Be and multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material and preparation method thereof

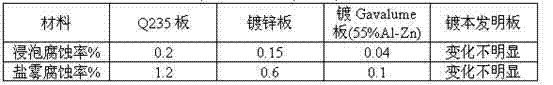

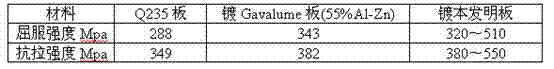

A technology of aluminum alloy and hot-dip plating, which is applied in the direction of hot-dip plating process, metal material coating process, coating, etc., which can solve the long-term development of the hot-dip plating industry, intergranular corrosion of the coating, and the limitation of steel plate cooling speed, etc. problems, to achieve the effect of improving cycle efficiency and reuse value, acid, alkali and salt corrosion resistance, and reducing environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

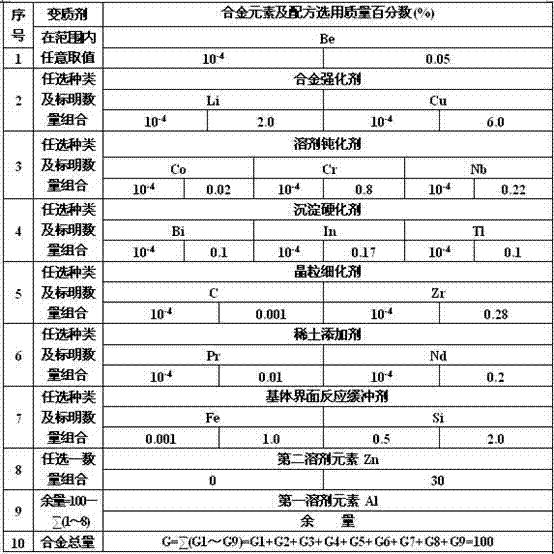

[0074] Example 1: Be-Cu-Cr-Bi-C-Pr-Si combination

[0075] (1) Select a group of elements according to the formula combination table, according to the percentage by weight: polarizing modifier Be: 0.05, alloy strengthening agent Cu: 6.0, solvent passivating agent Cr: 0.8, precipitation hardening agent Bi :0.1, grain refiner C :0.001, rare earth additive Pr : 0.01, substrate interface reaction buffer element Si: 2.0, the second solvent element Zn: 30, and the balance is Al; the total amount of alloy prepared is 1000kg, then the weight of each material required for derivation is: Be: 5kg, Cu: 60kg, Cr: 8kg, Bi : 1kg, C :0.01kg, Pr : 0.1kg, Si: 20kg, Zn: 300kg, Al: 605.89kg.

[0076] (2) First add aluminum ingots or molten aluminum into the melting furnace, heat it to melt it completely and keep it warm at 700-800°C;

[0077] (3) Add matrix interface reaction buffer, Be, solvent passivator, grain refiner, alloy strengthening agent, rare earth additive and precipitation ...

Embodiment 2

[0081] Example 2: Be-Li-Nb-Tl-Zr-Nd-Fe-Si combination

[0082] (1) Select a group of elements according to the formula combination table, according to the percentage by weight: Be: 10 -4 , alloy strengthener Li: 10 -4 , solvent passivator Nb:10 -4 , precipitation hardener Tl: 10 -4 , grain refiner Zr:10 -4 , rare earth additive: Nd: 10 -4, the matrix interface reaction buffer element Fe: 0.001, Si: 0.5, the second solvent element Zn: 1, the balance is Al; the total amount of the prepared alloy is 1000kg, then the weight of each material required is calculated as: Be: 0.001kg, Li: 0.001kg, Nb: 0.001kg, Tl: 0.001kg, Zr: 0.001kg, Nd: 0.001kg, Fe: 0.01kg, Si: 5kg, Zn: 10kg, Al: 984.984kg.

[0083] All the other steps are the same as in Example 1.

Embodiment 3

[0085] (1) Select a group of elements according to the formula combination table, according to the percentage by weight: Be: 0.01, alloy strengthening agent Cu: 4.0, Li: 2.0, solvent passivator Co: 0.02, Cr: 0.8, Nb: 0.18, Precipitation hardener Bi: 0.1, In: 0.17, Tl: 0.1, grain refiner C: 0.001, Zr: 0.28, rare earth additive Pr: 0.01, Nd: 0.2, matrix interface reaction buffer element Fe: 1.0, Si: 1.0 , the second solvent element Zn: 10, the balance is Al; the total amount of the prepared alloy is 1000kg, then the weight of each substance required is calculated as Be: 0.1kg, Cu: 40kg, Li: 20 kg, Co: 0.2kg, Cr: 8kg, Nb: 1.8kg, Bi: 1kg, In: 1.7kg, Tl: 1kg, C: 0.01kg, Zr: 2.8kg, Pr: 0.1kg, Nd: 2kg, Fe: 10kg, Si: 10kg, Zn: 100kg, Al: 801.29kg.

[0086] All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com