Disassembly device for reusable surface-mounted components of waste circuit board

A technology for discarding circuit boards and components is applied in the field of dismantling equipment for components mounted on discarded circuit boards. The effect of increasing efficiency, reducing pre-processing and set-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below through embodiments in conjunction with the accompanying drawings.

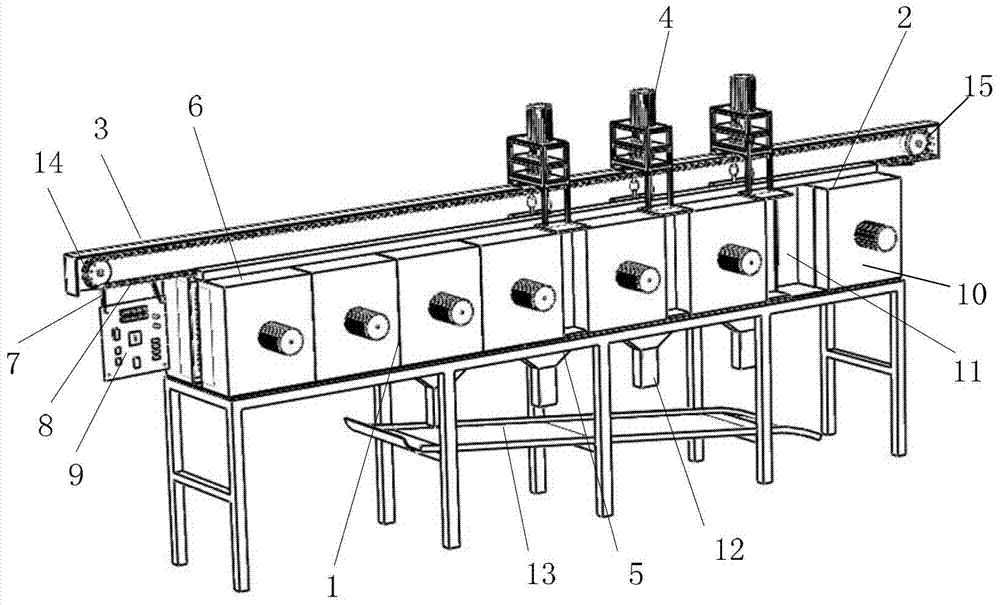

[0046] like figure 1Shown is a schematic diagram of the overall structure of the first embodiment of the present invention, the equipment is composed of a heating system 1, a cooling system 2, a conveying system 3, a sweeping system 4 and a component collection structure 5; the heating system 1 consists of six upright The heating temperature zone 6 is composed of; the cooling system 2 is composed of an upright cooling temperature zone 10; there is a transition zone 11 between the sixth heating temperature zone 6 and the cooling temperature zone 10, and there is no forced convection wind to prevent the sixth heating The temperature is connected in series between the temperature zone 6 and the cooling temperature zone 10; the transmission chain 8 of the transmission system 3 is located above all the temperature zones of the heating system 1, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com