Method for testing and evaluating dynamic morphology features of material during corrosion process

A technology of corrosion process and topographic features, which is applied in the field of dynamic topographic feature testing and evaluation of material corrosion process to achieve the effects of complete dynamic information, simple processing process, and accurate feature determination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] This implementation mode includes the following steps:

[0040] Step 1: wire-cut 45# steel parts that have been in service for 3 days, 6 days, 9 days, and 12 days in a 3.5% NaCl solution environment into test samples with a size of 10mm×10mm×2mm, rinse with deionized water for 5 minutes, and use a mass concentration Ultrasonic cleaning with 10% acetone for 10 minutes, the frequency of ultrasonic cleaning is 20KHz, rinse with ultrapure water, dry and set aside;

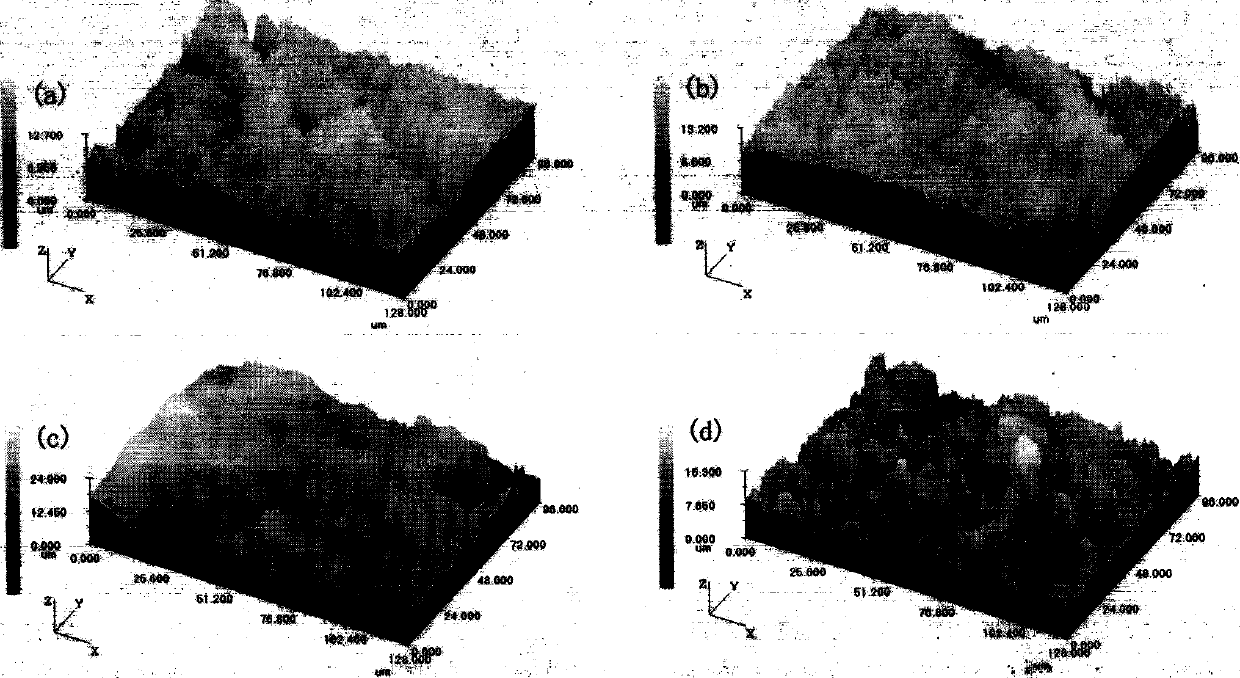

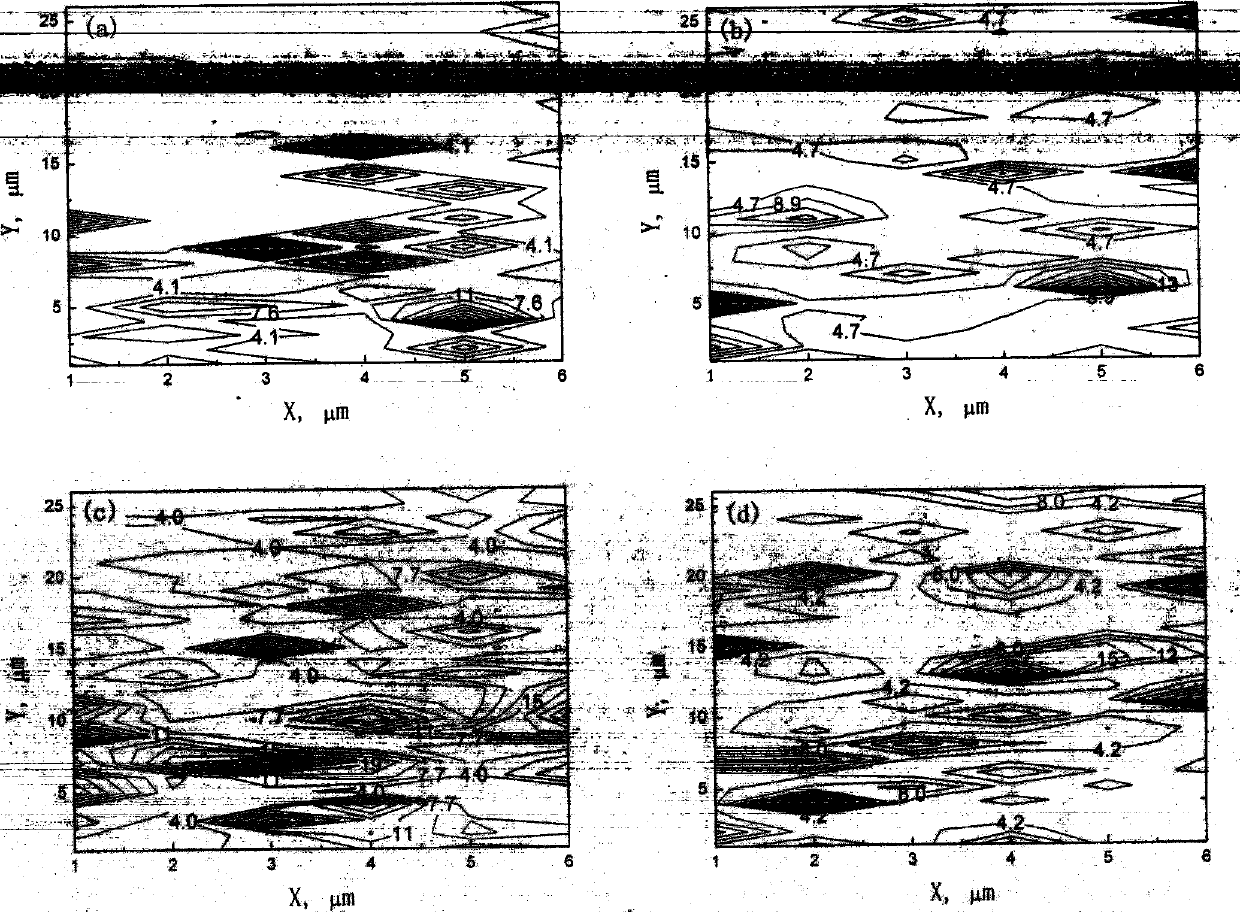

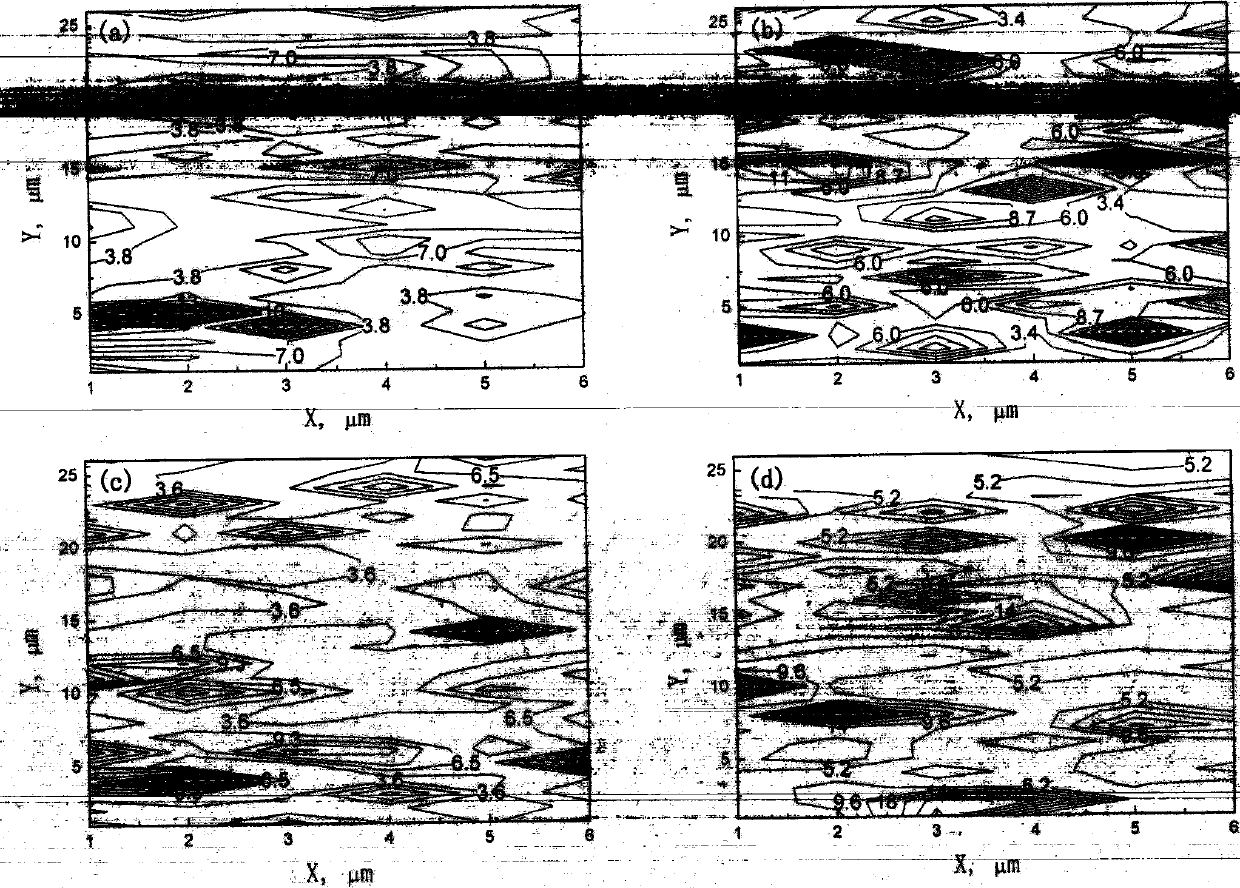

[0041] Step 2: Use the Olympus OLS3000 laser confocal microscope to image the surface of the corrosion history of the sample treated in step 1, as shown in figure 1 As shown, and set the shape measurement area of 128μm×96μm, the three-dimensional direction cut-off frequency of 2800Hz, and the sampling interval of 0.125μm to record the three-dimensional coordinate data;

[0042] Step 3: According to the actual situation, the diameter of the pipe is 0.03 meters, the flow rate is 0.1 m / s, the density is 1 kg / m3,...

specific Embodiment approach 2

[0048] This implementation mode includes the following steps:

[0049] Step 1: Wire-cut T2 copper parts that have been in service for 3 days, 6 days, 9 days, and 12 days in a 3.5% NaCl solution environment into test samples with a size of 10mm×10mm×2mm, rinse with deionized water for 5 minutes, and then use a mass concentration of 10% acetone for ultrasonic cleaning for 10 minutes, the frequency of ultrasonic cleaning is 20KHz, then rinse with ultrapure water, dry and set aside;

[0050] Step 2: Use the Olympus OLS3000 laser confocal microscope to image the surface of the corrosion history of the sample treated in step 1, as shown in image 3 As shown, and set the shape measurement area of 128μm×96μm, the three-dimensional direction cut-off frequency of 2800Hz, and the sampling interval of 0.125μm to record the three-dimensional coordinate data;

[0051] Step 3: According to the actual situation, the diameter of the pipe is 0.03 meters, the flow rate is 0.1 m / s, the density...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com