High compressive strength ratio concrete and preparation method thereof

A fold-to-compression ratio and concrete technology, which is applied to high fold-to-compression ratio concrete and its preparation, high fold-to-compression ratio concrete material and its preparation field, can solve the problem of limited improvement of flexural strength, increased engineering cost, poor construction performance, etc. problems, to achieve the effect of improving the compactness and strength, reducing the water-binder ratio, and improving the state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

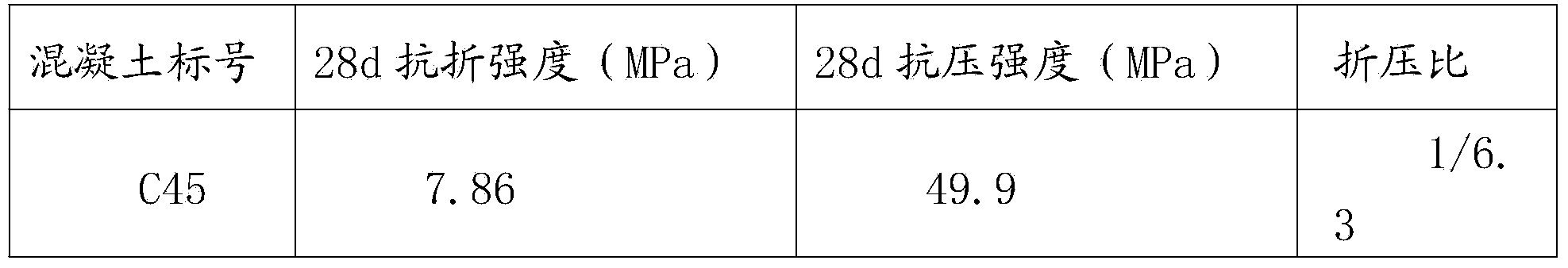

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of high compression ratio concrete and its preparation method

[0024] The first step: Weigh the raw materials according to the following mixing ratio, cement: mineral powder: fly ash: porous basalt: blast furnace slag: water: admixture=7.0kg:2.0kg:1.5kg:20.8kg:13.6kg:3.4kg: 250g; ordinary Portland cement with a cement grade of 42.5; the porous basalt is continuously graded porous basalt with a particle size of 5-20 mm; the admixture is an aliphatic water reducer; the water-quenched blast furnace slag The fineness modulus is 2.3~3.0. The porosity of the porous basalt is 35%. The saturated surface dry water absorption of the water-quenched blast furnace slag is 9%.

[0025] Step 2: Add porous basalt, water-quenched blast furnace slag and water into the mixer to fully soak the coarse and fine aggregates, and stir for 1 minute;

[0026] Step 3: Add cement, slag powder, fly ash and admixtures into the mixer, fully stir until uniform;

[0027] Step 4...

Embodiment 2

[0031] Embodiment 2: A kind of high compression ratio concrete and its preparation method

[0032] The first step: Weigh the raw materials according to the following mixing ratio, cement: mineral powder: fly ash: porous basalt: blast furnace slag: water: admixture=6.0kg:1.5kg:1.5kg:21.0kg:15.2kg:3.4kg: 235g;

[0033] The cement is ordinary Portland cement with a strength grade of 42.5R; the porous basalt is continuously graded porous basalt with a particle size of 5-20 mm; the admixture is an aliphatic water reducer; the water The fineness modulus of quenched blast furnace slag is 2.4-2.9. The porosity of the porous basalt is 39%. The saturated surface dry water absorption of the water-quenched blast furnace slag is 10%.

[0034] Step 2: Add porous basalt, water-quenched blast furnace slag and water into the mixer to fully soak the coarse and fine aggregates, and stir for 1 minute;

[0035] Step 3: Add cement, slag powder, fly ash and admixtures into the mixer, fully stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com