Setting technology of second-phase pre-stressed tendons in straddle type single-traffic-track girder bridge

A straddle-type monorail and prestressed tendon technology, applied in bridge construction, bridges, erection/assembly of bridges, etc., can solve the problems of many times of tension, cracking, affecting the durability of the structure, etc., so as to shorten the construction period and improve the durability. Sexual, obvious economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

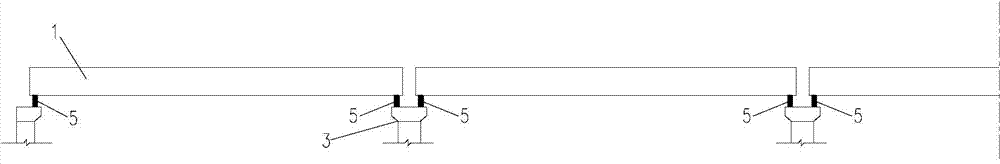

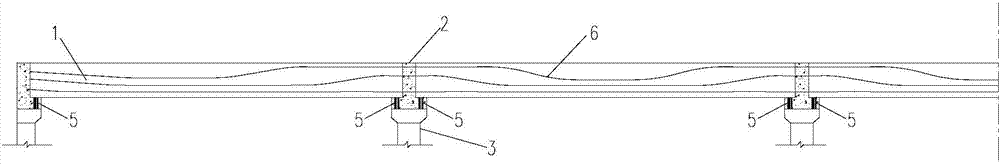

[0023] Embodiment 1 Setting of prestressed tendons in the second stage of track beam bridge with simply supported variable rigid frame system

[0024] For a 5×24m straddle-type monorail transit simply supported variable rigid frame system, a full-length curved second-stage prestressed tendon is set in the track girder bridge after system conversion, and the second-stage prestress is applied. The length of the track girder bridge is 120m, and the number of spans N is 5; the span of the prefabricated track girder is 23.2m; The number of prestressed tendons arranged in the negative bending moment area of the joint is 20, and the specification of the prestressed tendons is 7Φ5 steel strands; The number of stress tendons is 10, and the specification of prestress tendons is 7Φ5 steel strands; the length of wet joints is 0.8m.

[0025] Step 1 Hoist the prefabricated track girder onto the pier, and use the linear adjustment device for spatial positioning

[0026] The track girder ...

Embodiment 2

[0030] Embodiment 2 Setting of prestressed tendons in the second phase of simply supported variable continuous rigid frame track beam bridge

[0031] For a 5×24m straddle-type monorail transit simple-support variable continuous rigid frame system, a full-length curved second-stage prestressed tendon is set in the track girder bridge after system conversion, and the second-stage prestress is applied. The length of the track girder bridge is 120m, and the number of spans N is 5; the span of the prefabricated track girder is 23.2m; The number of prestressed tendons arranged in the negative bending moment area of the joint is 20, and the specification of the prestressed tendons is 7Φ5 steel strands; The number of stress tendons is 10, and the specification of prestress tendons is 7Φ5 steel strands; the length of wet joints is 0.8m.

[0032] Step 1 Hoist the prefabricated track girder onto the pier, and use the linear adjustment device for spatial positioning

[0033] The track...

Embodiment 3

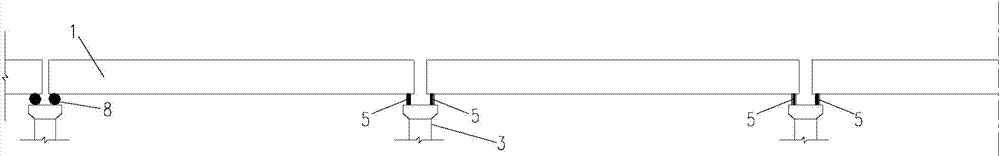

[0037] Embodiment 3 Setting of prestressed tendons in the second phase of simply supported variable continuous system track girder bridge

[0038] For a 5×24m straddle-type monorail transit simply supported variable continuous system, a full-length curved second-stage prestressed tendon is set in the track girder bridge after system conversion, and the second-stage prestress is applied. The length of the track girder bridge is 120m, and the number of spans N is 5; the span of the prefabricated track girder is 23.2m; The number of prestressed tendons arranged in the negative bending moment area of the joint is 20, and the specification of the prestressed tendons is 7Φ5 steel strands; The number of stress tendons is 10, and the specification of prestress tendons is 7Φ5 steel strands; the length of wet joints is 0.8m.

[0039] Step 1 Hoist the prefabricated track girder onto the pier, and use the linear adjustment device for spatial positioning

[0040]The track girder is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com