Mica paper hot drying machine adopting new energy source

A technology of mica paper and energy, which is applied in the direction of conveyors, filter screens, grilles, etc., can solve the problems of wasting water resources, unable to realize continuous cleaning of mica raw materials, and low cleaning efficiency, so as to achieve improved utilization rate, good washing effect, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings. The description in this section is only exemplary and explanatory and should not have any limitation on the scope of protection of the present invention. .

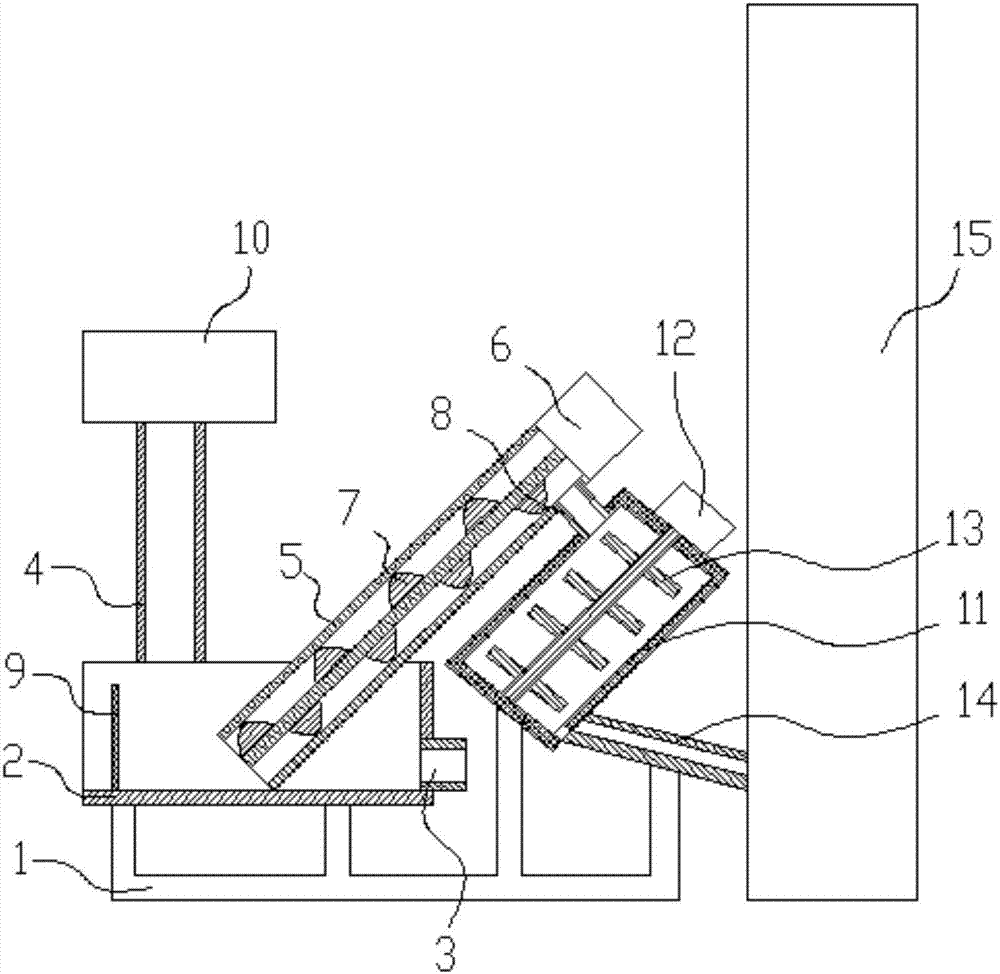

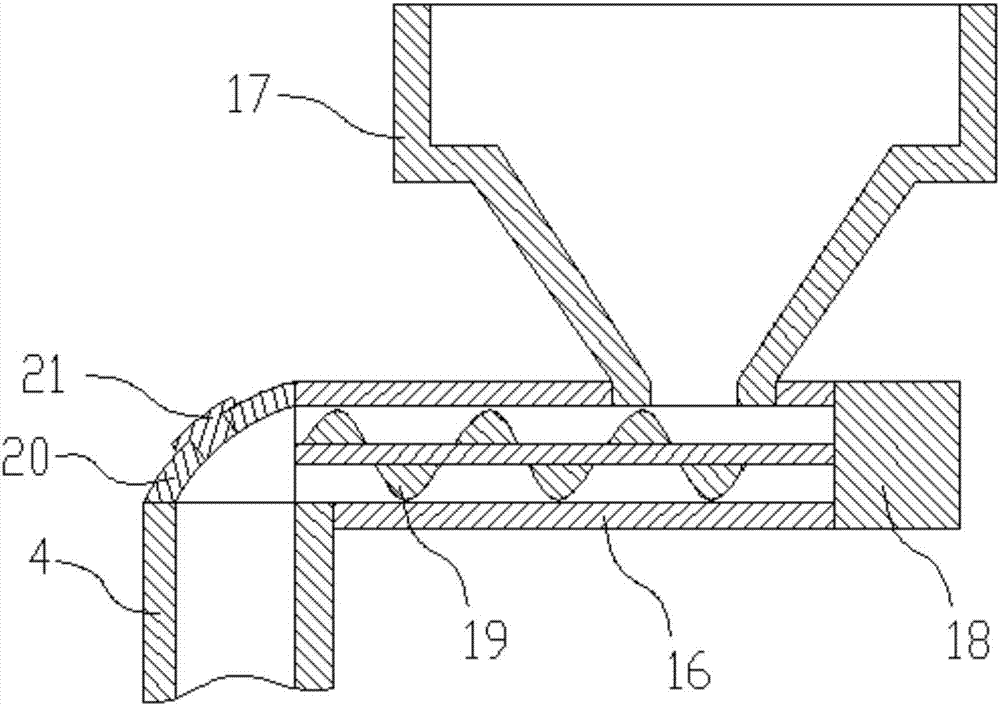

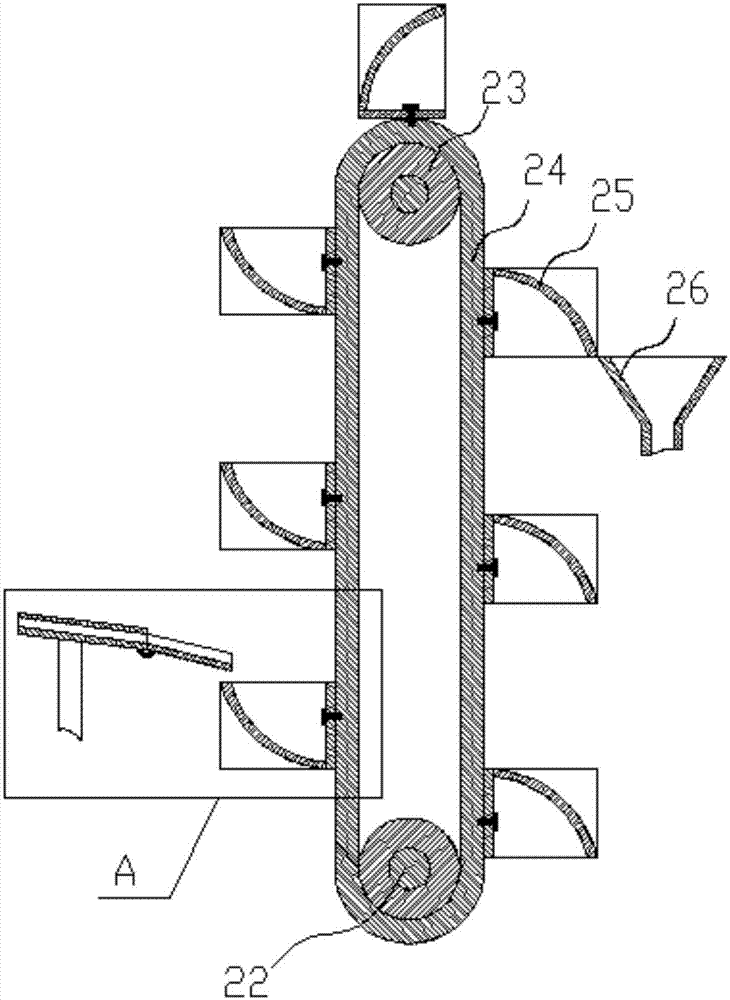

[0031] Such as Figure 1-Figure 4 As shown, the specific structure of the present invention is: a mica paper thermal dryer using new energy sources, which includes a frame 1, a washing tank 2 is provided on the frame 1, and the bottom of one end of the washing tank 2 A water inlet pipe 3 is connected, and a feeding pipe 5 is fitted above the washing tank 2. A side of the feeding pipe 5 close to the water inlet pipe 3 is provided with an inclined material lifting cylinder 5, and the lifting cylinder 5 The bottom is penetrated into the washing tank 2, the lifting cylinder 5 is provided with a lifting auger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com