Method for preparing PTC (positive temperature coefficient) material by compounding polyaniline/carbon black/polyolefin

A polyaniline and polyolefin technology is applied in the field of preparing self-limiting temperature conductive functional materials, which can solve the problems of limiting the industrial application of conductive composite materials, lack of large-scale production, high cost, etc., and achieve uniform particle size distribution and improved compatibility. performance, dust reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

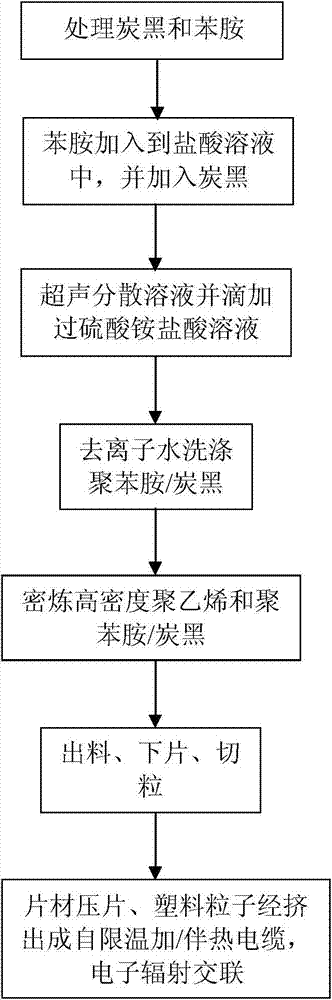

Image

Examples

Embodiment 1

[0034] Step 1: process carbon black and aniline, place carbon black in a vacuum oven and dry to constant weight at a drying temperature of 50°C, and process aniline by vacuum distillation;

[0035] Step 2: Add aniline to the hydrochloric acid solution, and add carbon black, the ratio of aniline monomer to carbon black is 5:1;

[0036] Step 3: ultrasonically disperse the solution formed in step 2, and slowly add ammonium persulfate hydrochloric acid solution dropwise to the solution under mechanical stirring;

[0037] Step 4: Repeatedly washing the polyaniline / carbon black product generated in the suction filtration step 3 with deionized water;

[0038] Step 5: Mix the high-density polyethylene and the polyaniline / carbon black produced in Step 4 in a proportion of 100:25 in a banbury mixer evenly, and the banbury temperature is 150°C;

[0039] Step 6: Discharge, slice, and pelletize the product generated in step 5;

[0040] Step 7: Press the sheet formed in Step 6 on a flat v...

Embodiment 2

[0042] Step 1: process carbon black and aniline, place carbon black in a vacuum oven and dry to constant weight at a drying temperature of 50°C, and process aniline by vacuum distillation;

[0043] Step 2: Add aniline to the hydrochloric acid solution, and add carbon black, the ratio of aniline monomer to carbon black is 10:3;

[0044] Step 3: ultrasonically disperse the solution formed in step 2, and slowly add ammonium persulfate hydrochloric acid solution dropwise to the solution under mechanical stirring;

[0045] Step 4: Repeatedly washing the polyaniline / carbon black product generated in the suction filtration step 3 with deionized water;

[0046] Step 5: Mix the high-density polyethylene and the polyaniline / carbon black produced in Step 4 according to the ratio of 100:27 in the banbury mixer evenly, and the banbury temperature is 150°C;

[0047] Step 6: Discharge, slice, and pelletize the product generated in step 5;

[0048] Step 7: Press the sheet formed in step 6 o...

Embodiment 3

[0050] Step 1: process carbon black and aniline, place carbon black in a vacuum oven and dry to constant weight at a drying temperature of 50°C, and process aniline by vacuum distillation;

[0051] Step 2: Add aniline to the hydrochloric acid solution, and add carbon black, the ratio of aniline monomer to carbon black is 5:1;

[0052] Step 3: ultrasonically disperse the solution formed in step 2, and slowly add ammonium persulfate hydrochloric acid solution dropwise to the solution under mechanical stirring;

[0053] Step 4: Repeatedly washing the polyaniline / carbon black product generated in the suction filtration step 3 with deionized water;

[0054] Step 5: Mix high-density polyethylene and polyaniline / carbon black produced in Step 4 in a proportion of 100:27 in a banbury mixer evenly, and the banbury temperature is 150°C;

[0055] Step 6: Discharge, slice, and pelletize the product generated in step 5;

[0056] Step 7: Press the sheet formed in Step 6 on a flat vulcaniza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com