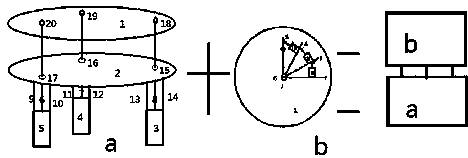

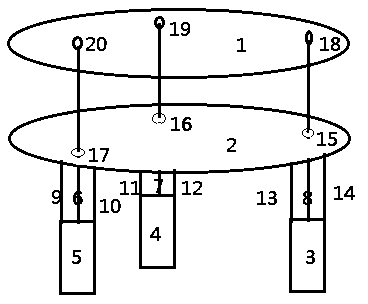

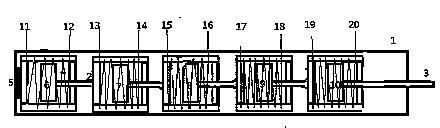

Design method for magnetic latching parallel stepping rotary oscillation joint

A design method and magnetic retention technology, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the problems of high fuel consumption, high air compressibility, and increased structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006]The magnetic holding parallel stepping rotary swing joint is to work under the action of the processor and the encoder, when the processor gives a positive pulse voltage to the magnetic holding drive of a certain unit in the magnetic holding parallel stepping driver, or to the magnetic holding A positive pulse voltage of the unit magnetic holding driver on the parallel stepping rotary disk, through the peripheral circuit, will give the unit magnetic holding driver a positive pulse current, the unit magnetic holding driver will move forward, and the encoder will It will record the state of the magnetic holding drive of this unit, when the processor gives a reverse pulse voltage to a certain unit magnetic holding drive in the magnetic holding parallel stepping drive, or a reverse pulse voltage to the magnetic holding drive of the unit on the magnetic holding parallel stepping rotary disk To the pulse voltage, through the peripheral circuit, a reverse pulse current will be g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com