A method for directional compound extraction of tobacco endogenous aroma substances

A technology for compound extraction of essential aroma substances, applied in the field of tobacco, can solve the problems that the taste of reconstituted cut tobacco cannot be well satisfied, large-scale industrial production is difficult, and spices become single, etc. Fragrant, quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

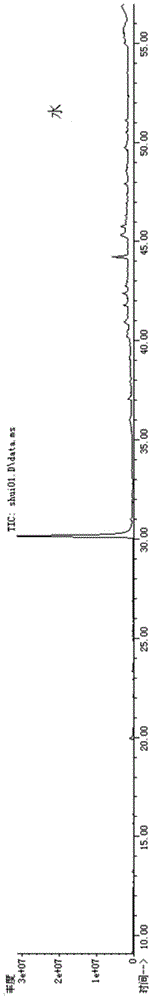

[0037] Take 40kg of waste soot and extract it with 280L of water at 40°C for 1 hour, filter, concentrate the extract to a density of 1.2g / mL, take 10,000g of water-extracted concentrate, and add it to 10kg of reconstituted tobacco leaf substrate as a control sample group.

Embodiment 2

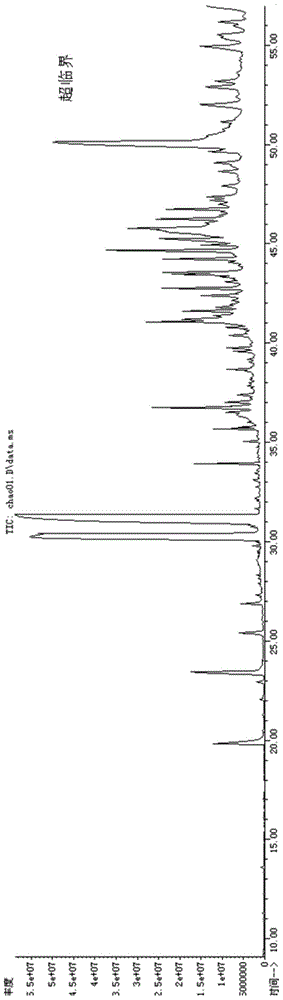

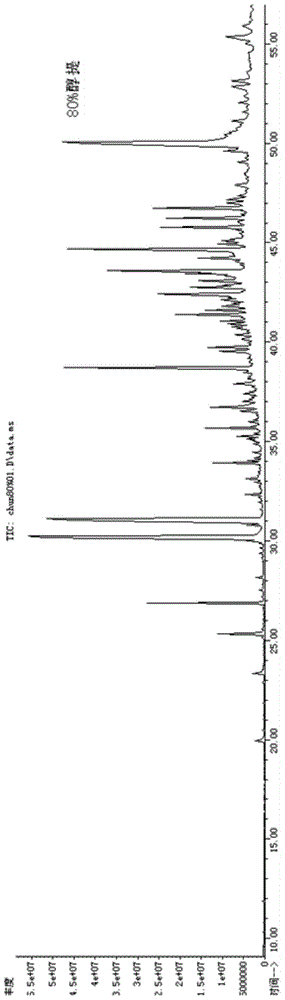

[0039] Take 40kg of waste soot, stir and extract with 200L water at 50°C for 1 hour, filter, concentrate the extract to a density of 1.2g / mL, and extract the concentrated solution with water for later use; 2 Carry out extraction, extraction condition is that extraction pot pressure is 25MPa, and extraction temperature is 40 ℃, CO 2 The flow rate is 200L / hour, and the extraction time is 4 hours; the pressure of the separation tank is 5 MPa, the separation temperature is 45°C, and 115g of extract is obtained after extraction; 10kg of waste soot is taken with 40L of 80% ethanol at 50°C, and the extraction time is 2 hours. Extracted twice, the extract was concentrated to a density of 1.2 g / mL; 2 30 g of extract and 200 g of ethanol extract concentrate were mixed evenly and added to 10 kg of reconstituted tobacco leaf base sheet. Through sensory evaluation, compared with the control sample group, the aroma texture and aroma volume were improved compared with the control sample grou...

Embodiment 3

[0041] Take 40kg of waste soot, stir and extract with 200L water at 40°C for 1 hour, extract twice, filter, concentrate the extract to a density of 1.1g / mL, and extract the concentrated solution with water for later use; take 6kg of waste and soot with supercritical CO 2 Carry out extraction, extraction condition is that extraction pot pressure is 20MPa, and extraction temperature is 35 ℃, CO 2 The flow rate is 180L / hour, and the extraction time is 3 hours; the pressure of the separation tank is 5.5 MPa, the separation temperature is 40°C, and 265g of extract is obtained after extraction; 10kg of waste soot is taken with 80L of 60% ethanol at 70°C, and the extraction time is 1 hour. Extract once, concentrate the extract to a density of 1.2 g / mL; take 10,000 g of the concentrated solution in water, 2 20 g of extraction and 150 g of ethanol extraction concentrate were mixed evenly and added to 10 kg of reconstituted tobacco leaf base sheet. Through sensory evaluation, compared w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com