Preparation method of boron-doped p type carbon nanotube with high seebeck coefficient

A technology with high Seebeck coefficient and carbon nanotubes, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of difficult improvement of thermoelectric figure of merit, difficulty of thermoelectric conversion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

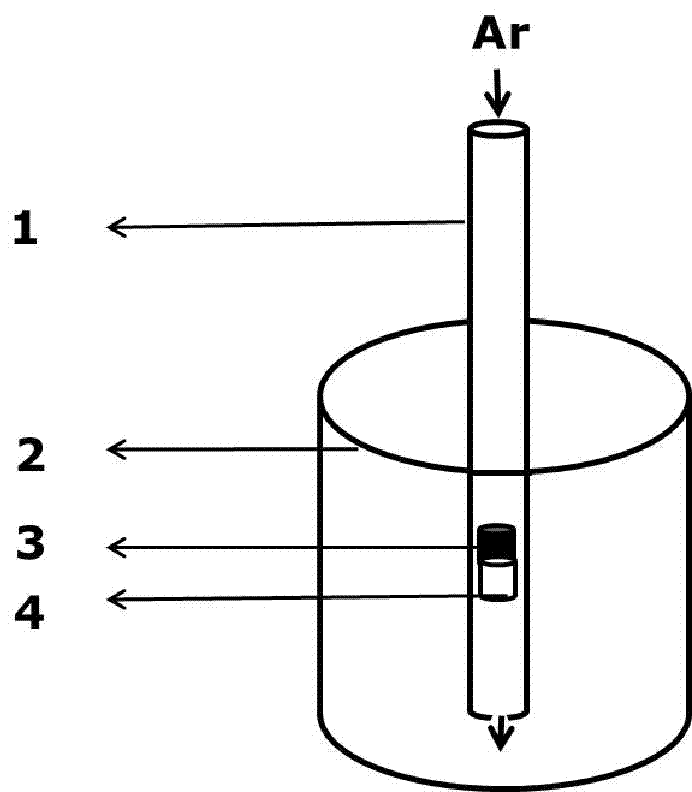

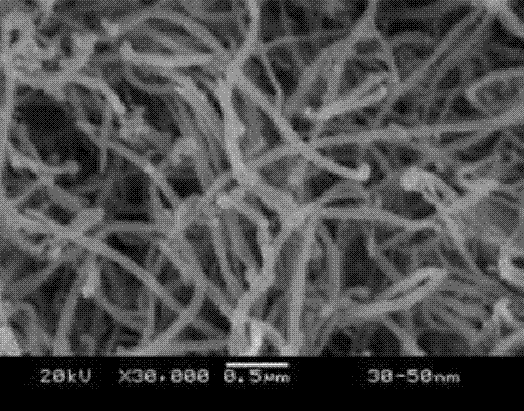

[0025] Example 1: Multi-walled carbon nanotubes prepared by chemical vapor deposition (Purity: >95%, OD: 30-50nm [OD=Outer Diameter] ID: 5-12nm [ID=Inner Diameter] Length: 10-20um ) and B 2 o 3 as the initial raw material. After mixing the solid powders of the two raw materials with different ratios evenly, dry them in a vacuum oven at 80°C for 1 to 8 hours, then put them into a φ20×40mm cylindrical corundum crucible, and then put the crucible into figure 1 In the shown ceramic tube, the upper end of the ceramic tube is connected to the argon cylinder, and the lower end of the ceramic tube is connected to the vacuum device. The specific operation is to close the upper argon gas intake switch first, and turn on the lower vacuum pump switch; then close the vacuum pump switch, open the argon gas intake switch, and cycle the above operation for 5 times (the purpose of the cycle is to exhaust the air in the ceramic tube ) Turn off the vacuum switch, and at the same time turn on ...

Embodiment 2

[0033] Example 2: Single-walled carbon nanotubes prepared by chemical vapor deposition (Purity: >90% OD: 1-2nm [OD=Outer Diameter] ID: 0.8-1.6nm [ID=Inner Diameter] Length: 5-30um ) and B 2 o 3 as the initial raw material. After mixing the solid powders of the two raw materials with different ratios evenly, dry them in a vacuum oven at 80°C for 1 to 8 hours, then put them into a φ20×40mm cylindrical corundum crucible, and then put the crucible into figure 1 In the shown ceramic tube, the upper end of the ceramic is connected to the argon cylinder, and the lower end is connected to the vacuum device. The specific operation is to first close the upper argon gas intake switch, open the lower end vacuum switch, then close the vacuum switch, open the argon gas intake switch, and cycle the above operation 5 times (the purpose of the cycle is to discharge the air in the ceramic tube into ) Turn off the vacuum switch, and at the same time turn on the exhaust switch at the lower end...

Embodiment 3

[0038] Example 3: Multi-walled carbon nanotubes prepared by arc method (Purity: >95% OD: 30-50nm [OD=Outer Diameter] ID: 5-12nm [ID=Inner Diameter] Length: 10-20um) and boric acid h 3 BO 3 as the initial raw material. After mixing the solid powders of the two raw materials with different ratios evenly, dry them in a vacuum oven at 80°C for 1 to 8 hours, then put them into a φ20×40mm cylindrical corundum crucible, and then put the crucible into figure 1 In the shown ceramic tube, the upper end of the ceramic is connected to the nitrogen cylinder, and the lower end is connected to the vacuum device. The specific operation is to first turn off the argon gas inlet switch at the upper end, turn on the vacuum pumping switch at the lower end, then turn off the vacuum pumping switch, turn on the nitrogen gas inlet switch, and cycle the above operation 5 times (the purpose of the cycle is to discharge the air in the ceramic tube) Turn off the vacuum switch, and at the same time turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Seeback coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com