Method for overlap welding of steel bars

A technology of lap welding and steel bars, which is applied in the field of steel bar lap welding, can solve problems affecting welding quality, etc., and achieve the effects of preventing welding porosity defects, increasing welding speed, and reducing manpower hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

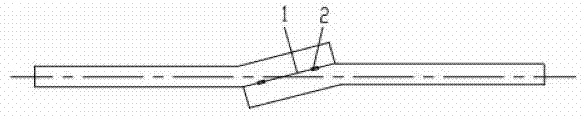

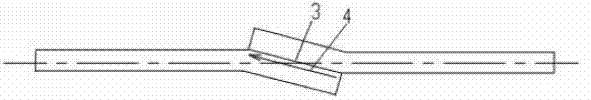

[0025] control Figure 1-4 The operation steps of the present invention are further described:

[0026] A drug core CO 2 The method for lap welding of steel bars with gas shielded welding wire is characterized in that: the welding equipment uses an inverter CO 2 Gas shielded welding machine, using ER501T-1 CO 2 Flux cored gas shielded welding wire, the steel bar is HRB335 with Φ20mm-30mm steel bar;

[0027] The welding method is as follows:

[0028] 1) Lap the steel bars and spot weld them;

[0029] 2) Root-layer welding of steel bar lap welds: the arc moves in a straight line 4, welding parameters: welding current is 260A, welding voltage is 23V, welding speed is 35-40cm / min;

[0030] 3) Carry out cover layer welding on the root layer weld: the arc moves in a zigzag shape 5, welding parameters: welding current is 260A, welding voltage is 23V, and welding speed is 25-35cm / min.

[0031] The said overlapping of steel bars means that the ends of two steel bars are folded an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com