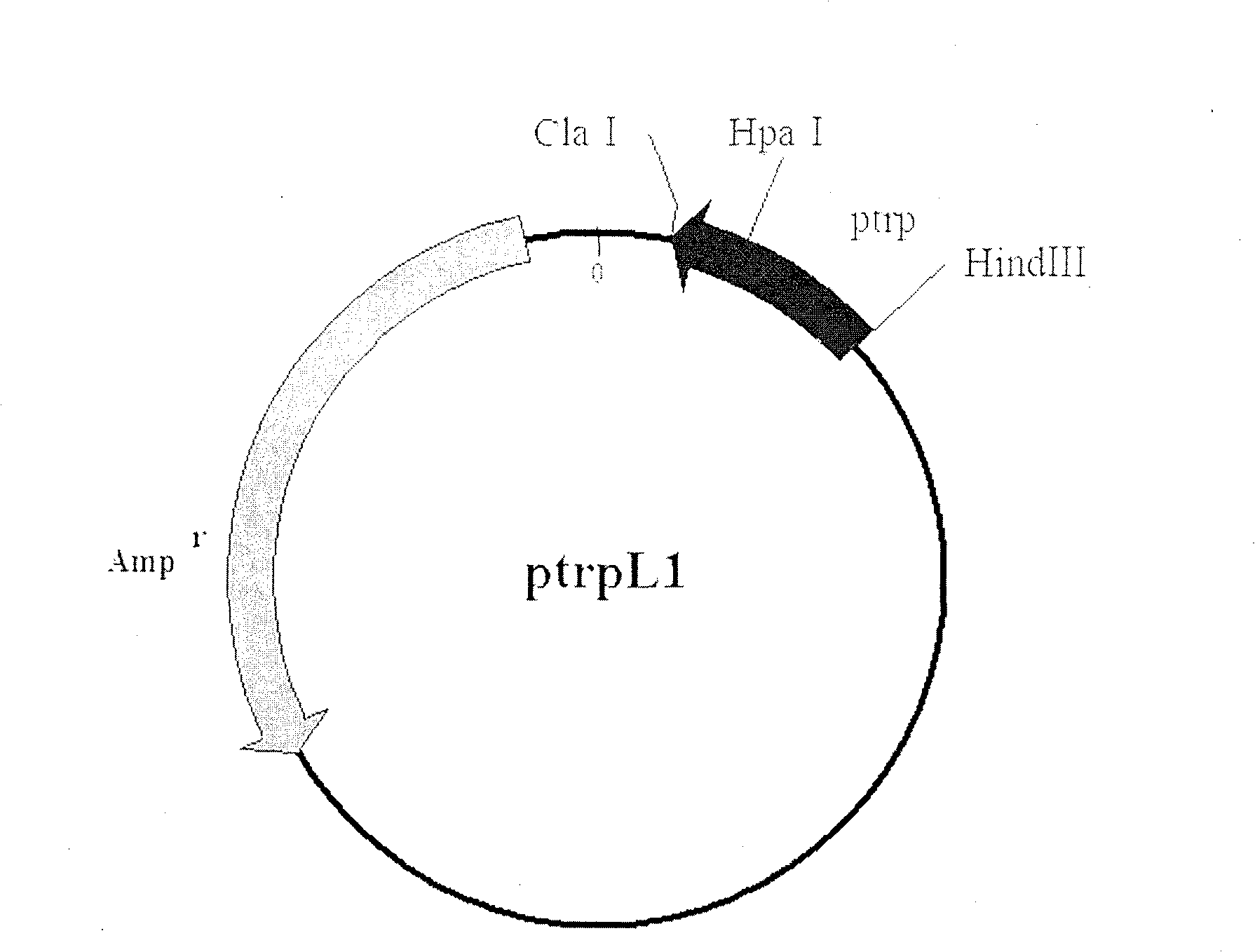

[0035] Example 1: Design of tryptophan tandem promoter sequence

[0036] The tryptophan tandem promoter is derived from the ptrpL1 plasmid (purchased from Stratagene, Germany), and the plasmid map is attached to the instructions. figure 2The tryptophan promoter of this plasmid is derived from the tryptophan operon of Escherichia coli K12 strain. It is a strong promoter suitable for industrial production applications. There is a Cla I restriction site between the SD sequence and the start codon sequence At the same time, there is a HindIII restriction site upstream of the -35 region of the tryptophan promoter, which is convenient for connecting the promoter to other expression vectors. Since the two tryptophan promoters are connected in series, the expression intensity can be improved, so , based on the tryptophan promoter of the ptrpL1 plasmid, a tryptophan tandem promoter was synthesized by total gene synthesis.

[0037] By optimizing the tryptophan tandem promoter, the Hin...

Embodiment 2

[0039] Embodiment 2: the design of proline-4-hydroxylase gene sequence

[0040] According to the codon usage frequency of Escherichia coli to optimize the gene codon, eliminate the codon with low usage rate, and use the synonymous transformation method to eliminate HindIII, BamH I, EcoR I restriction sites, so the original sequence and The terminator was changed to TAAT strong terminator. In order to facilitate the connection of the proline-4-hydroxylase gene to other plasmid vectors, a restriction site BamH I (GGATCC) was inserted behind the terminator.

[0041] The secondary structure of mRNA should also be taken into consideration. First of all, it is necessary to ensure that the codon translation pocket consisting of several bases after the AUG start codon is open to reduce the energy potential of ribosomes binding to mRNA, so that ribose The body can be smoothly translated backwards along the start codon.

[0042] For the original sequence of the proline-4-hydroxylase ge...

Embodiment 3

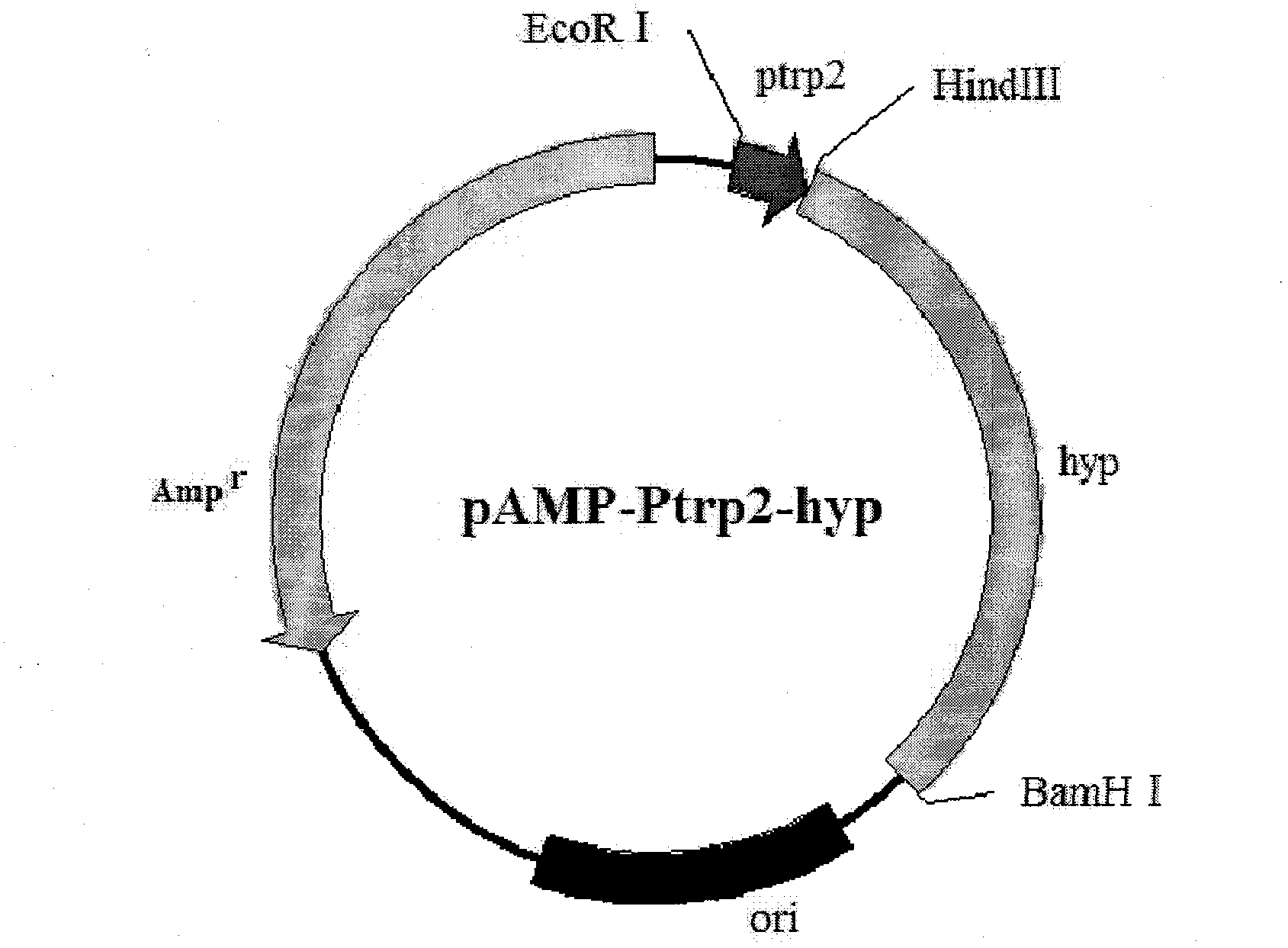

[0043] Embodiment 3: Construction of proline-4-hydroxylase gene expression vector and recombinant Escherichia coli

[0044] Synthesize the designed tryptophan tandem promoter and proline-4-hydroxylase gene respectively first, since the 5-terminal sequence of the tryptophan tandem promoter gene sequence has an EcoR I (GAATTC) restriction site, the 3' There is a HindIII (AAGCTT) restriction site at the end, and the 5' end sequence of the proline-4-hydroxylase gene has a HindIII (AAGCTT) restriction site, and there is a BamH I (GGATCC) restriction site at the 3' end point. The tryptophan tandem promoter gene sequence was double-digested with restriction endonucleases EcoR I and HindIII, and the proline-4-hydroxylase gene was double-digested with HindIII and BamH I. At the same time, the plasmid vector pAMP was also digested They were digested with EcoR I and BamH I, respectively. Recover the tryptophan tandem promoter gene sequence, proline-4-hydroxylase gene and pAMP plasmid v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com