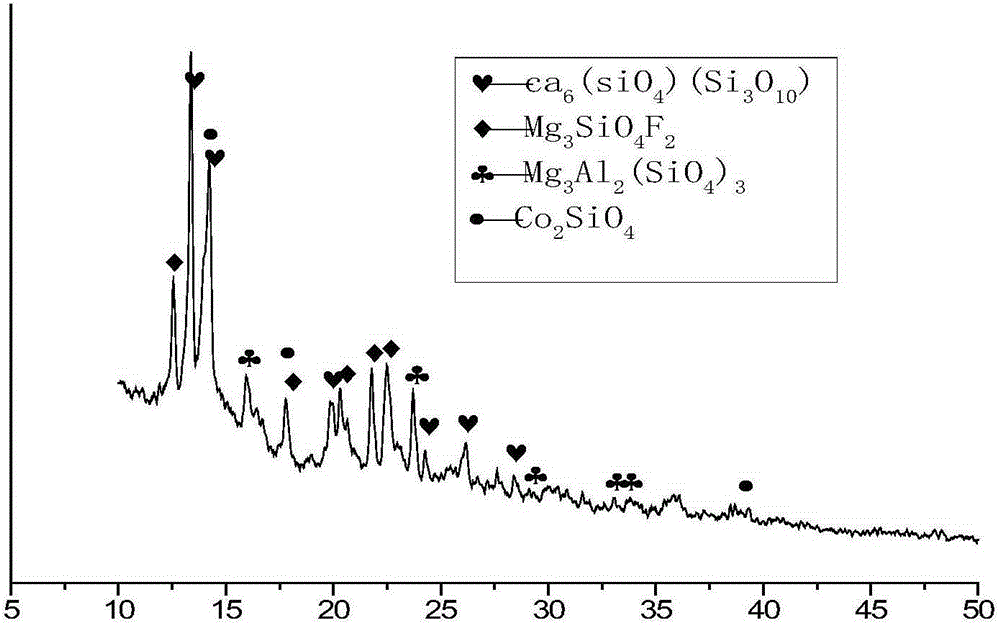

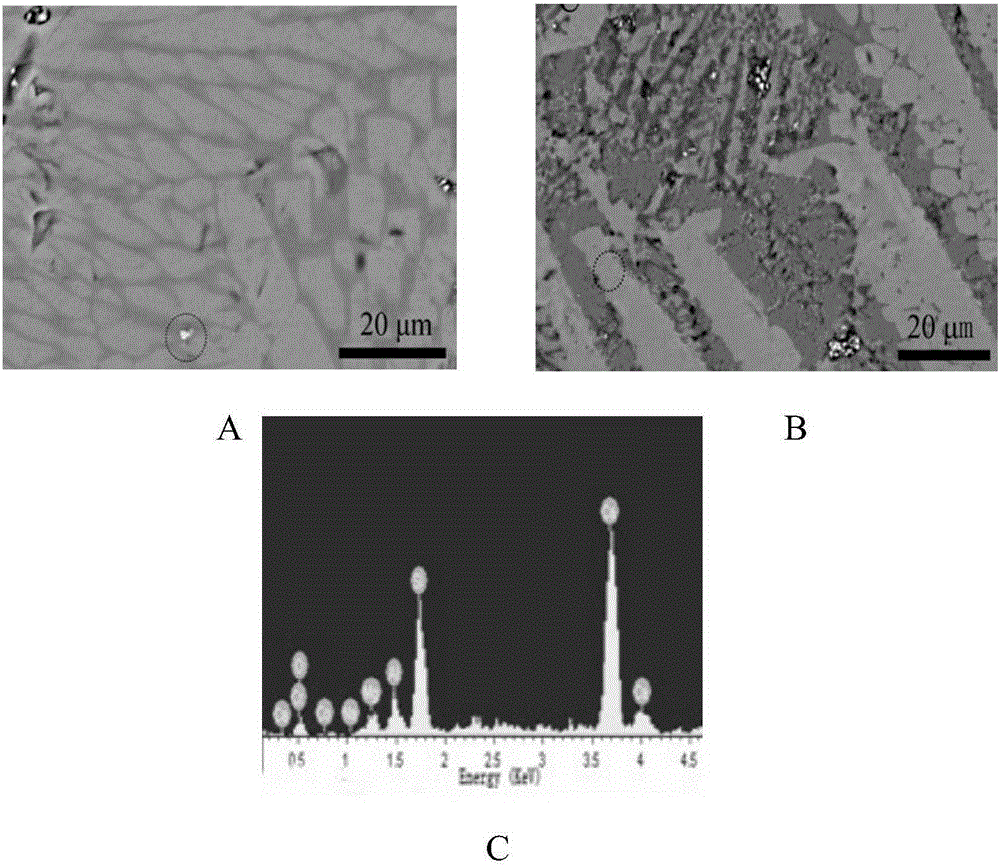

Peritectic steel mold flux containing cobalt oxide and preparation method thereof

A technology of mold slag and cobalt oxide, which is applied in the field of iron and steel metallurgy, can solve problems such as the inability to effectively control the heat flux of mold slag, and achieve the effects of increasing radiation heat absorption capacity, reducing heat flux, and reducing heat flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

[0031] Formula for preparing mold flux:

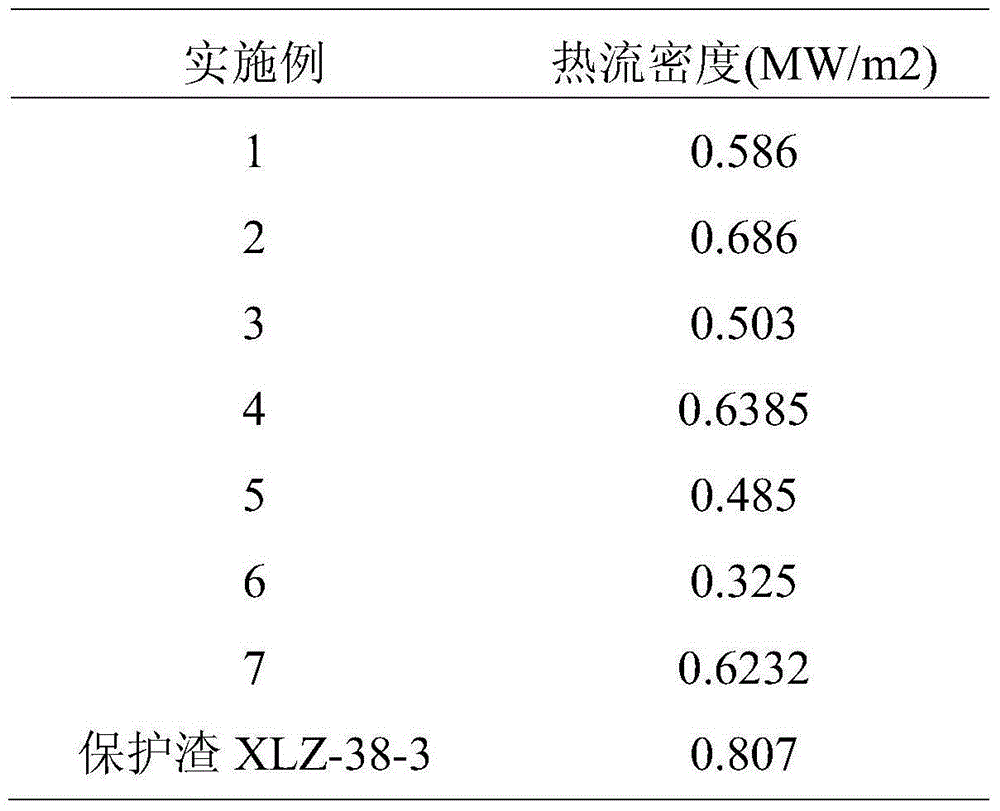

[0032] Example Na 2 o MgO al 2 o 3 CaF 2 C co 2 o 3 CaO SiO 2 Alkalinity 1 5 12 2 20 3 10 28 20 0.9 2 12 3 8 3 12 0.1 32.9 29 1.8 3 10 10 3 15 9 5 28.8 19.2 1.2 4 8.5 5 6 10 6 4 35.5 25 1.3 5 8 2.5 3.5 7 5 1.5 44.5 28 1.6 6 6 5 3.5 10 8 2.5 32.5 32.5 1.4 7 8 2.53 3.7 7 4 1 48.29 25.48 1.0

[0033] The preparation method of mold flux is the prior art: spray granulation technology is used to produce mold flux, and natural mineral wollastonite, bauxite, dolomite, fluorite, or pre-melted slag are used as raw materials. When the alkalinity is not enough, use analytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com