Method for exhaust-dyeing wool/cashmere fibers or fabrics by gardenia pigment

A cashmere fiber, gardenia pigment technology, applied in the direction of dyeing method, fiber treatment, animal fiber, etc., can solve the problems of poor color fastness, low dyeing rate, etc., to promote dissolution, improve color fastness, and improve dye utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

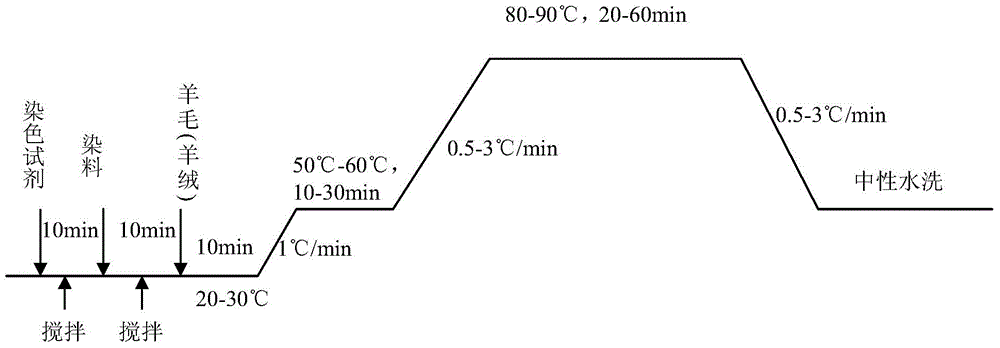

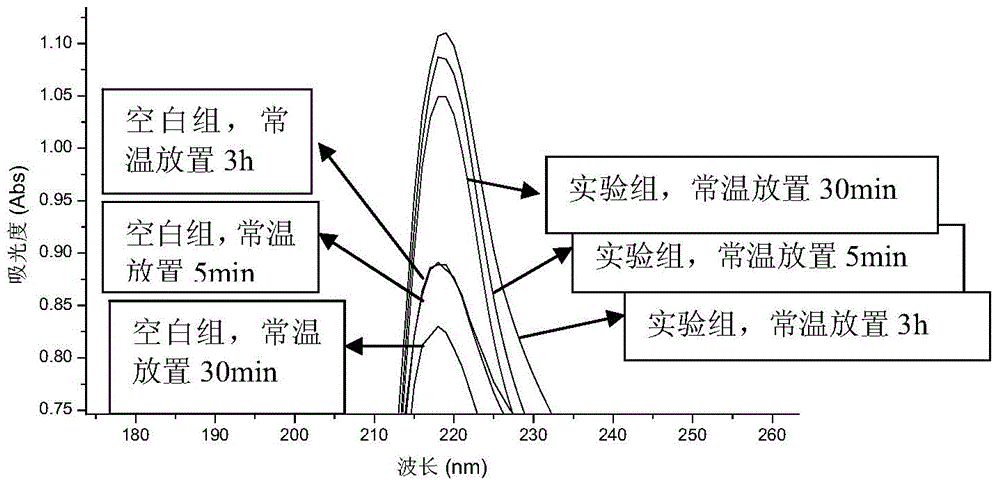

Method used

Image

Examples

Embodiment 1

[0029] Example 1 : Hair strip gardenia red dyed light color

[0030] (1) Wool pretreatment process

[0031] Treatment conditions: take 0.5% fiber weight sodium carbonate, 0.5% fiber weight sodium bicarbonate, 1% fiber weight coconut oil diethanolamide, dissolve in warm water, add wool to it, temperature 50°C, bath ratio 1:30 , wash for 20 minutes, drain, and dry.

[0032] (2) Dyeing process of gardenia red pigment wool

[0033] Dyeing formula: gardenia red pigment 1% (o.w.f),

[0034] Selective reducing agent 0.5g / L,

[0035] Sodium hexametaphosphate 0.02g / L,

[0036] pH is 4-5,

[0037] Bath ratio 1:20,

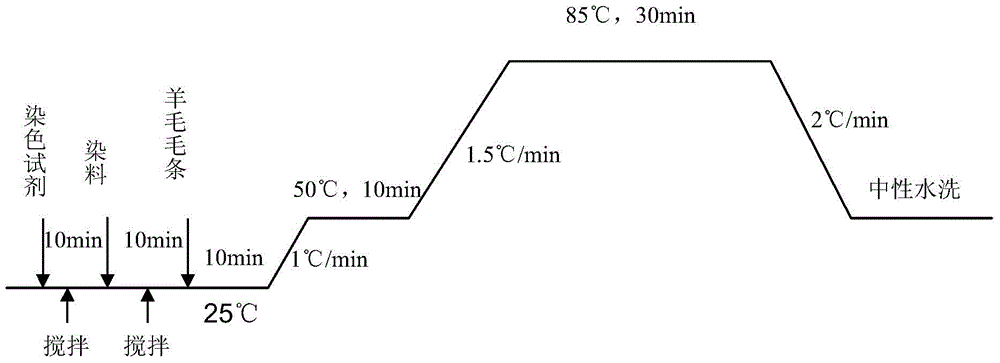

[0038] After the fiber obtained in the first step is manufactured, the top is obtained, and the top is dyed: start heating at 25°C, raise the temperature to 50°C at 1°C / min, keep it warm for 10 minutes, then raise the temperature to 85°C at 1.5°C / min, and keep it warm for 30 minutes , drain at a temperature of 2°C / min, and wait for water washing, such as image 3 s...

Embodiment 2

[0045] Example 2 : Scattered gardenia blue pigmented medium color

[0046] (1) Wool pretreatment process

[0047] Treatment conditions: 1% sodium carbonate by fiber weight, 1.5% coconut oil diethanolamide by fiber weight, after dissolving in warm water, add wool loose fiber to it, temperature 40°C, liquor ratio 1:20, wash for 30 minutes and then drain. Shake fibers dry.

[0048] (2) Dyeing process of gardenia blue plain wool loose fiber

[0049] Dye Formula: Gardenia Blue 2% (o.w.f),

[0050] Efficient selective reducing agent 0.5g / L,

[0051] Sodium hexametaphosphate 0.02g / L,

[0052] pH is 4-5,

[0053] Bath ratio 1:15,

[0054] The dyeing process of the fibers obtained in the first step: Dyeing process: start heating at 30°C, heat up to 50°C at 1°C / min, keep warm for 10 minutes, then heat up to 85°C at 1.5°C / min, keep warm for 40 minutes, and keep warm for 40 minutes at 2 ℃ / min after cooling down, the liquid is drained to be washed with water, such as Figure 4 sh...

Embodiment 3

[0060] Example 3 : Skein gardenia black dye dark color

[0061] (1) Strangulation pretreatment process

[0062] Treatment conditions: take 0.5% of the weight of the yarn weight of sodium bicarbonate and 1% of the weight of the yarn of coconut oil diethanolamide, dissolve it in warm water, add the wool yarn to it, the temperature is 50°C, the bath ratio is 1:20, and wash for 20 minutes After draining, shake dry.

[0063] (2) Gardenia melanin skein dyeing process

[0064] Coloring Formula: Gardenia Melanin 30% (o.w.f),

[0065] Efficient selective reducing agent 1g / L,

[0066] Sodium hexametaphosphate 0.02g / L,

[0067] pH is 5,

[0068] Bath ratio 1:15,

[0069] The dyeing process of the yarn obtained in the first step: Dyeing process: start heating at 30°C, raise the temperature to 60°C at 1°C / min, keep it warm for 20 minutes, then raise the temperature to 90°C at 1°C / min, keep it warm for 60 minutes, and then After cooling down at 2°C / min, drain the liquid and wait fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com