Large-size multi-axis-linkage electrolytic machine tool

An electrolytic machining machine tool and multi-axis linkage technology, which is applied in the direction of electric processing equipment, electrochemical processing equipment, metal processing equipment, etc., can solve the problems of difficult adjustment of processing parameters, low degree of integration, low degree of flexibility, etc., and achieve reduction The effect of the number of operators, large operating space and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

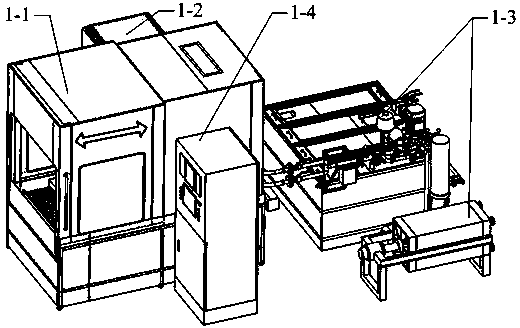

[0031] Please refer to figure 1 As shown, the large-scale multi-axis linkage electrolytic machining machine tool of the present invention includes a machine tool body 1-1, an electrolytic machining pulse power supply 1-2, an electrolyte circulation filtering system 1-3, and an integrated control system 1-4.

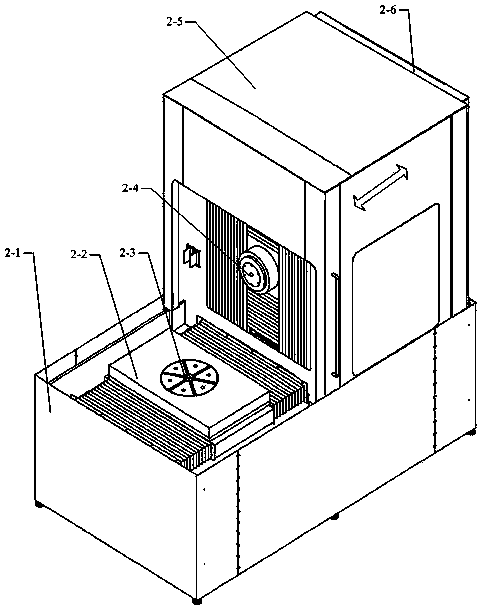

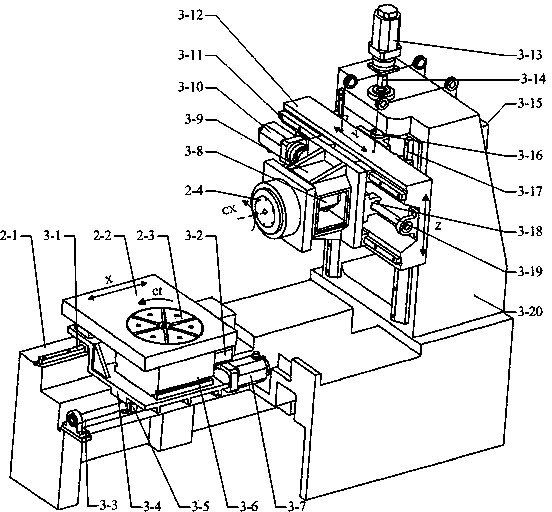

[0032] Please refer to figure 2 and image 3 As described, the machine tool body 1-1 includes a bed 2-1, a horizontal workbench 2-2, a turntable 2-3, a main shaft 2-4, a working box 2-5 and a machine tool cover 2-6, the turntable 2-3 and the horizontal The workbench 2-2 is made of marble, and the turntable 2-3 is connected with the CNC rotary table 3-6 through a short axis. The above-mentioned CNC rotary table 3-6 can be purchased from Yantai Universal Machine Tool Accessories Company. The machine tool can realize five-axis linkage, They are respectively the X-direction movement of the horizontal table 2-2, the ct-direction rotation of the turntable 2-3, and the cx-dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com