Arched composite alloy protection plate module and production technology thereof

A composite alloy and production process technology, which is applied in the arch composite alloy guard plate module and its production process, and the bottom protection field of wheeled armored vehicles. It can solve the problems of inconvenient disassembly and maintenance, affecting vehicle driving, and difficult production process. Achieve the effect of saving materials, reducing maintenance costs and improving explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

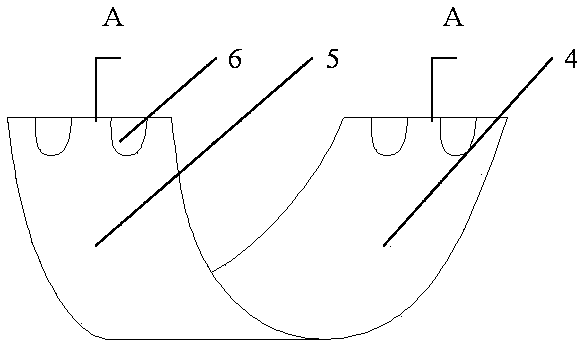

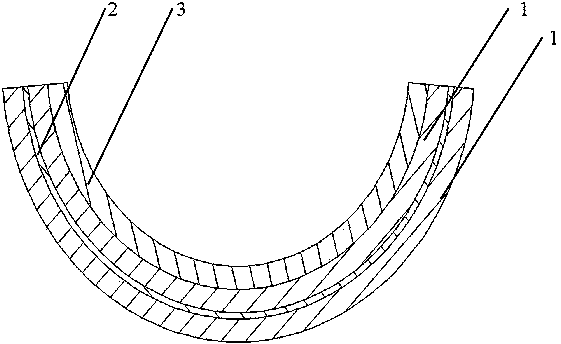

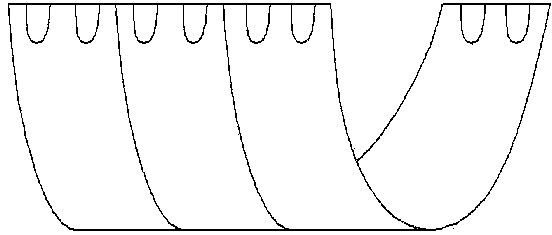

[0048] The arched composite alloy shield module of the present invention is composed of a metal matrix 1 and a metal mesh 2, and the metal mesh 2 is compounded in the metal matrix 1, about one-third from the outer surface 5 of the shield module. The fiber composite lining board 3 bonded to the inner surface of the metal matrix is made of glass fiber and phenolic resin. The inner lining of the guard plate pressed by glass fiber phenolic resin is composed of 11 layers of glass fiber cloth with a thickness of 0.5 mm, and the total thickness is 6 mm. The width of the composite alloy guard plate module is 1006mm, and the arc is 160 degrees. 4 is the inner surface of the guard plate module, and 6 is a screw hole, which is used to fix the guard plate module on the frame of the vehicle chassis.

[0049] The chemical composition and weight percentage of said metal matrix 1 are: C 0.25%, Cr 0.93%, Mo 0.5%, Si 0.45%, Mn 0.45%, V 0.05%, Cu 0.07%, Al 0.22%, Ti 0.05 %, Ni 0.55%, the res...

Embodiment 2

[0062] The arched composite alloy guard plate module of the present invention is composed of a metal matrix 1 and a metal mesh 2. The metal mesh 2 is compounded in the metal matrix 1 and is located about one-third from the outer surface 5 of the guard plate module. The fiber composite lining board 3 bonded to the inner surface of the metal matrix is made of refractory fiber and phenolic resin. The inner lining of the guard plate pressed by glass fiber phenolic resin is composed of 15 layers of glass fiber cloth with a thickness of 0.5mm, and the total thickness is 8mm. The width of the arched composite alloy guard plate is 1006mm, and the arc of the arch is 160 degrees. 4 is the inner surface of the guard plate module, and 6 is a screw hole, which is used to fix the guard plate module on the frame of the vehicle chassis.

[0063] The chemical composition and weight percentage of said metal matrix 1 are: C 0.08%, Cr 0.7%, Mo 0.3%, Si 0.35%, Mn 0.35%, V 0.03%, Cu 0.05%, Al 0.2...

Embodiment 3

[0068] The arched composite alloy guard plate module of the present invention is composed of a metal matrix 1 and a metal mesh 2. The metal mesh 2 is compounded in the metal matrix 1 and is located about one-third from the outer surface 5 of the guard plate module. The fiber composite lining board 3 bonded to the inner surface of the metal matrix is made of glass fiber and phenolic resin. The lining of the guard plate pressed by glass fiber phenolic resin is composed of 8 layers of glass fiber cloth with a thickness of 0.5mm, and the total thickness is 5mm. The width of the arched composite alloy guard plate is 1006mm, and the arc of the arch is 160 degrees. 4 is the inner surface of the guard plate module, and 6 is a screw hole, which is used to fix the guard plate module on the frame of the vehicle chassis.

[0069] The chemical composition and weight percentage of said metal matrix 1 are: C 0.3%, Cr 1.2%, Mo 0.8%, Si 0.60%, Mn 0.60%, V 0.07%, Cu 0.10%, Al 0.35%, Ti 0.08%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com