Preparation method for low-agglomeration antioxidant copper nanoparticle powder

A nano-copper powder and anti-oxidation technology, which is applied in the field of low-agglomeration and anti-oxidation nano-copper powder, can solve the problems of nano-copper powder agglomeration, oxidation, and inability to solve oxidation resistance and dispersibility well, and achieve low production cost, Great economic benefits, avoiding agglomeration and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

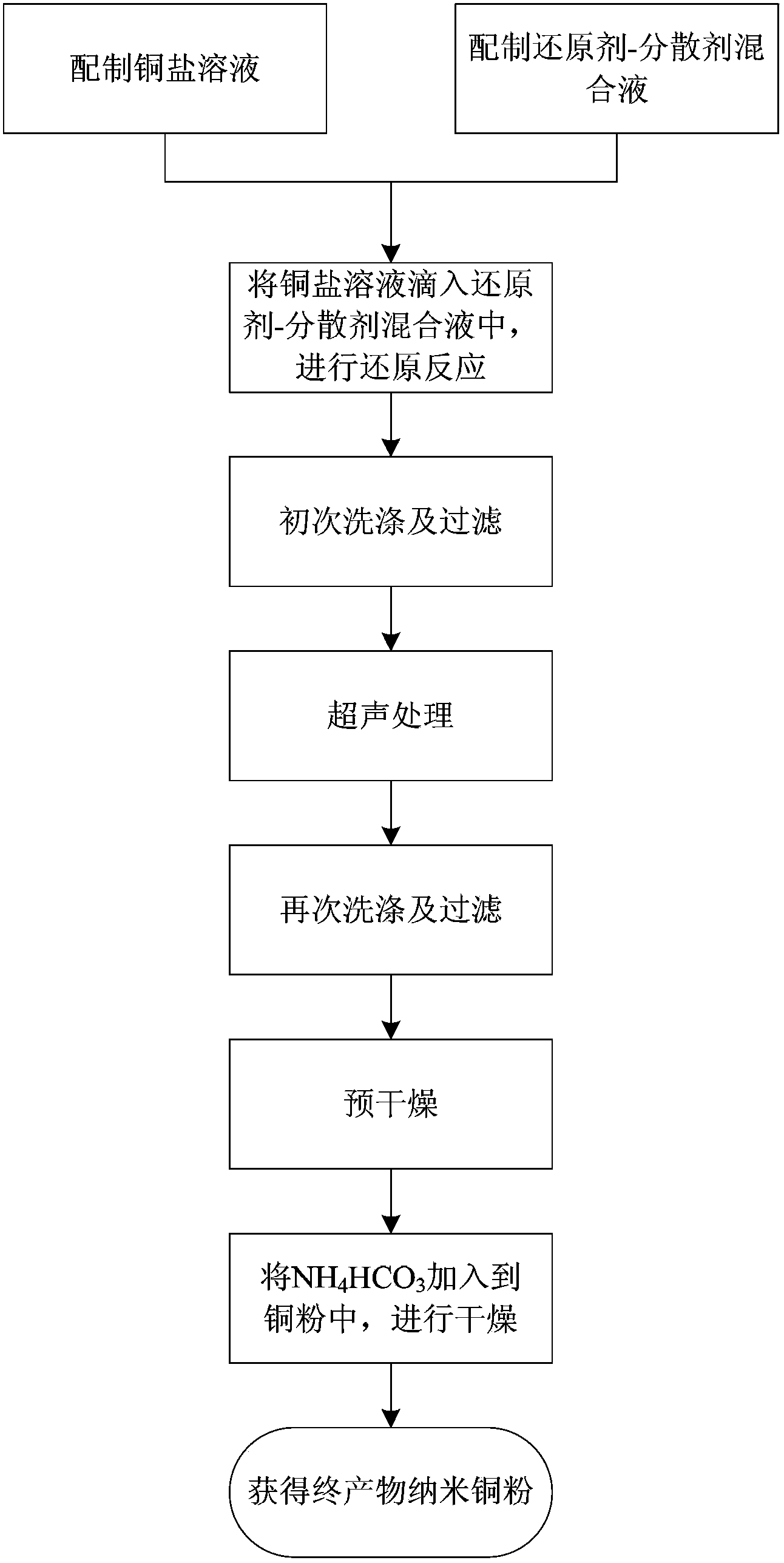

[0024] Such as figure 1 As shown in the process flow diagram, the present invention provides a method for preparing low-agglomeration anti-oxidation nano-copper powder, comprising the following steps:

[0025] The preparation step is to prepare copper salt solution and reducing agent-dispersant mixed solution respectively, wherein the copper salt solution is obtained by dissolving copper salt in water, and the concentration of Cu ions in the copper salt solution is 10-50 g / L, and the reduction The agent-dispersant mixture is obtained by adding the dispersant into the hydrazine hydrate solution with a concentration of 3-3.5mol / L, ultrasonically vibrating, and mixing uniformly. The dispersant can be any one of the following materials: poly Oxyethylene sorbitan monooleate, gelatin, sodium lauryl sulfate, fatty acid polyethylene glycol fat, etc., wherein polyoxyethylene sorbitan monooleate is preferably used, and the addition amount of the dispersant is copper 1% to 5% of the mas...

Embodiment 1

[0036] (1) Dissolve CuSO with deionized water 4 ·5H 2 O is made into copper salt solution, wherein the concentration of Cu ions is 30g / L, about 1000mL is ready for use.

[0037] (2) Add 0.3 g of polyoxyethylene sorbitan monooleate into the hydrazine hydrate solution, and ultrasonically vibrate to form a uniform reducing agent-dispersing agent mixture.

[0038] (3) According to the molar ratio Cu: N 2 h 4 =1: 1.5, add the copper salt solution dropwise to the above-mentioned reducing agent-dispersant mixed solution, adjust the pH of the solution to 11 with 10% NaOH solution by mass percentage, raise the temperature to 70°C, and Keep the reaction until the supernatant turns colorless, that is, the reaction is over, let stand, remove the supernatant, and leave the precipitate.

[0039] (4) Under nitrogen protection conditions, the precipitate obtained in step (3) was washed with deionized water and absolute ethanol in sequence, and centrifugally filtered to obtain the precipit...

Embodiment 2

[0046] (1) Dissolve copper chloride in deionized water to make a copper salt solution, in which the concentration of Cu ions is 30g / L, about 1000mL is ready for use.

[0047] (2) Add 0.6 g of polyoxyethylene sorbitan monooleate into the hydrazine hydrate solution, and ultrasonically vibrate to form a uniform reducing agent-dispersing agent mixture.

[0048] (3) According to the molar ratio Cu: N 2 h 4 = 1: 2.5 The dosage ratio of the copper salt solution is added dropwise to the above-mentioned reducing agent-dispersant mixed solution, the pH of the solution is adjusted to 12 with a 15% NaOH solution by mass percentage, and the temperature is raised to 75 ° C. Keep the reaction under the same conditions until the supernatant turns colorless, that is, the reaction ends, let stand, remove the supernatant, and leave the precipitate.

[0049] (4) Under nitrogen protection conditions, the precipitate obtained in step (3) was washed with deionized water and absolute ethanol in seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com