Solid fuel pneumatic conveying heating method and system capable of controlling content of ash combustible

A solid fuel, pneumatic conveying technology, applied in the direction of energy input, petroleum industry, coke oven, etc., can solve the problem of inability to control the content of combustibles well, and achieve the effect of improving the reuse value and scientific method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

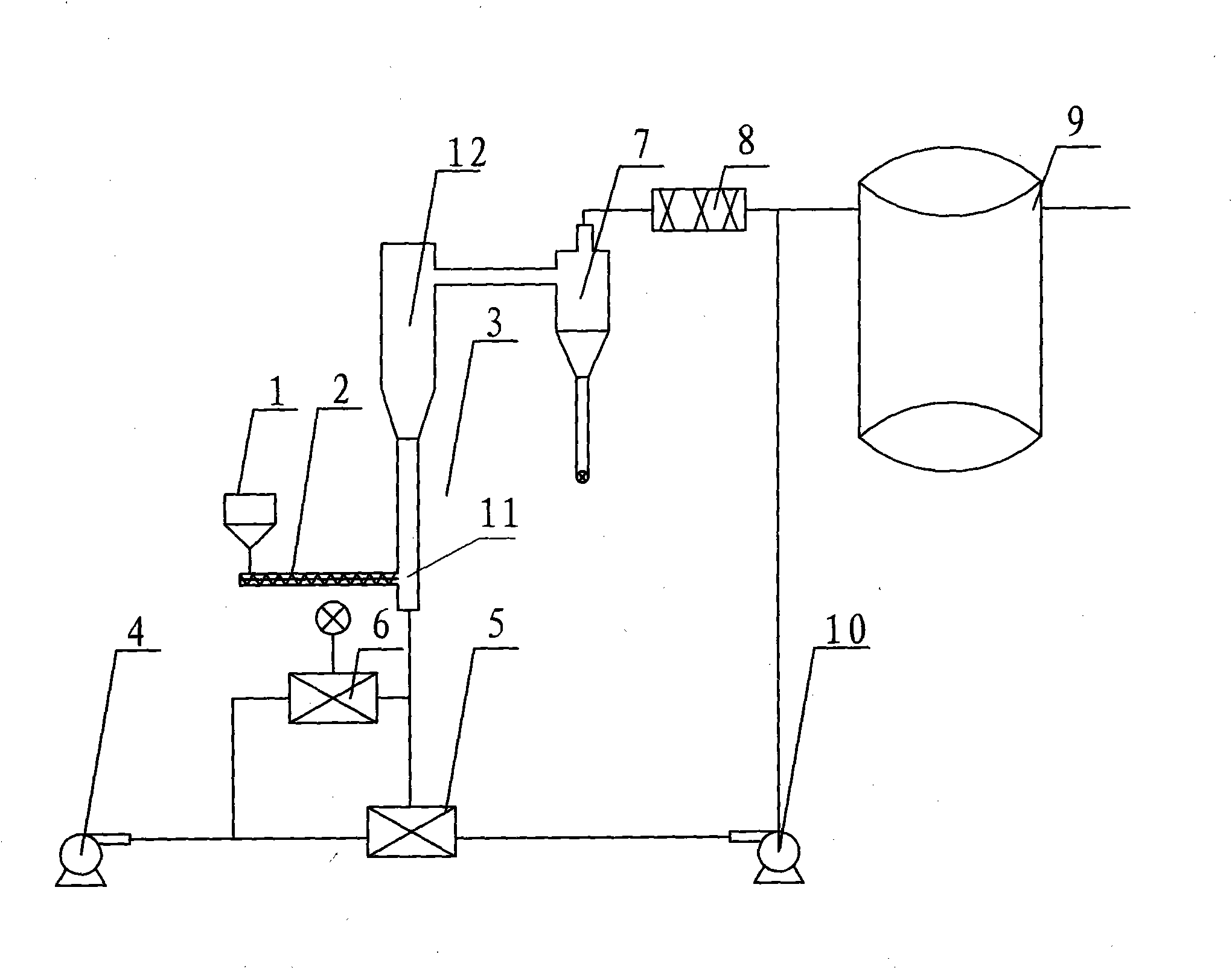

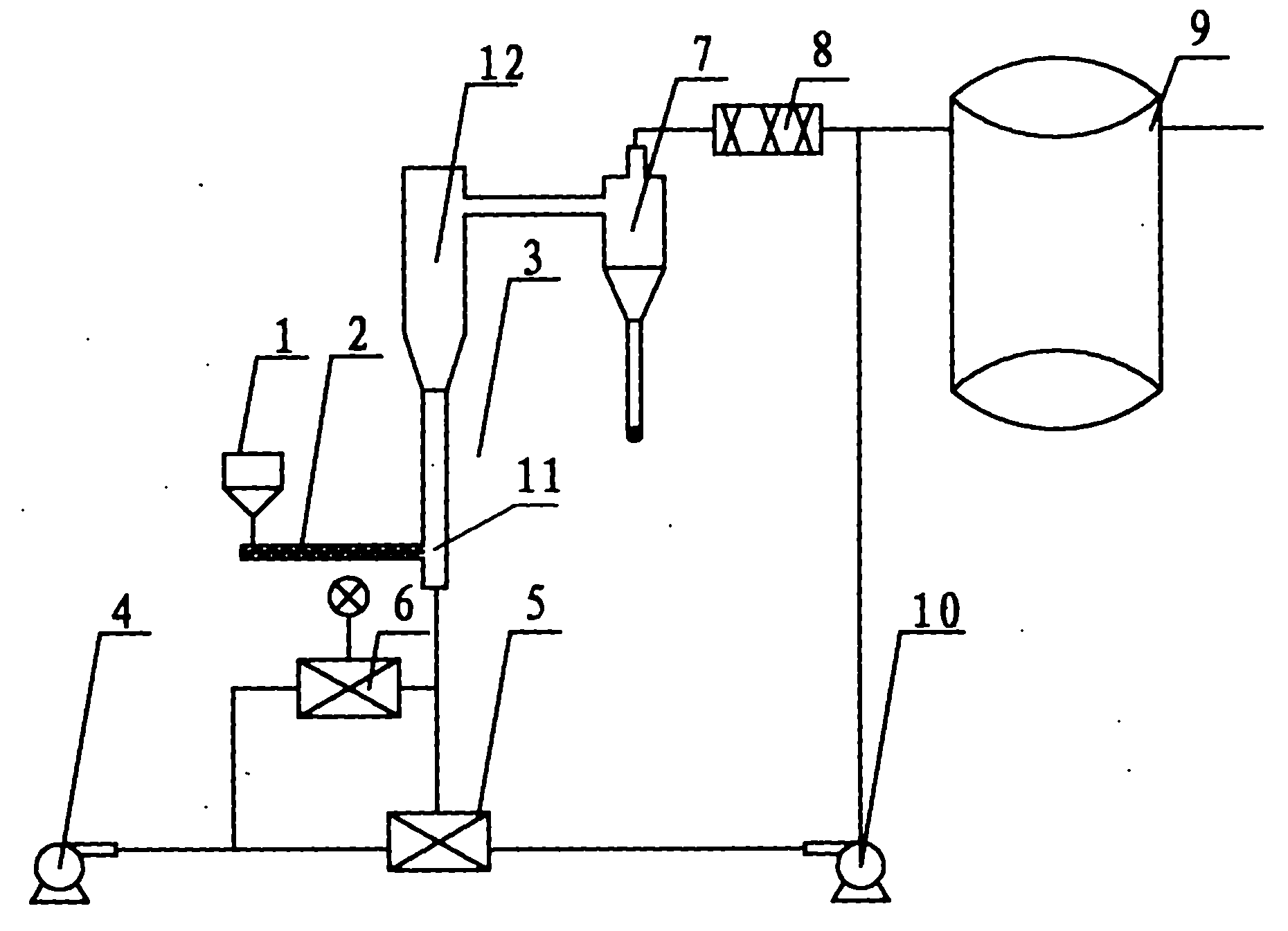

[0013] The present invention will be further described below using the drawings and specific embodiments.

[0014] Referring to the figure, the solid fuel pneumatic conveying temperature raising method for controlling the content of ash and slag combustibles of the present invention, at room temperature, the solid fuel has a calorific value of 17540kJ / kg, a volatile matter of 11.7%, and a fixed carbon of 43.4%. The particles are sent from the feed hopper 1 to the screw coal feeder 2, and are transported to the conveying section 11 of the spouted bed burner 3 through the screw feeder 2; Combustion in the generator 6 produces flue gas with a pressure of 3000-8000pa and a temperature of 400-1000°C, which is sent to the delivery section 11 of the spouted bed burner 3, and after the spouted bed burner 3 burns stably, the flue gas mixer 5 is closed , the air at room temperature and the flue gas at 600-800°C are sent to the flue gas mixer 5 by the blower 4, and the oxygen content of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com