Gun perforation block cap of oil well perforator and producing method thereof

A perforator and hole plugging technology, which is applied in the direction of bonding method, earthwork drilling, wellbore/well parts, etc., can solve the problems of poor perforation effect, etc., and achieve improved perforation effect, high hardness, and effective increase The effect of pressure-bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

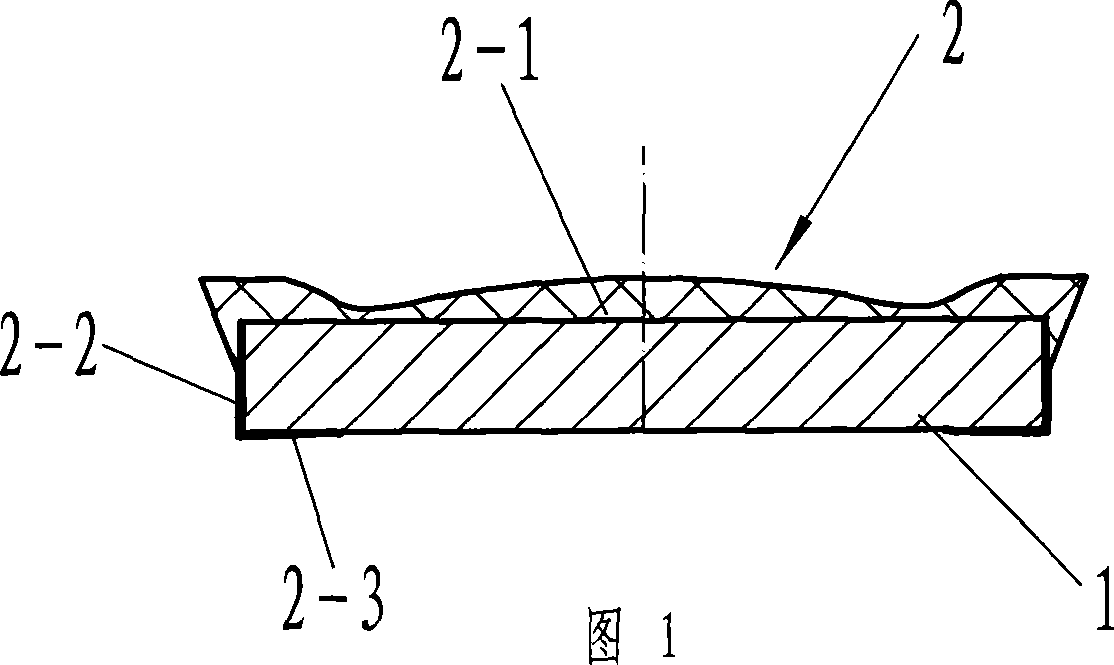

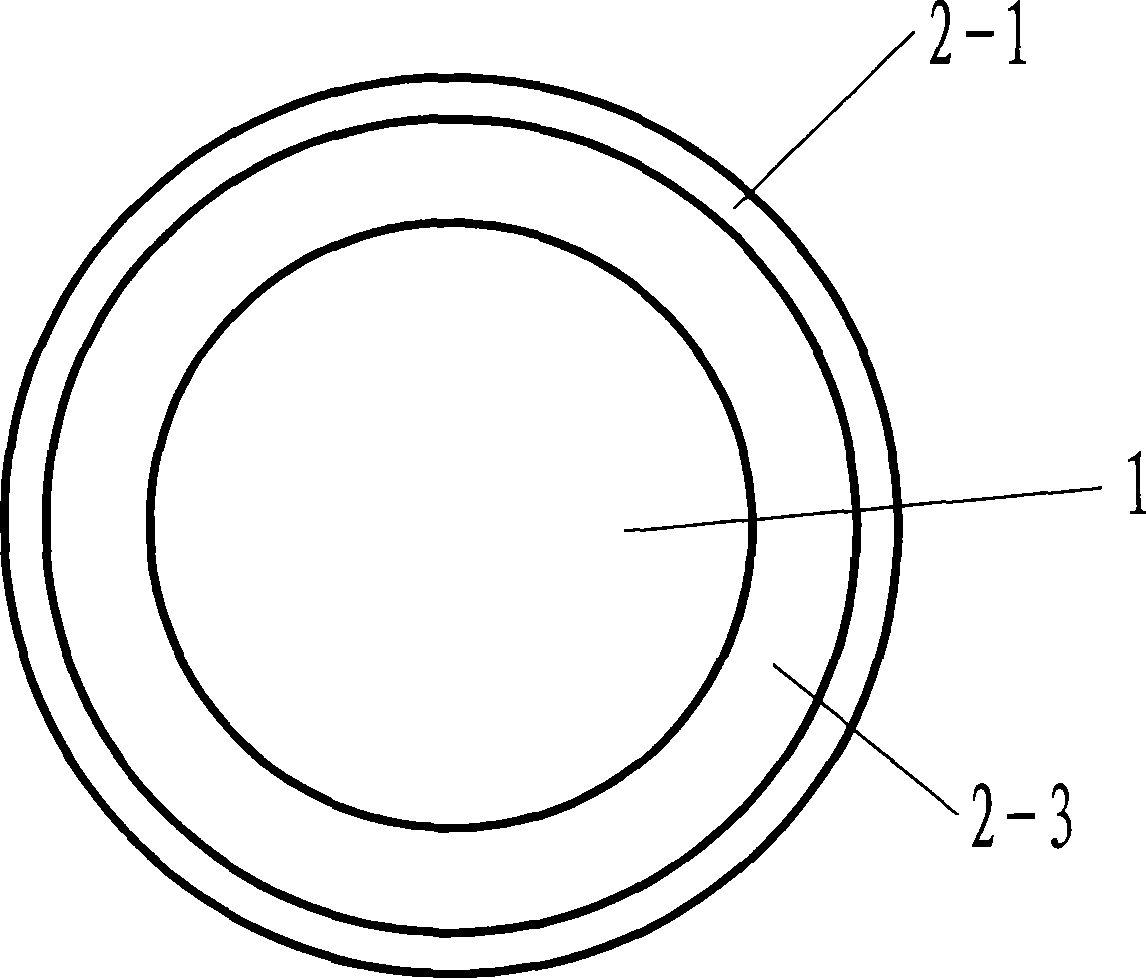

[0022] Referring to Figures 1 and 2, it has a ceramic disc 1 matching the perforation aperture, and a rubber sealing layer molded by rubber vulcanization hot molding is provided on the upper end surface, the outer circumference and the outer ring of the bottom surface of the disc. 2, wherein the rubber sealing layer 2-1 on the upper end surface of the disc is in the shape of a molded cover, and is located on the outer circumference of the disc 2-2 and as figure 2 The shown bottom outer ring 2-3 is a vulcanized rubber thin layer molded. The rubber sealing layer 2 can make the perforation plug have good sealing performance.

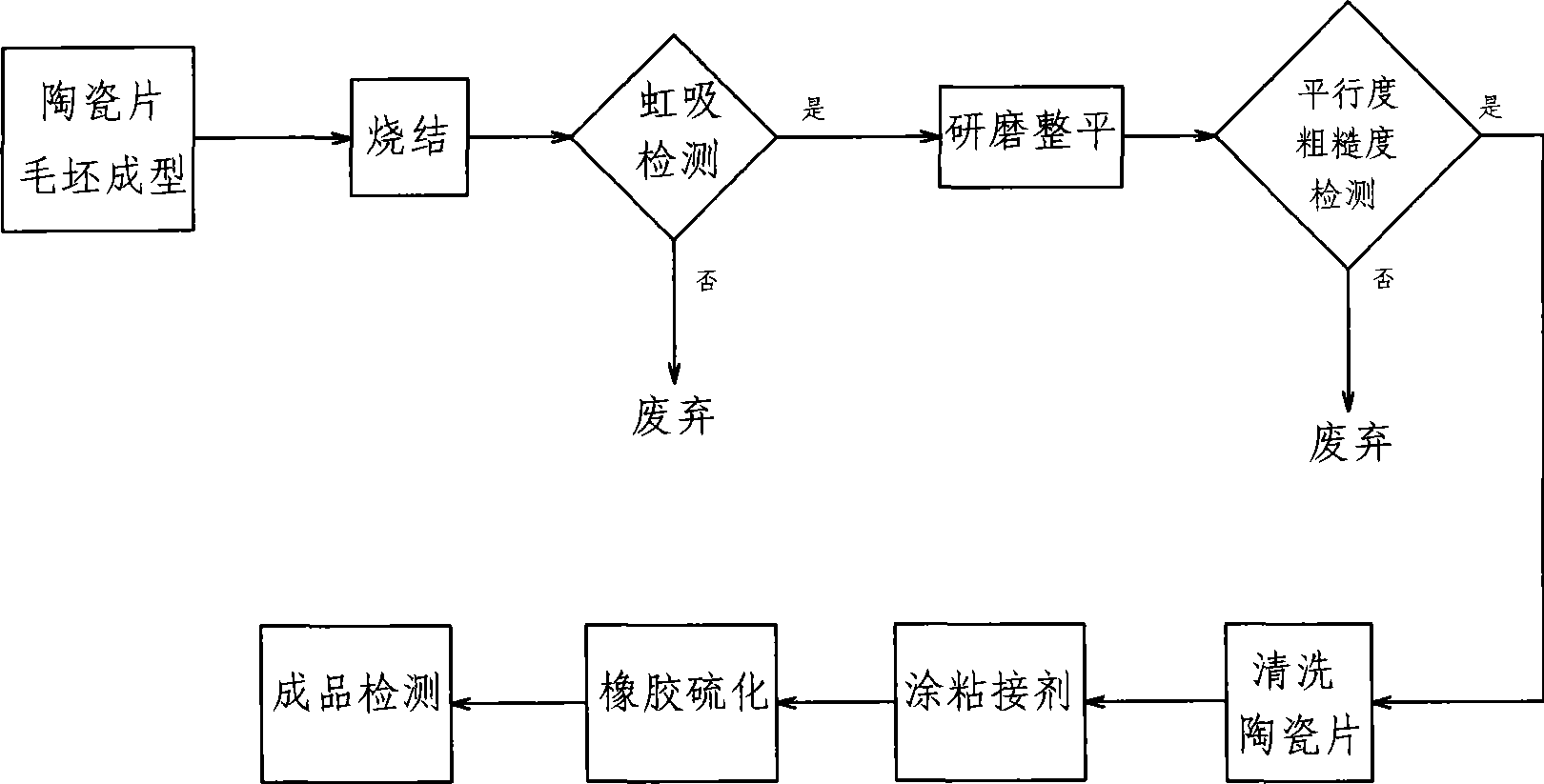

[0023] see figure 2 , the production steps of this perforation plugging cover are as follows:

[0024] 1. Dry pressing with a mold to make a ceramic disc blank;

[0025] 2. Sinter the ceramic disc blanks into ceramic discs;

[0026] 3. Use the siphon method to detect the surface cracks and internal dark cracks of the ceramic sheet. If there are cracks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com