Comprehensive bituminous-mixture low-temperature-performance detection device

A technology of asphalt mixture and low-temperature performance, which is applied in the direction of material inspection products, the use of stable tension/pressure test material strength, and measuring devices, which can solve the problem of high test cost, poor versatility, and detection results of asphalt mixture specimens Low accuracy and other issues, to achieve the effect of reducing stability, realizing functional diversification, and reducing parallel detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

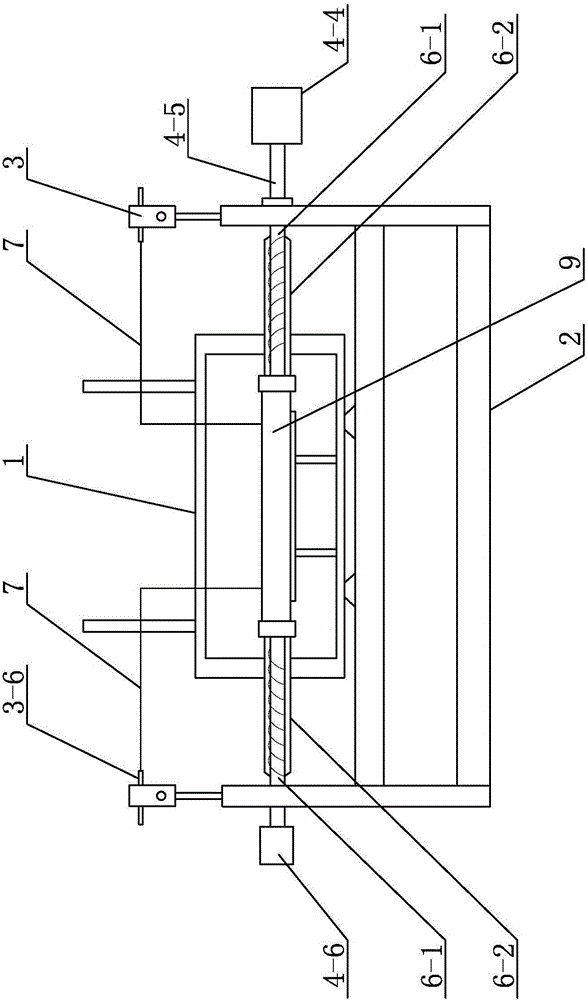

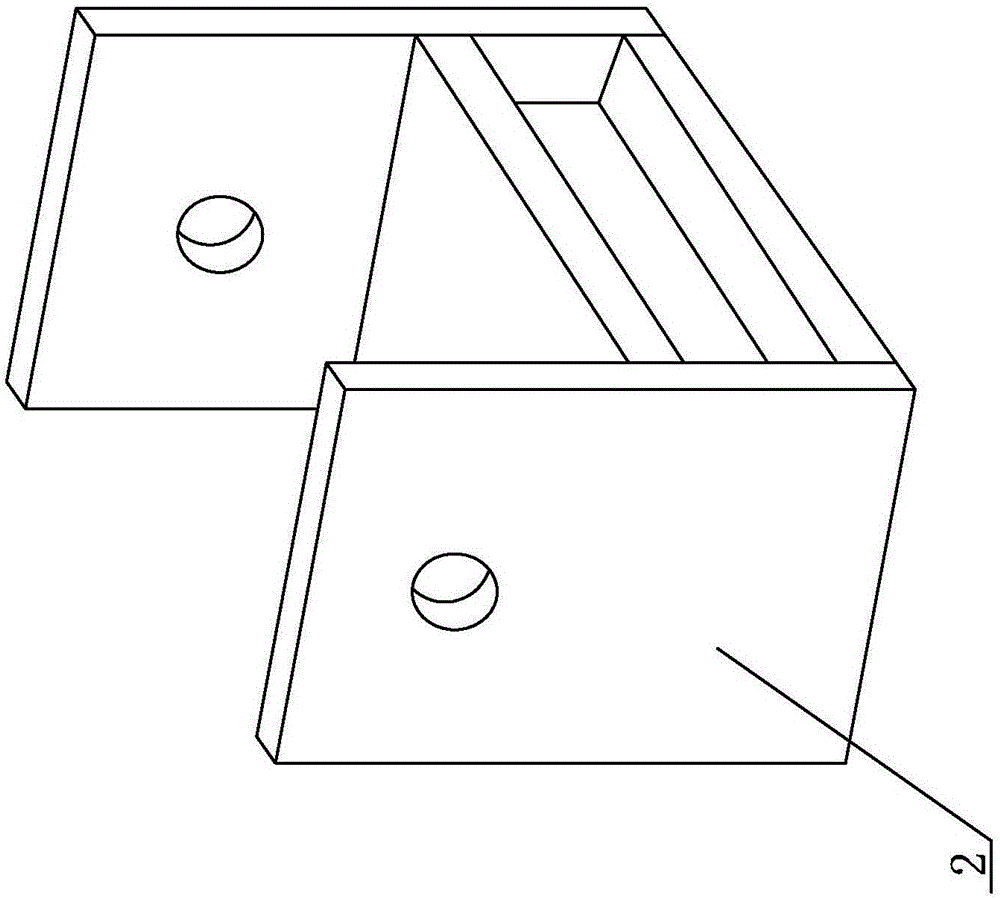

[0029] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment, this embodiment comprises environment box 1, counter force frame 2, displacement measurement system 3, data acquisition control system, microcosmic data acquisition system and heating system;

[0030] Described data acquisition control system comprises PC machine 4-1, controller acquisition card 4-2, motor driver 4-3, motor 4-4, transmission device 4-5 and stress sensor 4-6, PC machine 4-1 The controller acquisition card 4-2 is electrically connected to the motor driver 4-3, the motor driver 4-3 is electrically connected to the motor 4-4, and the motor 4-4 is connected to the asphalt mixture sample through the transmission device 4-5 9 phases are connected, and the controller acquisition card 4-2 is connected with the asphalt mixture test piece 9 through the stress sensor 4-6;

[0031] The microscopic data acquisition system includes a digital speckle ca...

specific Embodiment approach 2

[0037] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the displacement measurement system 3 in this embodiment includes a base 3-1, a total transverse support 3-2, two vertical supports 3-3, two sub-horizontal supports 3-4, two steering knuckles 3-5 and two LVDT rebound position sensors 3-6, the two vertical supports 3-3 are vertically arranged side by side on the base 3-1, and each vertical support 3-3 passes through the base 3-1 It is fixedly connected with the reaction force frame 2, and the total horizontal support 3-2 is horizontally arranged on two vertical supports 3-3 and is respectively slidably matched with each vertical support 3-3, and the two ends of the total horizontal support 3-2 Each is connected to a sub-transverse support 3-4 through a steering knuckle 3-5, and each sub-transverse support 3-4 is provided with an LVDT rebound type position sensor 3-6, and each LVDT rebound type position sensor 3 The probe of -...

specific Embodiment approach 3

[0041] Specific implementation mode three: combination figure 1 , figure 2 and Figure 4 This embodiment is described. In this embodiment, the motor 4-4 is a stepping motor, and the stress sensor 4-6 is a tension and compression stress sensor. In this embodiment, no vibration occurs during the test process through the setting of the stepping motor, and the impact on the test accuracy caused by the vibration of the motor is minimized. Stress sensors 4-6 are tension and compression stress sensors that effectively improve test accuracy. Other unmentioned structures and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com