A kind of sealing process of led module

An LED module and process technology, applied in the parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of high sealing cost and poor effect, achieve low cost, reduce glue usage, The effect of good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

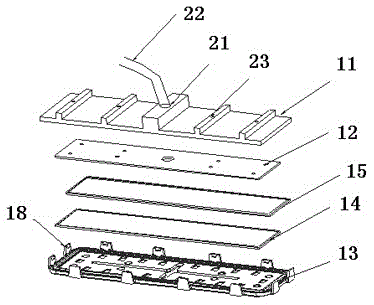

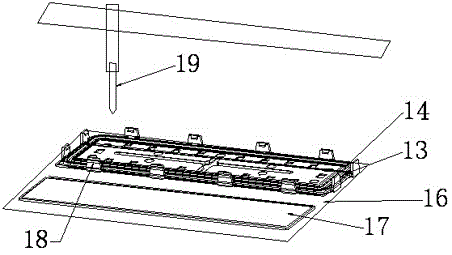

[0048] see Figure 1 to Figure 3, the technical solution adopted by a kind of LED sealing process is: a kind of LED illuminating device, comprises cooling rack 11, PCB board 12, LED chip, sealing silica gel and lens group 13, LED chip is welded on the PCB board 12, PCB board 12 and The cooling frame 11 is pasted together, and the lens group 13 is installed above the LED chip.

[0049] The cooling frame may include one lamp frame unit or multiple lamp frame units, and each lamp frame unit corresponds to a PCB board 12 , a lens group 13 and sealing silicone. The following takes a single light stand unit as an example:

[0050] The heat dissipation frame 11 can be cut from profiles, which not only plays the role of a light frame, but also acts as a heat sink. The processing process is simple and the cost is low. According to different needs, different shapes of profiles can be selected for the cooling frame.

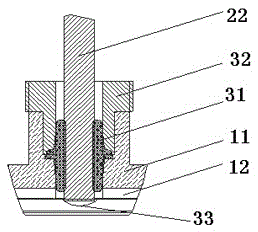

[0051] The cooling frame 11 is provided with a through hole 21 with...

Embodiment 2

[0074] The process steps of embodiment 2 are roughly the same as those of embodiment 1, except that the solid silicone ring is placed in the groove of the outer ring of the lens group, and then a circle of liquid silicone is uniformly punched along the groove of the inner ring of the lens group. Other process steps are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0076] Only one groove is arranged on the outer periphery of the lens group, one of the sealing ring and the liquid silicone is arranged in the groove, and the other is arranged on the inner or outer periphery of the groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com