Method for preparing polyol ester resin of terpene and rosin diene addition product based on rosin

A technology of rosin diene and polyol ester, which is applied in the field of polyol ester resin for preparing terpene and rosin diene adducts from rosin, can solve the problems such as no research report on polyol ester resin, and achieve the preparation method Energy saving, easy production operation, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

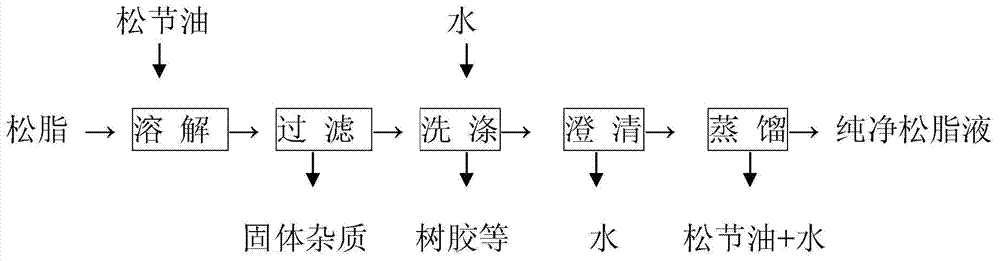

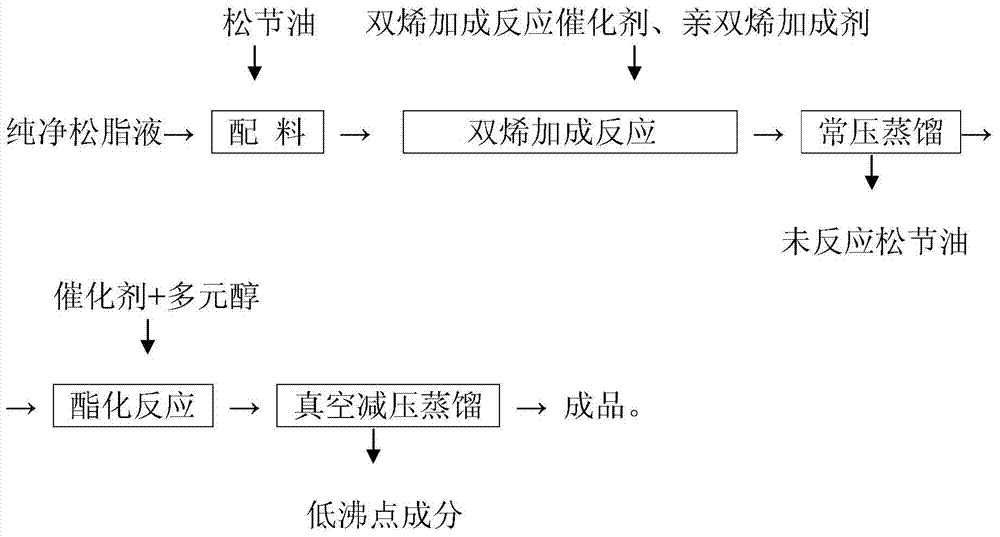

Method used

Image

Examples

Embodiment 1

[0040]In a 500ml four-necked flask with stirring, reflux, and distillation device functions, take 100 parts of net rosin liquid with a mass ratio of turpentine and rosin of 2:8, 60 parts of turpentine, and prepare a weight ratio of turpentine and rosin of 50 parts. : The reaction raw material A of 50. Add 55 parts of maleic anhydride and 1.6 parts of phosphoric acid, stir and heat to reflux reaction, control the reaction temperature, and gradually increase the temperature from 120°C to 190°C. When reflux occurs in the reaction, time the reaction for 2 hours, then steam the unreacted turpentine under normal pressure, then increase the reaction temperature to 210°C and continue the reaction for 1 hour, add 0.032 parts of zinc oxide, drop 50 parts of glycerin, and increase the reaction temperature to 220°C. -230°C, and control the reaction at 245-250°C for 3 hours, take a sample to measure the acid value, after passing the test (acid value is less than 40mgKOH / g), vacuum (20mmHg)...

Embodiment 2

[0042] In a 500ml four-neck flask with stirring, reflux, and distillation device functions, 120 parts of net turpentine liquid and 40 parts of turpentine were weighed, and the weight ratio of turpentine and rosin was prepared as reaction raw material A of 64:96. Add 60 parts of maleic acid and 1.2 parts of phosphoric acid, stir and heat to reflux reaction, control the reaction temperature, and gradually increase the temperature from 120°C to 200°C. When reflux occurs, time the reaction for 2 hours, then steam the unreacted turpentine under normal pressure, then increase the reaction temperature to 210°C and continue the reaction for 1 hour, add 0.04 parts of zinc oxide, drop 50 parts of glycerin, and increase the reaction temperature to 220- 230°C, and control the reaction at 250-260°C for 4 hours, take a sample to measure the acid value, after passing the test (acid value is less than 40mgKOH / g), vacuum (20mmHg) decompression, the temperature of the reaction bottle is controll...

Embodiment 3

[0044] In a 500ml four-necked flask with stirring, reflux, and distillation device functions, 150 parts of net turpentine liquid and 10 parts of turpentine were weighed, and the weight ratio of turpentine and rosin was prepared as reaction raw material A of 40:120. Add 40 parts of maleic anhydride and 0.8 parts of phosphoric acid, stir and heat to reflux reaction, control the reaction temperature, and gradually increase the temperature from 120°C to 210°C. When reflux occurs, the reaction time is 2 hours, and then the unreacted turpentine is steamed out under normal pressure, and then the reaction is continued at 210°C for 1 hour, 0.048 parts of zinc oxide is added, 60 parts of glycerin is added dropwise, and the reaction temperature is increased to 220-230°C. And control the reaction at 245-250°C for 3 hours, take a sample to measure the acid value, after passing the test (acid value is less than 40mgKOH / g), vacuum (20mmHg) depressurization, control the temperature of the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com