Automatic-clamping test module

A test module and automatic clamping technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of high labor intensity of workers, poor product positioning accuracy, low degree of automation, etc., saving operation time, clamping and positioning Convenience and the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

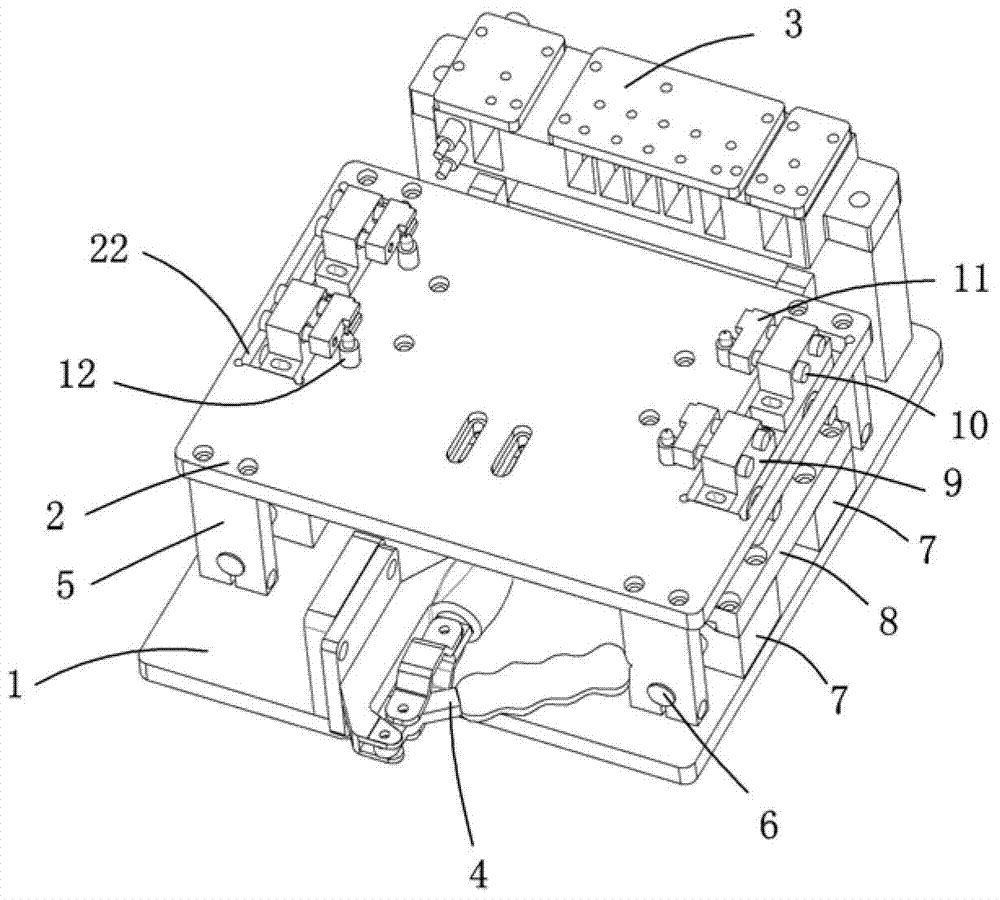

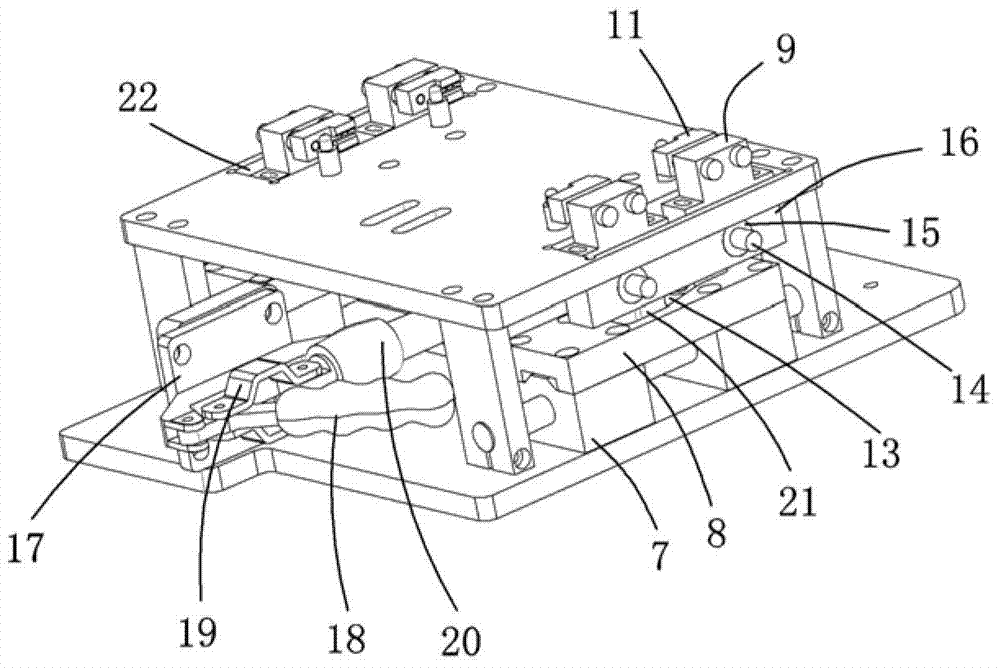

[0017] Examples, see attached figure 1 and 2 , an automatic clamping test module, which includes a base plate 1, a carrier plate 2, a test module 3, a quick clamping device 4, a vertical plate 5, a guide rod 6, a slider seat 7, a groove plate 8, and a clamping and fixing block 9. Contour screw 10, collet 11, support positioning pin 12, cam bearing 13, side guide rod 14, bearing 15 and clamping seat 16, the test module and quick clamping device are connected to the bottom plate, and the quick clamping device The upper side is connected with the carrier plate, and the quick clamp device can drive the carrier plate to move forward; the quick clamp device includes a fixed plate 17, a quick clamp 18, a connecting piece 19 and a connecting plate 20, and the fixed plate is fixed on the bottom plate On the top, the end of the quick clamp is hinged with the fixed plate, the middle part of the quick clamp is hinged with two connecting pieces, the two connecting pieces are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com