A kind of environment-friendly waterborne polyurethane coating and the wallpaper using the coating

A water-based polyurethane and coating technology, applied in the field of decorative materials and wallpaper, can solve the problems of inability to satisfy consumers' aesthetics, poor three-dimensional effect of wallpaper, and non-alkali-resistant coatings, and achieve good physical and mechanical properties, easy to clean and use. good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An environmentally friendly water-based polyurethane coating includes the following components and the mass ratio of each component is: 36 parts of diisocyanate, 8 parts of epoxy soybean oil, 10 parts of dihydroxymethyl propionic acid, 12 parts of dipropylene glycol, and 9 parts of neopentyl glycol 5 parts, 5 parts of organic bentonite, 4 parts of ethylenediamine, 6 parts of ethylene glycol amine, 4 parts of acetic acid, 4 parts of ternary aziridine, 2 parts of N,N-dimethylcyclohexylamine, the diisocyanate is Mixture of toluene diisocyanate TDI, l,6-hexamethylene diisocyanate HDI, isophordione diisocyanate IPDI, the mixing ratio of l,6-hexamethylene diisocyanate HDI, isophordione diisocyanate IPDI and toluene diisocyanate TDI is 2.5 :1:1.

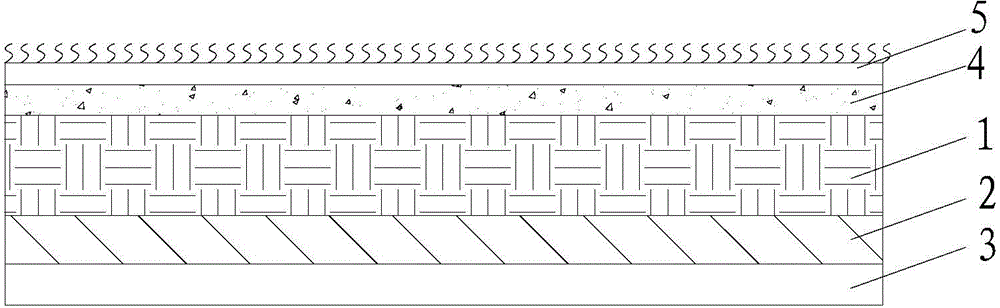

[0024] A wallpaper that adopts an environmentally friendly water-based polyurethane coating, including a base layer 1, an adhesive layer 2, a backing paper layer 3, an environmentally friendly water-based polyurethane coating 4 and a...

Embodiment 2

[0026] An environmentally friendly water-based polyurethane coating includes the following components and the mass ratio of each component is: 34 parts of diisocyanate, 7 parts of epoxy soybean oil, 9 parts of dihydroxymethyl propionic acid, 14 parts of dipropylene glycol, and 10 parts of neopentyl glycol 6 parts of organic bentonite, 3 parts of ethylenediamine, 6 parts of ethylene glycol amine, 3 parts of acetic acid, 2.5 parts of ternary aziridine, 2.5 parts of epoxy silane, 1 part of triethanolamine, 2 parts of N-methylmorpholine Parts, the diisocyanate is a mixture of toluene diisocyanate TDI, 1,6-hexamethylene diisocyanate HDI, isophordione diisocyanate IPDI, 1,6-hexamethylene diisocyanate HDI, isophordione diisocyanate IPDI and toluene diisocyanate The mixing ratio of isocyanate TDI is 2.5:1:1.

[0027] A wallpaper that adopts an environmentally friendly water-based polyurethane coating, including a base layer 1, an adhesive layer 2, a backing paper layer 3, an environme...

Embodiment 3

[0029] An environmentally friendly water-based polyurethane coating includes the following components and the mass ratio of each component is: 37 parts of diisocyanate, 6 parts of epoxy soybean oil, 8 parts of dihydroxymethyl propionic acid, 10 parts of dipropylene glycol, and 9 parts of neopentyl glycol 9 parts of organic bentonite, 3 parts of ethylenediamine, 5 parts of ethylene glycol amine, 3 parts of acetic acid, 3 parts of ternary aziridine, 3 parts of epoxy silane, 1 part of triethanolamine, 2 parts of N-methylmorpholine 1 part, 1 part of pyridine, the diisocyanate is a mixture of toluene diisocyanate TDI, 1,6-hexamethylene diisocyanate HDI, isophordione diisocyanate IPDI, 1,6-hexamethylene diisocyanate HDI, isophordione diisocyanate The mixing ratio of IPDI and toluene diisocyanate TDI is 2.5:1:1.

[0030]A wallpaper that adopts an environmentally friendly water-based polyurethane coating, including a base layer 1, an adhesive layer 2, a backing paper layer 3, an envir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com