Fiber-reinforced ABS material and preparation method thereof

An ABS material and fiber reinforced technology, applied in the field of fiber reinforced ABS material and its preparation, can solve the problems of low strength, insufficient surface hardness, low impact, etc., and achieve good dimensional stability, low warpage, and meet individual consumer needs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

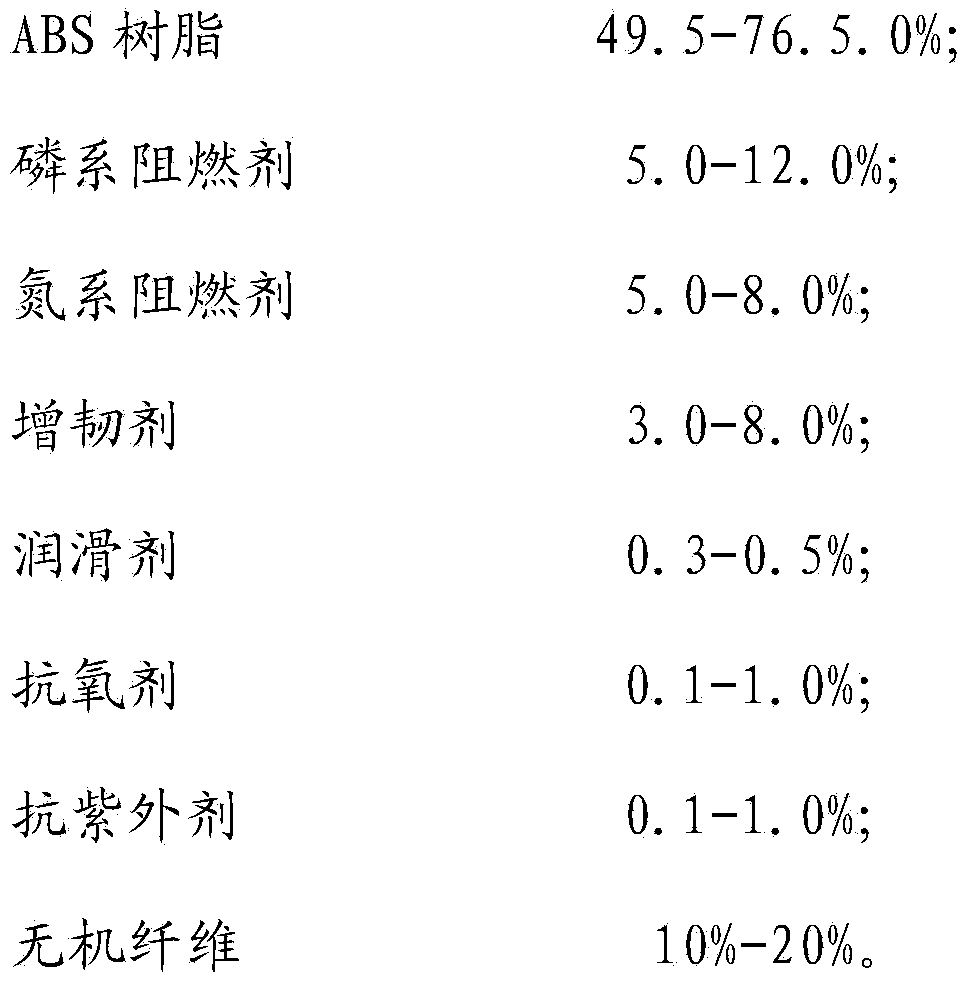

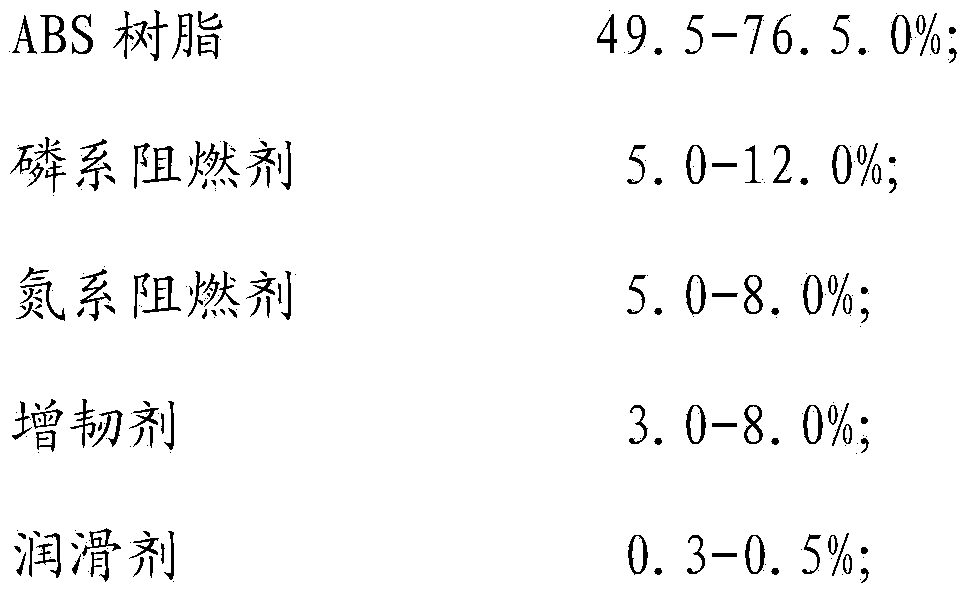

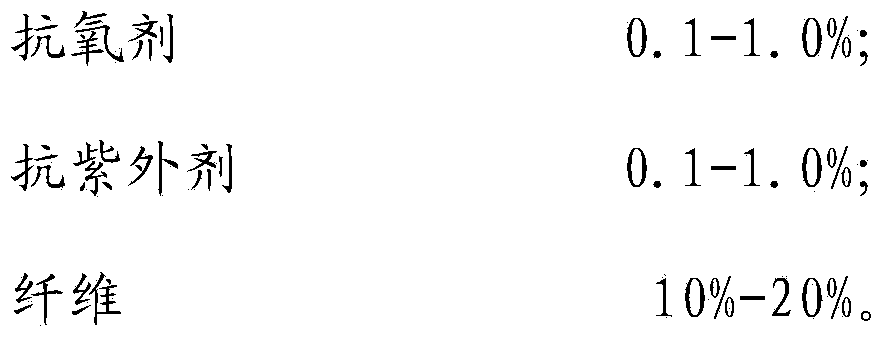

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of fiber reinforced ABS material of the present invention comprises the following steps:

[0038] 1) Weigh the materials according to the ratio;

[0039] 2) Pour the materials except fibers into the mixing tank and stir for 5-10 minutes at a stirring speed of 300-450 rpm to mix the materials;

[0040] 3) Treat the glass fiber with a coupling agent and dry it:

[0041] 4) Put the mixed raw materials into the twin-screw extruder for melt extrusion and granulation. By increasing the side feed port, the fibers are added through the side feed port. The processing technology is as follows: the first zone of the twin-screw extruder 200- 210℃, 215-220℃ in the second zone, 215-220℃ in the third zone, 215-220℃ in the fourth zone, 220-230℃ in the fifth zone, 225-230℃ in the sixth zone, 220-225℃ in the seventh zone, 215-220 in the eighth zone ℃; screw speed 300-450 rpm.

Embodiment 1

[0043] Stir the weight ratio of ABS63.0%, toluene xylyl phosphate 10.0%, MPP3.0%, toughening agent HR1816.0%, lubricant 0.5%, antioxidant 1.0%, anti-ultraviolet agent 0.5% in the mixing tank After 5 minutes, the twin-screw extruder is melted and extruded to make granules, and the pre-treated glass fiber is added from the feeding port. Its processing technology is as follows: Twin-screw extruder one zone 200-210°C, two zone 215-220°C, three zone 215-220°C, fourth zone 215-220°C, five zone 220-230°C, six zone 225-230°C ℃, seven zone 220-225 ℃, eight zone 215-220 ℃; screw speed 300-450 rpm. Combining RHCM injection molding process to realize 50-inch ultra-thin, ultra-light, narrow-edge LCD TV frame, the production of products achieves reflective effect, no deformation and warping, surface hardness reaches H, and flame retardancy reaches UL94V0.

[0044]

Embodiment 2

[0046] Stir the weight ratio of ABS63.0%, toluene xylyl phosphate 10.0%, MPP3.0%, toughening agent HR1816.0%, lubricant 0.5%, antioxidant 1.0%, anti-ultraviolet agent 0.5% in the mixing tank After 5 minutes, the twin-screw extruder is melted and extruded to make granules, and the pre-treated glass fiber is added from the feeding port. The processing technology is as follows: Zone 1 200-210℃, zone 2 215-220℃, zone 3 215-220℃, zone 4 215-220℃, zone 5 220-230℃, zone 6 225-230℃, zone 7 220 -225°C, eight zones 215-220°C; screw speed 300-450 rpm. Combining RHCM injection molding process to realize 50-inch ultra-thin, ultra-light, narrow-edge LCD TV frame, the production of products achieves reflective effect, without any deformation and warping, and the surface hardness reaches 2H.

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com