High-power overload 1KPa silicon micropressure sensor chip and manufacturing method

A technology of a pressure sensor and a manufacturing method, applied in the field of high overload 1KPa silicon micro-pressure sensor chip and manufacturing, can solve the problems such as the batch manufacturing process of the silicon piezoresistive pressure sensor micro-pressure sensor, which is easy to implement and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

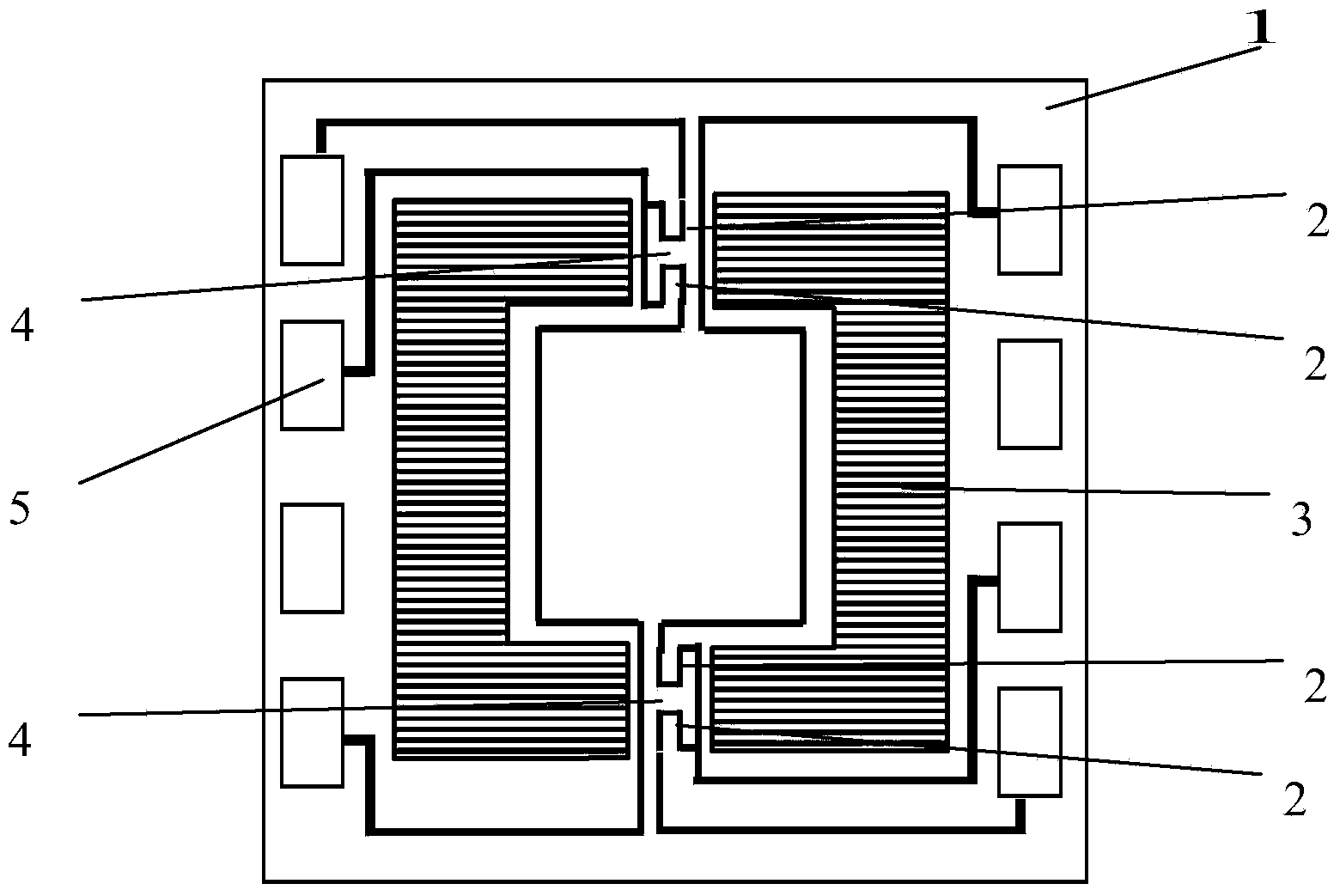

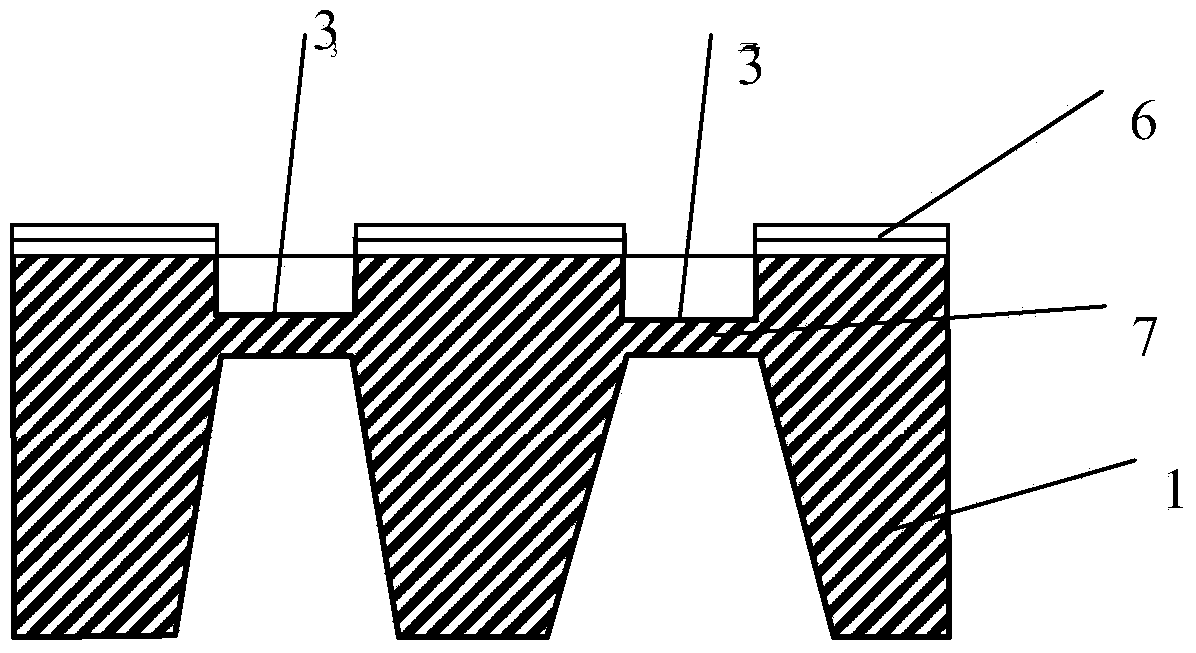

[0028]The high-magnification overload 1KPa silicon micro-pressure sensor chip manufactured by the method of the present invention adopts a 4-inch double-sided polished silicon single wafer, which is characterized in that the structural feature: the microstructure processed on both sides of the upper chip 1: the front "I" beam structure, single rigid membrane structure on the back; see figure 1 , the "back"-shaped shallow groove 3 formed by the corrosion of the upper chip 1, leaving two "I"-shaped beams 4, symmetrically separating the "back" character, and each of the "I"-shaped beams 4 has two single elbows "U" Shaped pressure sensitive resistor, the shallow groove 3 is surrounded by aluminum electrode leads and lead pads 5 . On the back of the upper chip 1, the material other than the thickness of the diaphragm is processed relative to the shallow groove 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com