Brazing method of large area cemented carbide with standing wave confinement

A technology of cemented carbide and brazing method, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of cemented carbide cracking, large stress, scrapping of workpieces, etc., so as to improve the brazing rate and improve the connection strength. , to ensure the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

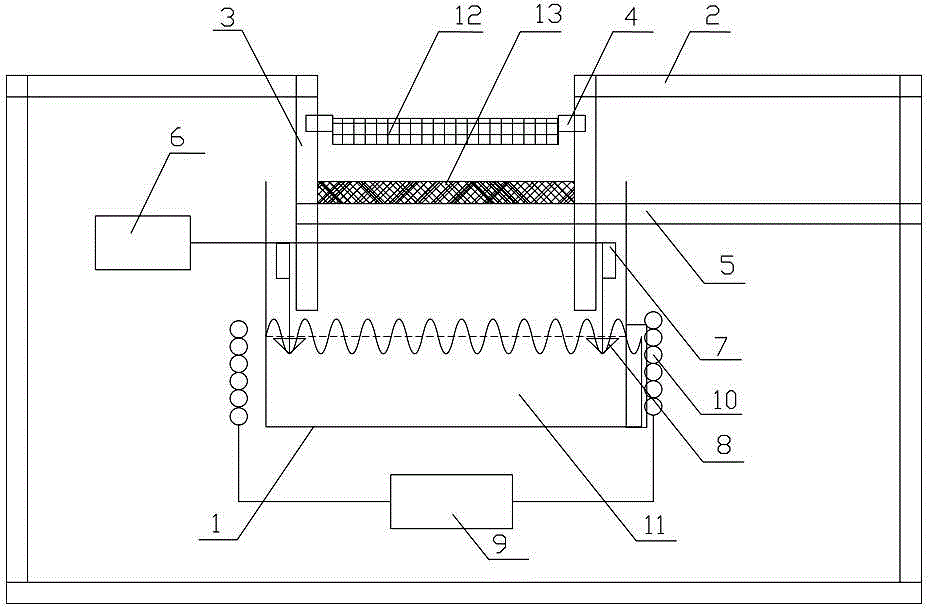

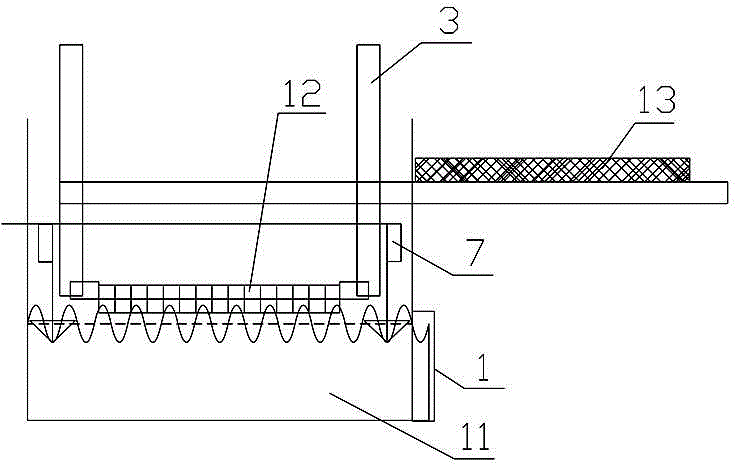

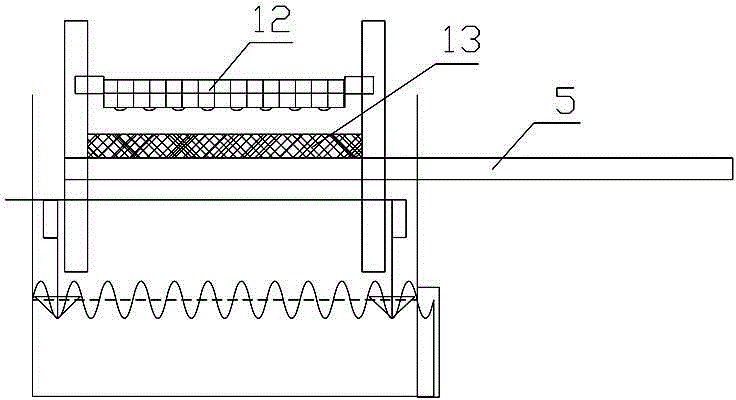

[0018] Such as figure 1 As shown, the special brazing device with a standing wave generating device of the present invention includes a crucible 1 and a heating device that is placed outside the crucible 1, and the heating device is composed of an induction coil 10 that is controlled by a power supply 9 and surrounds the outside of the crucible; the crucible 1 A support truss 2 is arranged outside, and a group of vertical guide rails 3 extending into the crucible 1 are arranged on the support truss above the crucible, and the alloy block clamping device 4 moves up and down along the vertical guide rails 3; A horizontal guide rail 5 extending into the crucible is provided; a standing wave generating device is provided in the crucible 1: the standing wave generating device is an oscillating motor 7 controlled by a waveform control system 6 and driven by the oscillating motor 7 and evenly distributed on the crucible 1 The inner ceramic oscillating plate 8.

[0019] In order to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com