Manufacturing method of melamine microcapsule

A technology of melamine and manufacturing method, which is applied in the direction of microcapsule preparation, microcapsule, microsphere preparation, etc., can solve the problems of poor specific gravity, weakened effect, poor stability of capsule dispersion, etc., and achieve the effect of reducing the residual amount of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

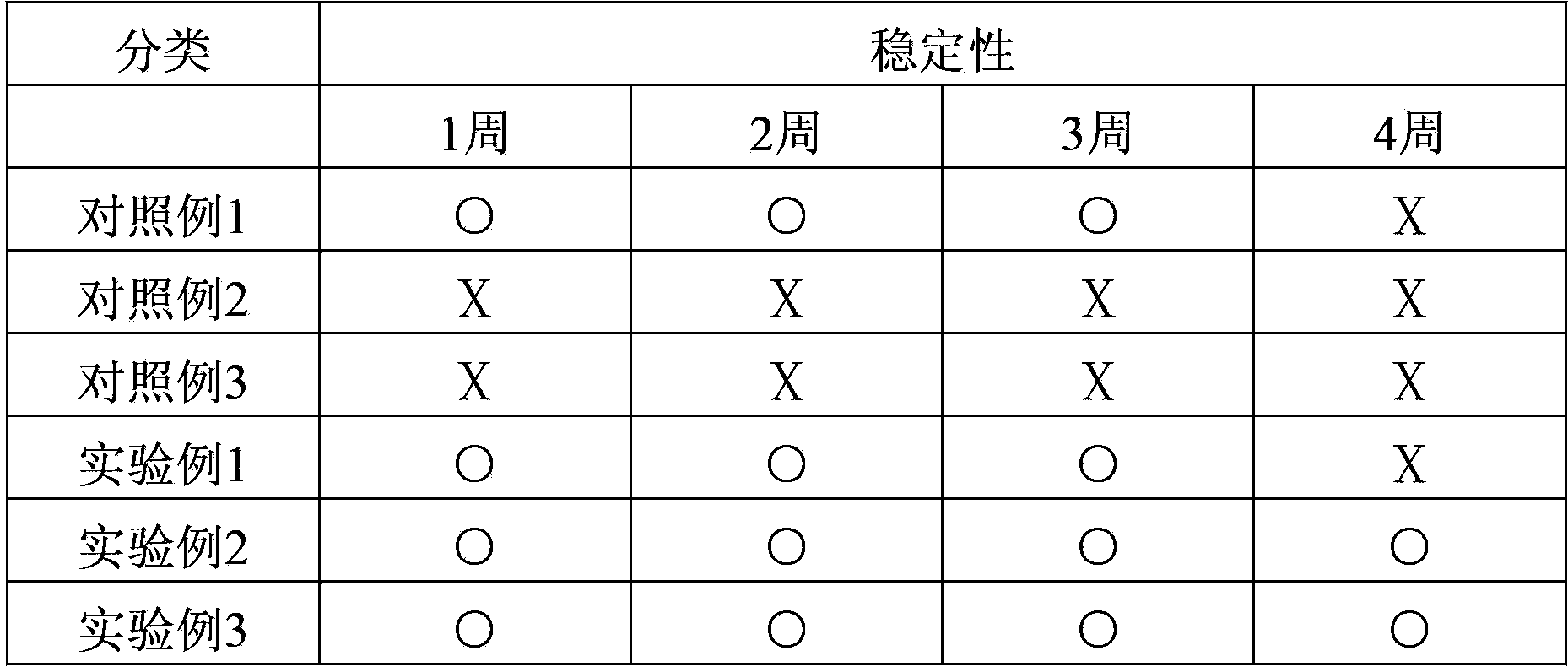

Examples

experiment example 1

[0081] Add 10 g of melamine, 40 g of distilled water, 20 g of formaldehyde solution, and 0.05 g of sodium hydroxide to a 1 L four-neck flask to adjust the pH to 9, add 21 g of diethylenetetramine (polyamine), and stir at 80°C The melamine-formaldehyde prepolymer (Prepolymer) was produced in 30 minutes. As the aqueous formaldehyde solution, an aqueous solution containing 35% by weight of formaldehyde relative to 100% by weight of the aqueous formaldehyde solution was used.

[0082] In another 1L beaker, ethylene-maleic acid copolymer resin (trade name: EMA-31, product of Monsanto Co., Ltd.) was alkalized with sodium hydroxide to produce 200 g of an emulsifier, which acts as an anionic surfactant, and then added to it 100 g of rose oil was added as a capsule core substance, and stirred at a speed of 3,000 rpm for about 10 minutes using a high-speed mixer to manufacture an oily / watery (O / W) emulsion. The emulsifier contained 5% by weight of ethylene-maleic acid copolymer resin r...

experiment example 2

[0085] Add 10 g of melamine, 40 g of distilled water, 20 g of formaldehyde solution, and 0.05 g of sodium hydroxide to a 1 L four-neck flask to adjust the pH to 9, add 7 g of diethylenetetramine (polyamine), and stir at 80°C The melamine-formaldehyde prepolymer (Prepolymer) was produced in 30 minutes. As the aqueous formaldehyde solution, an aqueous solution containing 35% by weight of formaldehyde relative to 100% by weight of the aqueous formaldehyde solution was used. The stirring is performed at a speed of 100 rpm.

[0086] In another 1L beaker, ethylene-maleic acid copolymer resin (trade name: EMA-31, product of Monsanto Co., Ltd.) was alkalized with sodium hydroxide to produce 200 g of an emulsifier, which acts as an anionic surfactant, and then added to it 100 g of rose oil was added as a capsule core substance, and stirred at a speed of 3,000 rpm for about 10 minutes using a high-speed mixer to manufacture an oily / watery (O / W) emulsion. The emulsifier contained 5% by...

experiment example 3

[0090]Add 10 g of melamine, 40 g of distilled water, 20 g of formaldehyde solution, and 0.05 g of sodium hydroxide to a 1 L four-neck flask to adjust the pH to 9, add 7 g of diethylenetetramine (polyamine), and stir at 80°C The melamine-formaldehyde prepolymer (Prepolymer) was produced in 30 minutes. As the aqueous formaldehyde solution, an aqueous solution containing 35% by weight of formaldehyde relative to 100% by weight of the aqueous formaldehyde solution was used. The stirring is performed at a speed of 100 rpm.

[0091] Ethylene-maleic acid copolymer resin (trade name: EMA-31, product of Monsanto Co., Ltd.) was basified with sodium hydroxide in a separate 1 L beaker. An emulsification functioning as an anionic surfactant was produced by basifying with sodium hydroxide. 200 g of the preparation, and 100 g of rose oil as a capsule core substance was added thereto and stirred at a speed of 3,000 rpm for about 10 minutes using a high-speed mixer to manufacture an oily / wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com