Oxide-based transparent RRAM (Resistive Random Access Memory) and preparation method thereof

An oxide and transparent technology, used in electrical components and other directions, can solve the problems of difficult to guarantee process repeatability, low impedance top electrode, high production cost, low investment in equipment and raw materials, and good consistency , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

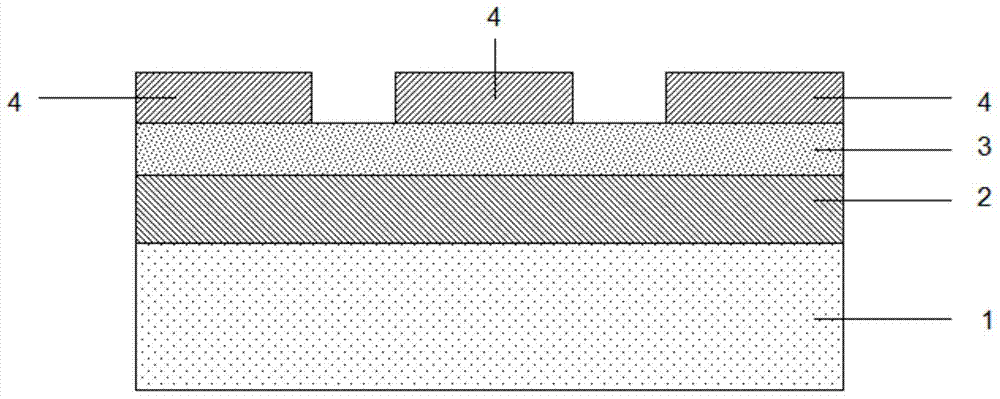

[0030] see figure 1 , in this embodiment, the substrate is a glass substrate 1, the material of the lower electrode 2 is FTO (fluorine tin oxide), and the material of the resistive layer film 3 is ZrO 2 , the material of the upper electrode 4 is ITO (indium tin oxide). The basic process steps are as follows:

[0031] 1) Clean the substrate: Use an ultrasonic cleaning machine to clean the glass substrate on which FTO has grown (purchased from Yingkou Opivet New Energy Technology Co., Ltd.). Immerse the glass in acetone, heat the water bath to 50°C, and sonicate for 5 minutes; then immerse the glass in absolute ethanol, heat the water bath to 50°C, and sonicate for 5 minutes.

[0032] 2) Preparation of resistive layer thin film: using sol-gel technology, selecting zirconium n-butoxide (Zr(O 4 h 9 ) 4 ) as a precursor material, acetylacetone (C 5 h 8 o 2 ) as a stabilizer. First, 3.5 mL of zirconium n-butoxide (80 wt% dissolved in n-butanol) was used as a precursor mater...

Embodiment 2

[0036] 1) Cleaning the substrate: Use an ultrasonic cleaner to clean the glass substrate on which FTO has been grown. Immerse the glass in acetone, heat the water bath to 50°C, and sonicate for 7 minutes; then immerse the glass in absolute ethanol, heat the water bath to 50°C, and sonicate for 7 minutes.

[0037] 2) Preparation of resistive layer film: first, 4.0mL zirconium n-butoxide (80wt% dissolved in n-butanol) was used as a precursor material, mixed with 10mL absolute ethanol at room temperature, and stirred. Two minutes later, 2 mL of acetylacetone (C 5 h 8 o 2), the solution was milky white. Add 2.5 mL of acetic acid dropwise and continue to stir, the solution becomes clear and slightly pale yellow. Maintain a rotation speed of 3000 rpm for 60 seconds, and then deposit a thin film on the substrate by spin coating. After the film is fabricated, it is baked on a hot plate at 160° C. for 5 minutes to remove the organic components, and the production of the resistive ...

Embodiment 3

[0041] In this embodiment, the substrate is a glass substrate, the material of the lower electrode 2 is ZTO (zinc tin oxide), and the material of the resistive layer film 3 is ZrO 2 , the material of the upper electrode 4 is ZTO. The basic process steps are as follows:

[0042] 1) Clean the substrate: Use an ultrasonic cleaner to clean the glass substrate that has grown ZTO (prepared by solid-state sintering method). Immerse the glass in acetone, heat the water bath to 60°C, and sonicate for 3 minutes; then immerse the glass in absolute ethanol, heat the water bath to 60°C, and sonicate for 3 minutes.

[0043] 2) Preparation of resistive layer film: 3.0mL zirconium n-butoxide (80wt% dissolved in n-butanol) was used as a precursor material, mixed with 10mL absolute ethanol at room temperature, and stirred. Two minutes later, 2 mL of acetylacetone (C 5 h 8 o 2 ), the solution was milky white. Add 2.0 mL of acetic acid dropwise and continue to stir, the solution becomes cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com