Recycling method of thermosetting resin lens waste

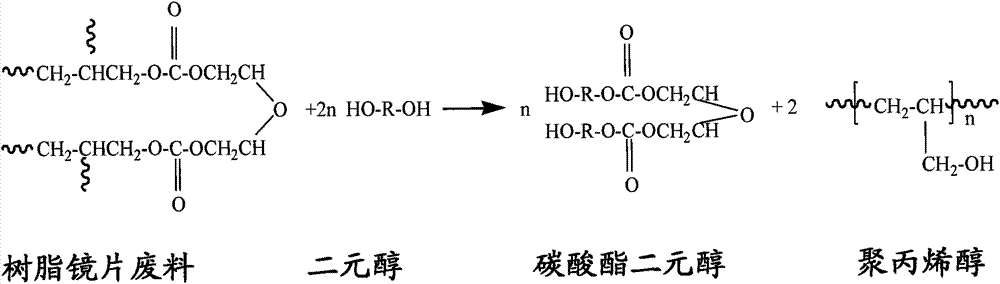

A resin lens and thermosetting technology, applied in the field of alcoholysis recycling of thermosetting resin lenses, can solve the problems of polluting the environment, waste of resources, etc., and achieve the effect of high utilization value, less consumption, and overcoming secondary waste discharge and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Take 100 parts of resin lens waste sheet powder, 200 parts of diethylene glycol, and 1 part of zinc acetate. Stir evenly and heat up to the reaction temperature. The temperature is controlled at 210-230° C., and the reaction time is 2.5-3 hours. The yield is 100%, and the product is a light yellow clear liquid with a viscosity of 225mPa·s.

Embodiment 2

[0043] Embodiment 2: Get 100 parts of resin lens waste sheet material powder, 180 parts of diethylene glycol, 1 part of zinc acetate, 0.6 part of sodium hydroxide, stir evenly and heat up to the reaction temperature, the temperature is controlled at 210-230 ° C, and the reaction time is 1 After ~1.5 hours, the alcoholysis rate is 100%, and the product is a dark yellow clear transparent liquid with a viscosity of 180mPa·s.

Embodiment 3

[0044] Example 3: Take 100 parts of resin lens waste grinding dust powder, 220 parts of diethylene glycol, 1 part of zinc chloride, and 1 part of sodium hydroxide, stir evenly and heat up to the reaction temperature. The temperature is controlled at 210-230 ° C. The reaction time After 2.0 to 2.5 hours, the alcoholysis rate is 100%, and the product is a brown clear liquid with a viscosity of 240mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com