Separation-flotation technology of rough sand and secondary slime of vein gold ores

A secondary slime and coarse sand technology, applied in the field of flotation technology, can solve problems such as increased waste gas treatment costs, high environmental protection pressure, and serious equipment corrosion, so as to improve resource utilization efficiency, increase gold recovery rate, and reduce environmental pollution. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

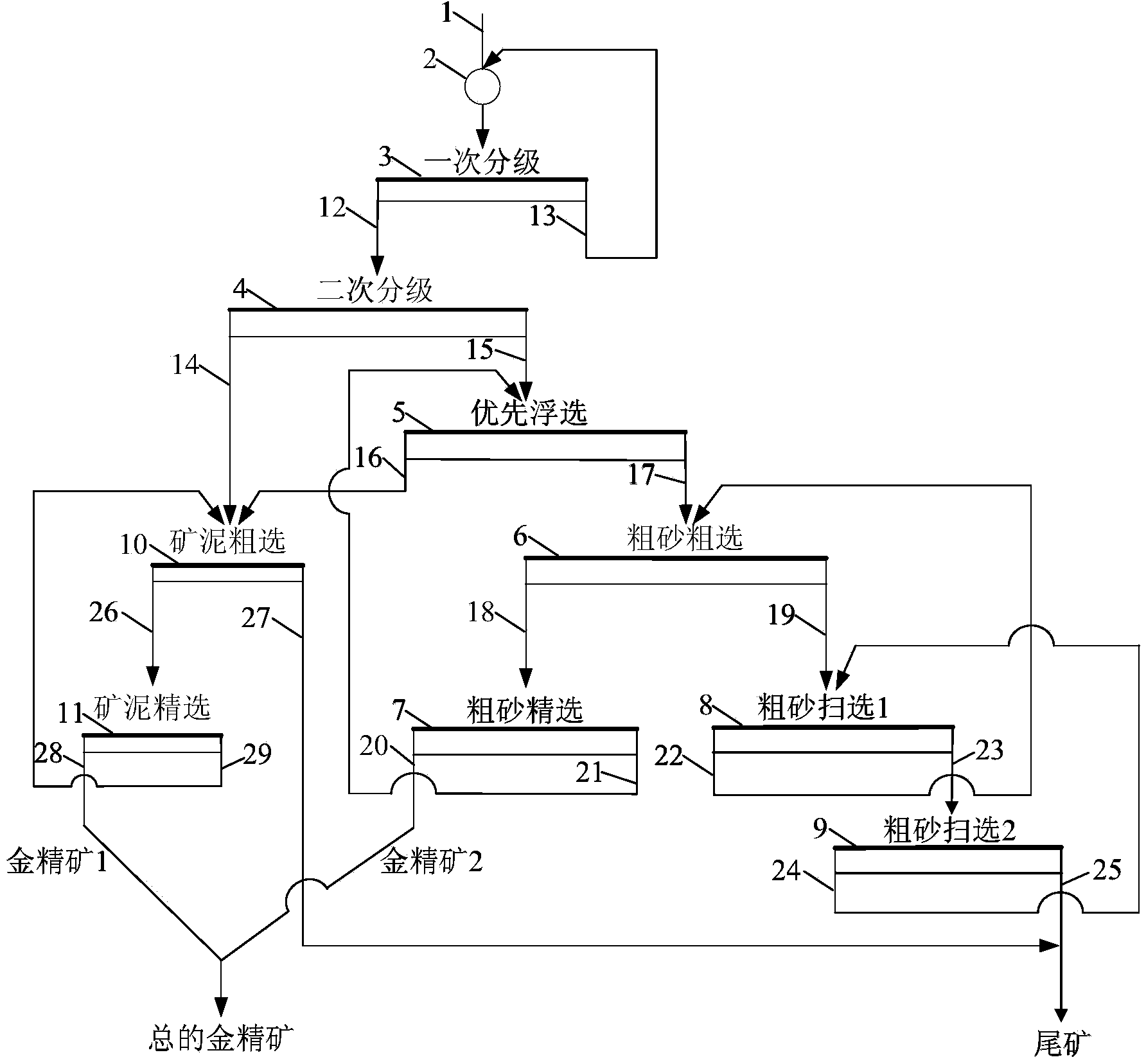

[0030]The vein gold ore raw ore is subjected to grinding and classification operations consisting of grinding, primary classification, and secondary classification. The primary classification uses a Taylor standard sieve with a mesh size of 0.150mm, and the secondary classification uses a Taylor standard sieve with a mesh size of 0.044mm. Secondary graded coarse sand and secondary graded secondary slime;

[0031] The secondary graded coarse sand obtained from the grinding and grading operation passes through the flotation circuit composed of priority flotation, coarse sand roughing, coarse sand selection, coarse sand sweeping 1, and coarse sand sweeping 2. Amyl xanthate 40g / t, terpineol oil 30g / t; coarse sand sweeping 1, add isoamyl xanthate 20g / t, terpineol oil 15g / t; coarse sand sweeping 2, add isopentyl xanth 20g / t t, pine alcohol oil 15g / t; coarse sand roughing (6), coarse sand selection (7) do not add chemicals; coarse sand selection returns to the priority flotation, coa...

Embodiment 2

[0037] Grinding and classifying operation is identical with embodiment 1;

[0038] The secondary graded coarse sand obtained from the grinding and grading operation passes through the flotation circuit composed of priority flotation, coarse sand roughing, coarse sand selection, coarse sand sweeping 1, and coarse sand sweeping 2. Amyl xanthate 50g / t, terpineol oil 30g / t; coarse sand sweeping 1, add isoamyl xanthate 30g / t, terpineol oil 15g / t; coarse sand sweeping 2, add isopentyl xanth 30g / t t, pine alcohol oil 15g / t; coarse sand roughing (6), coarse sand selection (7) do not add chemicals; coarse sand selection returns to the priority flotation, coarse sand sweeping 1 returns the middle ore To coarse sand roughing, the middle ore of coarse sand scavenging 2 returns to coarse sand scavenging 1, and the underflow of coarse sand scavenging 2 enters the tailings, and the foam product and gold concentrate 2 of priority flotation are obtained;

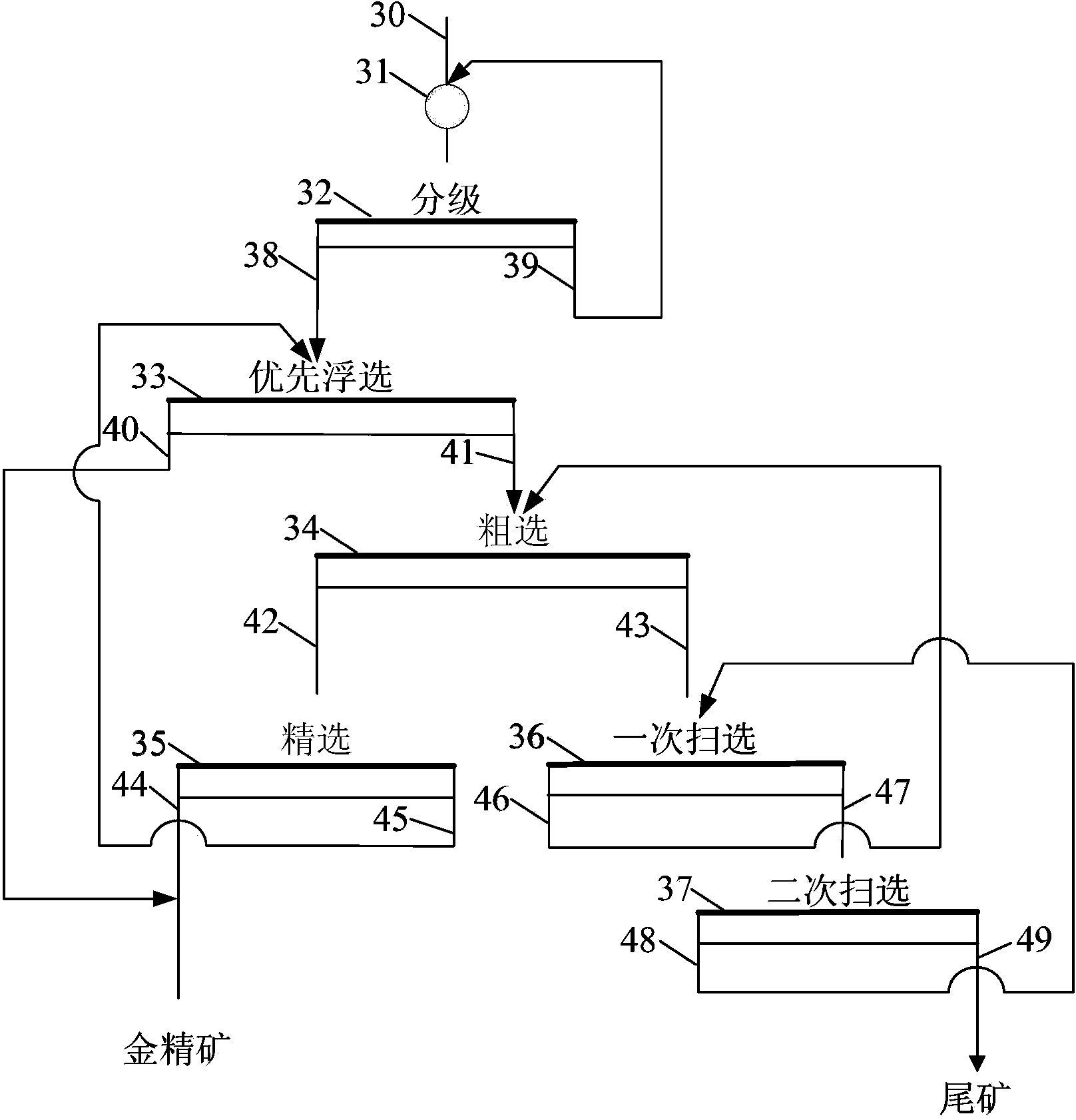

[0039] The secondary graded secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com