Austenite stainless steel lap-over laser welding method

An austenitic stainless steel, laser welding technology, used in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problem that the resistance spot welded car body cannot meet the requirements of high-quality stainless steel rail passenger car production, and affects non-ferrous metals. The appearance quality of the painted stainless steel car body is not suitable for high-speed EMUs, etc., so as to improve the driving safety, reduce the deformation, and improve the mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

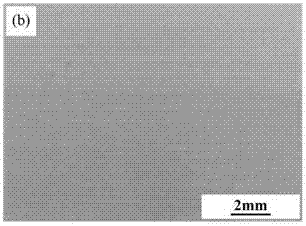

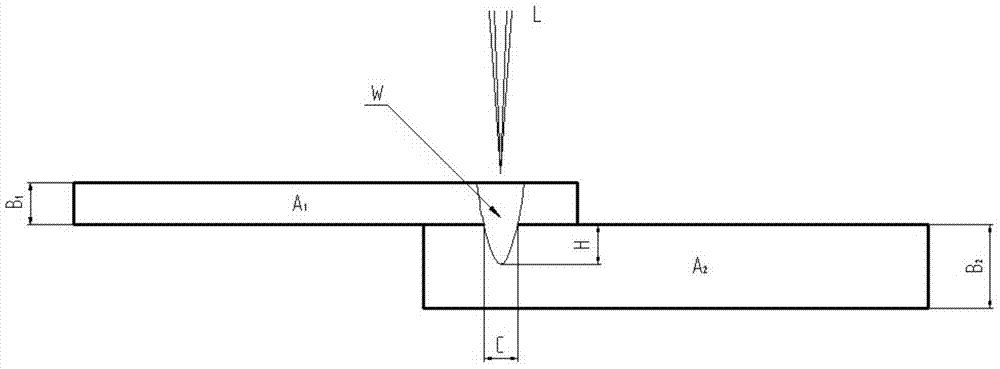

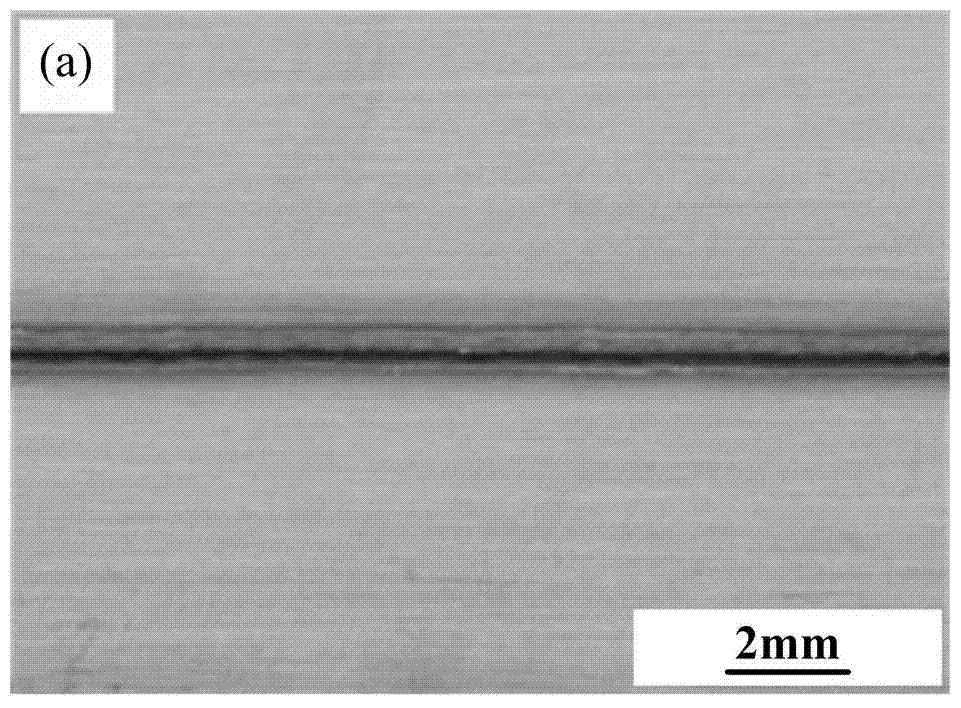

[0025] Embodiment 1. SUS301L austenitic stainless steel overlap laser welding connection is carried out by adopting the technology of the present invention, and the combination of stainless steel plate thickness is 1+2mm (the thickness of the upper plate is 1mm, and the thickness of the lower plate is 2mm). Before welding, put the pure copper backing plate in the tire fixture, and then place the stainless steel plate on the backing plate to clamp; the laser welding parameters are: laser power 1.9kW, defocus -0.5, welding speed 21mm / s ; After welding, the joint has no welding defects such as cracks, pores, lack of fusion, undercut, etc.; the melting width at the interface between the upper plate and the lower plate of the lap joint is 0.86mm, and the melting depth of the lower plate is 0.43mm; the tensile shear load of the joint is 24.3kN, and the joint The fatigue strength is 122.3MPa; there are no welding traces and oxidative discoloration on the back of the weld.

Embodiment 2

[0026] Embodiment 2: SUS301L austenitic stainless steel overlap laser welding connection is carried out by adopting the technology of the present invention, and the combination of stainless steel plate thickness is 1+2mm (the thickness of the upper plate is 1mm, and the thickness of the lower plate is 2mm). Before welding, put the pure copper backing plate in the tire fixture, and then place the stainless steel plate on the backing plate to clamp; the laser welding parameters are: laser power 2.0kW, defocus amount 1.0, welding speed 22mm / s; After welding, the joint has no welding defects such as cracks, pores, lack of fusion, and undercut; the melting width at the interface between the upper plate and the lower plate of the lap joint is 0.80mm, and the melting depth of the lower plate is 0.41mm; the tensile shear load of the joint is 24.1kN, and the joint is fatigued. The strength is 118.3MPa; there are no welding traces and oxidative discoloration on the back of the weld.

Embodiment 3

[0027] Embodiment 3. The technology of the present invention is used to carry out lap joint laser welding of SUS301L austenitic stainless steel, and the combination of stainless steel plate thickness is 1+2 mm (the thickness of the upper plate is 1 mm, and the thickness of the lower plate is 2 mm). Before welding, put the pure copper backing plate in the tire fixture, and then place the stainless steel plate on the backing plate to clamp; the laser welding parameters are: laser power 2.1kW, defocus amount 0.5, welding speed 23mm / s; After welding, the joint has no welding defects such as cracks, pores, lack of fusion, and undercut; the melting width at the interface between the upper plate and the lower plate of the lap joint is 0.72mm, and the melting depth of the lower plate is 0.35mm; the tensile shear load of the joint is 22.9kN, and the joint is fatigued. The strength is 111.7MPa; there are no welding traces and oxidative discoloration on the back of the weld.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com