an oil filter

An oil filter and separator technology, which is used in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc., can solve problems such as poor filtering effect and inability to fully remove oil impurities, and achieve low prices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

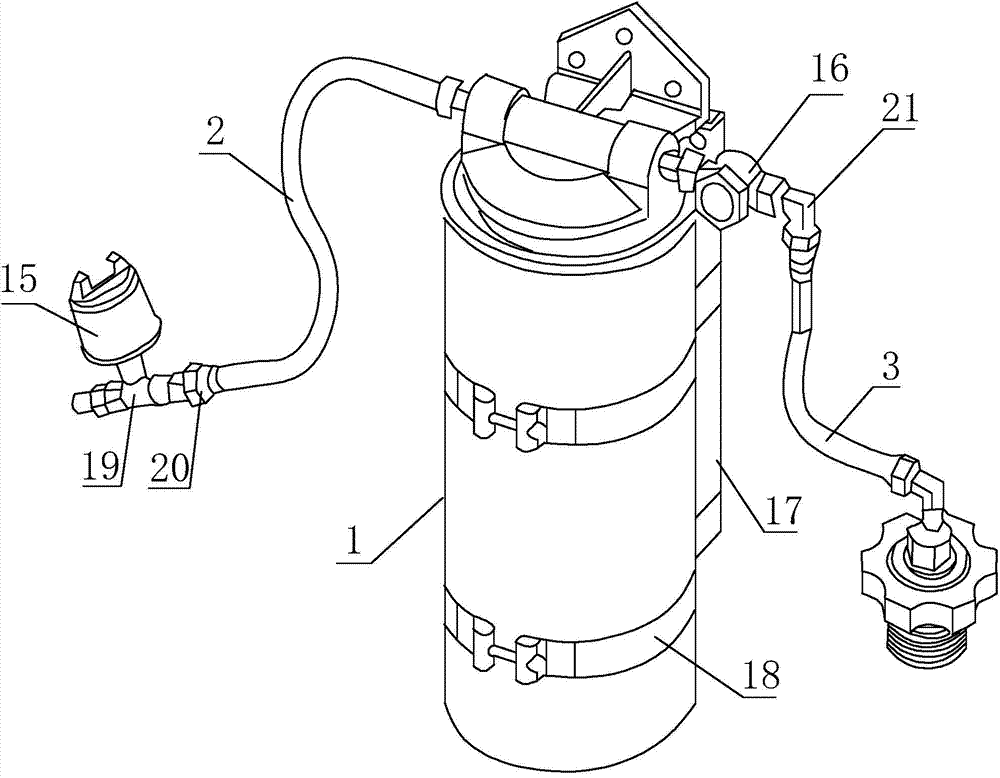

[0022] Referring to the accompanying drawings, an engine oil filter includes a housing 1 , which is divided into a first chamber 101 , a second chamber 102 , a third chamber 103 and a fourth chamber 104 which are connected in sequence. The casing 1 is connected with an oil inlet steel hose 2 and an oil outlet steel hose 3 , the oil inlet hose 2 communicates with the first chamber 101 , and the oil outlet hose 3 communicates with the fourth chamber 104 . The first chamber oil inlet 4 communicating with the oil inlet steel wire hose 2 is arranged on the top of the first chamber 101 . A coarse filter 5 is arranged inside the first chamber 101 , and the mesh diameter of the coarse filter 5 is 2×2 mm. Inside the second chamber 102, a first separator 6, a second separator 7 and a filter body 8 are arranged. Keep a certain distance in the second chamber to separate the filter chamber, the separation chamber and the settling chamber. The filter body 8 is arranged in the filter chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com