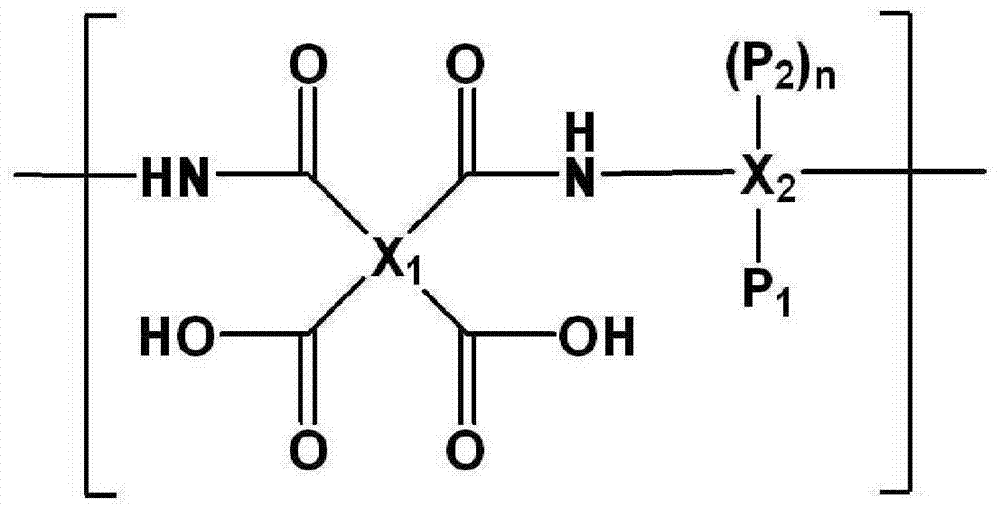

Novel polyamic acid, photosensitive resin composition, dry film and circuit board

A polyamic acid, chemical formula technology, applied in printed circuits, printed circuits, printed circuit manufacturing and other directions, can solve problems such as limitations in the development of circuit protection films, difficulty in realizing weak alkaline aqueous solution development characteristics, and reduction in space filling characteristics. Provides the effect of process stability and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0261] [Preparation Example 1] Preparation of polyamic acid (PAA1)

[0262] In a 4-necked round-bottom flask equipped with a thermometer, stirrer, nitrogen input port, and powder distribution funnel, 38 g of 4,4′-oxodiphthalic anhydride (ODPA) was dispersed into 150 g of In a mixed solvent of toluene and dimethylacetamide (weight ratio: 3:7).

[0263] Then, 23.2 g of 4,4′-oxodiphenylamine (4,4′-ODA) and 2.59 g of DPIM obtained in the synthesis example were completely dissolved in the above solution under stirring, and then the resulting product was stirred again 24 hours to obtain polyamic acid varnish.

[0264] The varnish solution had a solids content of 30% by weight and a viscosity of 3400 cps at room temperature.

preparation Embodiment 2

[0265] [Preparation Example 2] Preparation of polyamic acid (PAA2)

[0266] In a 4-necked round-bottomed flask equipped with a thermometer, stirrer, nitrogen gas inlet, and powder distribution funnel, 38 g of 4,4′-oxodiphthalic anhydride (ODPA) was dispersed into 149 g of In a mixed solvent of toluene and dimethylacetamide (weight ratio: 3:7).

[0267] Then, 20.6 g of 4,4′-oxodiphenylamine (4,4′-ODA) obtained in Synthesis Example and 5.19 g of DPIM were completely dissolved in the solution under stirring, and the resulting product was stirred for another 24 hours To obtain polyamic acid varnish.

[0268] The varnish solution had a solids content of 30% by weight and a viscosity of 3600 cps at room temperature.

preparation Embodiment 3

[0269] [Preparation Example 3] Preparation of polyamic acid (PAA3)

[0270] In a 4-necked round-bottomed flask equipped with a thermometer, stirrer, nitrogen gas inlet, and powder distribution funnel, 38 g of 4,4′-oxodiphthalic anhydride (ODPA) was dispersed into 149 g of In a mixed solvent of toluene and dimethylacetamide (weight ratio: 3:7).

[0271] Then, 25.8 g of 4,4′-oxodianiline (4,4′-ODA) was completely dissolved in the solution with stirring, and the resulting product was further stirred for 24 hours to obtain a polyamic acid varnish.

[0272] The varnish solution had a solids content of 30% by weight and a viscosity of 3100 cps at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com