Welding connection method of aluminum-alloy pipelines of same diameter

A technology of welded connection and aluminum alloy tubes, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced mechanical properties, large expansion coefficient, and harmful performance, so as to increase the effective bearing area and improve the welding strength , Operation and implementation of simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

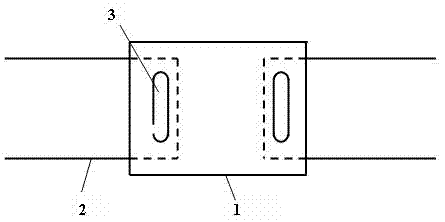

[0039] In this embodiment, the base metal is two φ208×4mm aluminum alloy pipes 2024, and a φ212×5mm aluminum alloy pipe joint 2024, through the following steps:

[0040] (1) On both sides of the pipe joint, 3 equidistant groove-shaped through holes are respectively opened along the circumferential direction. The center line of the groove-shaped through-hole is perpendicular to the axis of the pipe joint. The spacing is not less than the hole length of each groove-shaped through hole; and then a 60° bevel is processed on the inner surface of both ends of the pipe joint;

[0041] (2) First use acetone to remove the oil stains on the surface of the pipe joint and the end of the aluminum alloy pipe, the wall of the grooved through hole, the joint surface of the grooved through hole and the lower plate, etc., and then use sandpaper to mechanically polish the above to be welded area, polished until the metallic luster is revealed, and finally wiped clean with a clean cotton gauze; ...

Embodiment 2

[0061] In this embodiment, the base metal is two φ208×4mm aluminum alloy pipes 2024, and a φ212×5mm aluminum alloy pipe joint 2024, through the following steps:

[0062] (1) On both sides of the pipe joint, 4 equidistant groove-shaped through holes are respectively opened along the circumference. The center line of the groove-shaped through-hole is perpendicular to the axis of the pipe joint. The spacing is not less than the hole length of each groove-shaped through hole; and then a 50° bevel is processed on the inner surface of both ends of the pipe joint;

[0063] (2) First use acetone to remove the oil stains on the surface of the pipe joint and the end of the aluminum alloy pipe, the wall of the grooved through hole, the joint surface of the grooved through hole and the lower plate, etc., and then use sandpaper to mechanically polish the above to be welded area, polished until the metallic luster is revealed, and finally wiped clean with a clean cotton gauze;

[0064] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com