Natural rubber production raw material processing method

A technology for natural rubber and processing methods, applied in separation methods, chemical instruments and methods, fixed filter element filters, etc., can solve the problems of slow artificial thinning and creping, latex rupture, latex bulging, etc., and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

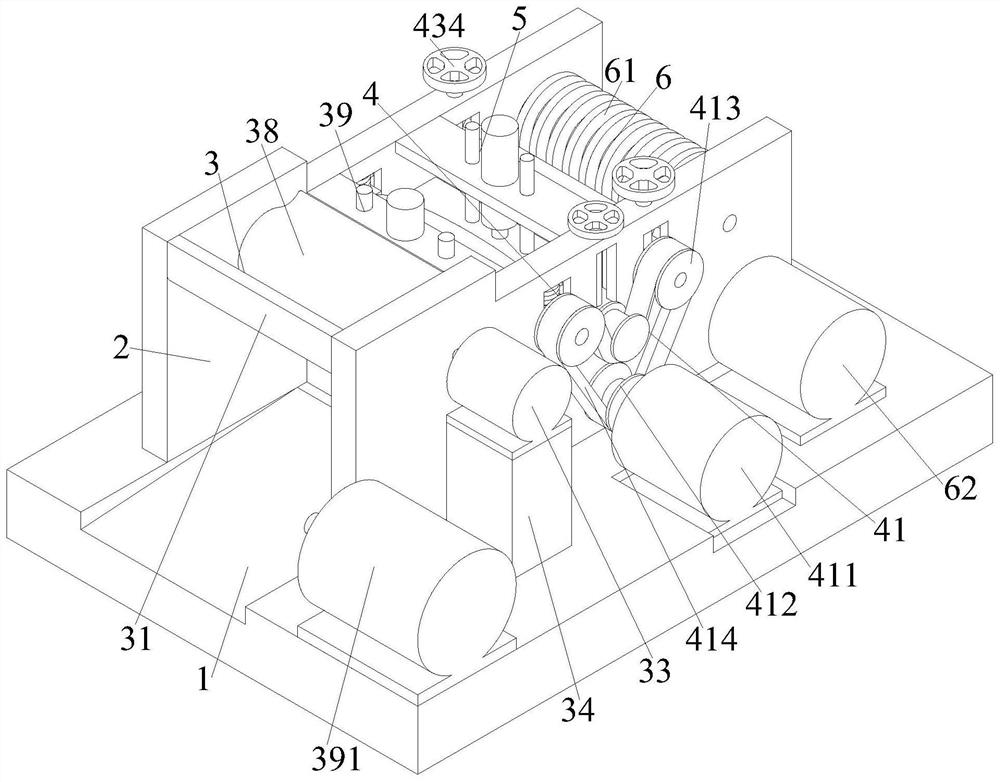

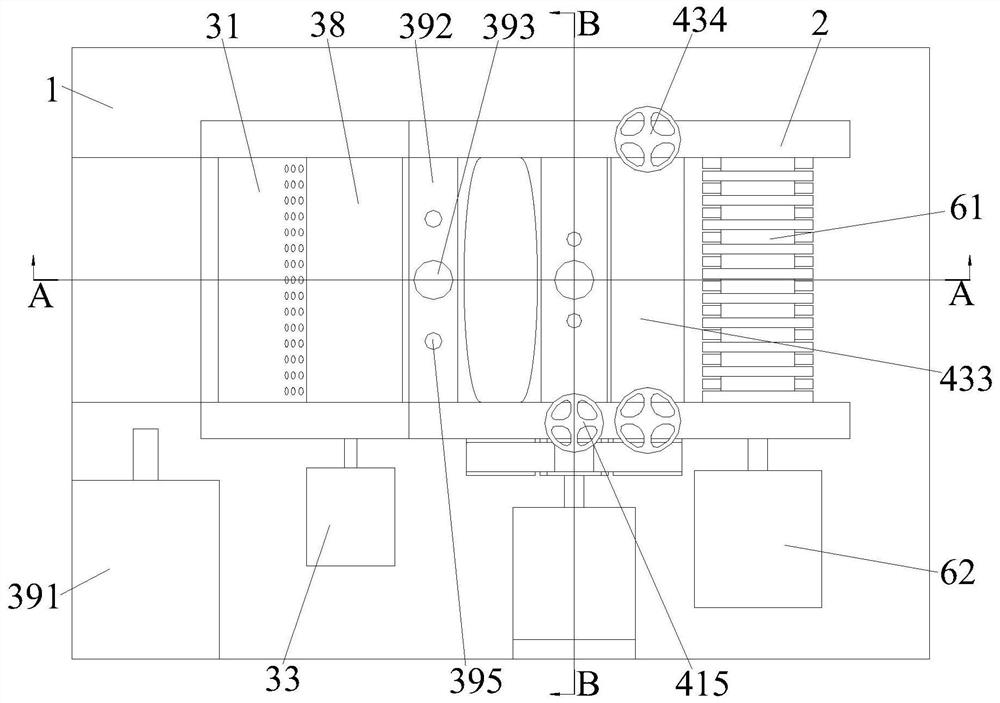

[0043] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

[0044] A method for processing raw materials for natural rubber production, which uses a raw material processing equipment for natural rubber production, the raw material processing equipment for natural rubber production includes a bottom plate 1, a side plate 2, a feeding device 3, a thinning device 4, and a piercing device 5 And creasing device 6, when adopting above-mentioned natural rubber production raw material processing equipment to produce and process natural rubber production raw material, concrete method is as follows:

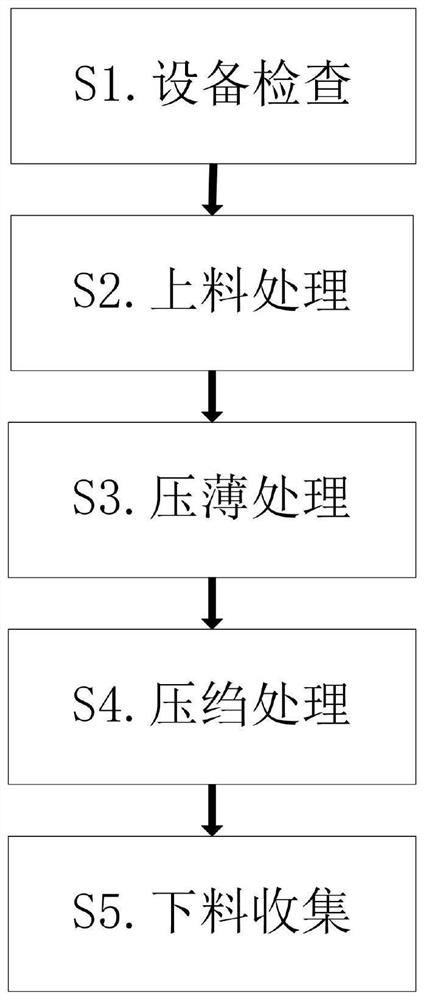

[0045] S1. Equipment inspection: before using natural rubber raw material processing equipment to produce and process natural rubber, inspect it;

[0046] S2. Feeding treatment: after the equipment inspection is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com